A Headspace Gas Chromatography Method for Detecting the Exchange Capacity of Ion Exchange Resins

A technology of headspace gas chromatography and ion exchange resin, applied in the field of headspace gas chromatography, can solve the problems of difficult identification of titration end point, complicated operation process, large error, etc., and achieve the effect of shortening the detection time and rapid detection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 5

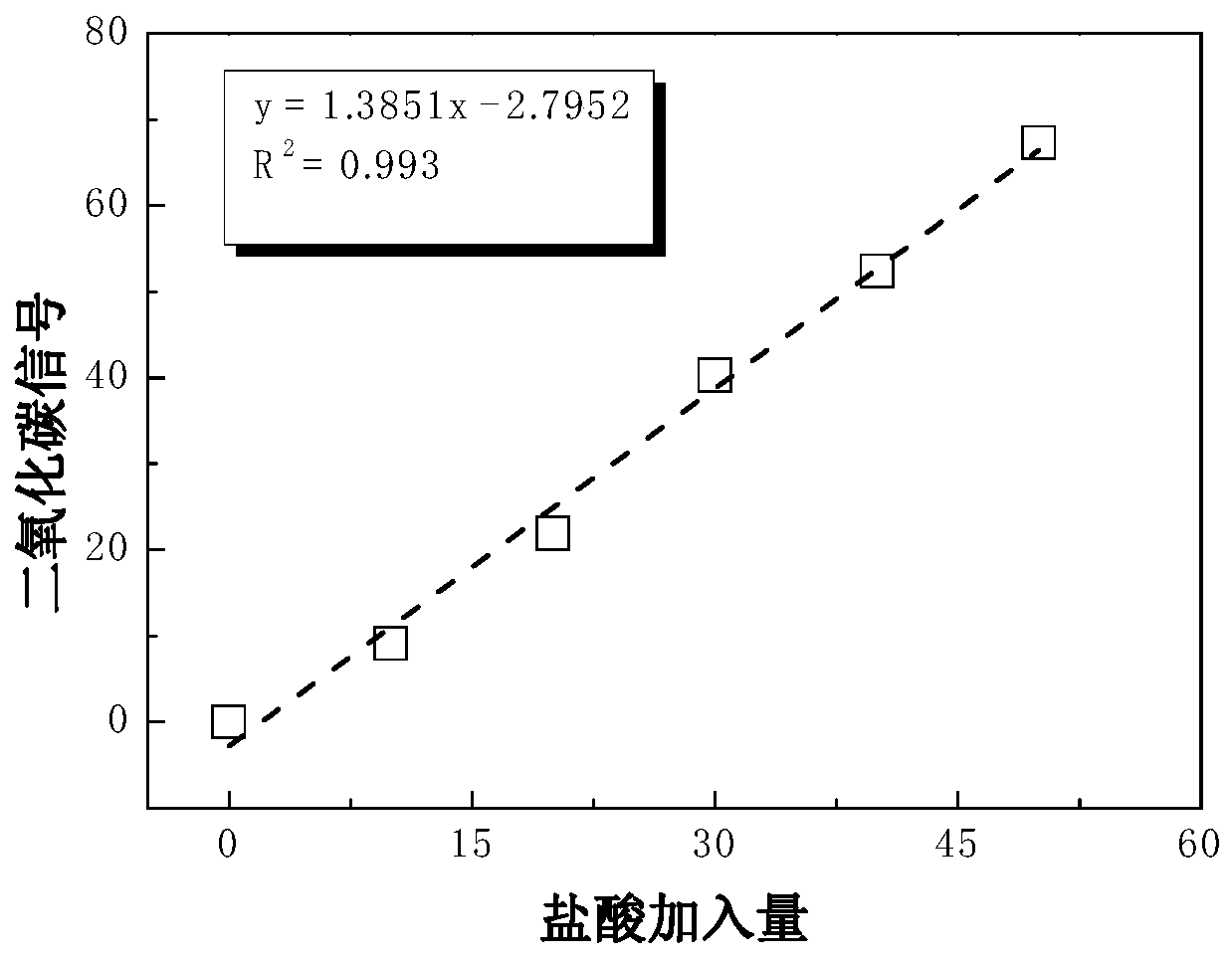

[0100] (51) Weakly basic anion exchange resin sample preparation

[0101] Take two portions of 0.5g (accurate to 0.001g) of hydroxide type weak base anion exchange resin in a 50ml dry corked Erlenmeyer flask, use a pipette to draw 25ml 0.1mol / L hydrochloric acid standard solution into the corked Erlenmeyer flask, shake Mix well, cover tightly, soak in 40°C water bath for 2 hours, take it out, and cool to room temperature. Filter with a strainer and take the filtrate. Use a 100ul micro-syringe to draw 200ul (twice) filtrate to pierce the rubber septum, inject it into a headspace bottle filled with 3ml 0.05mol / L sodium bicarbonate solution, shake well, and wait for the test.

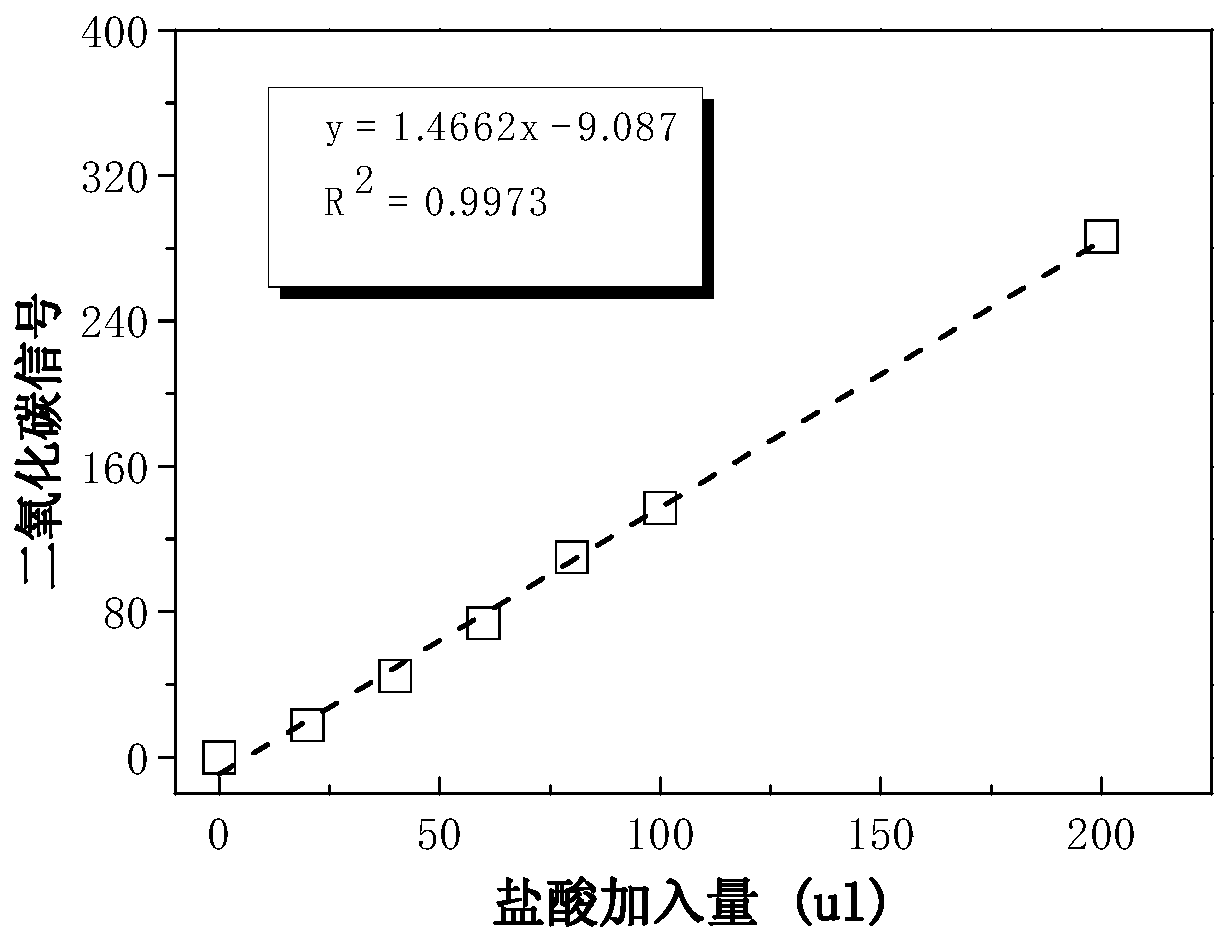

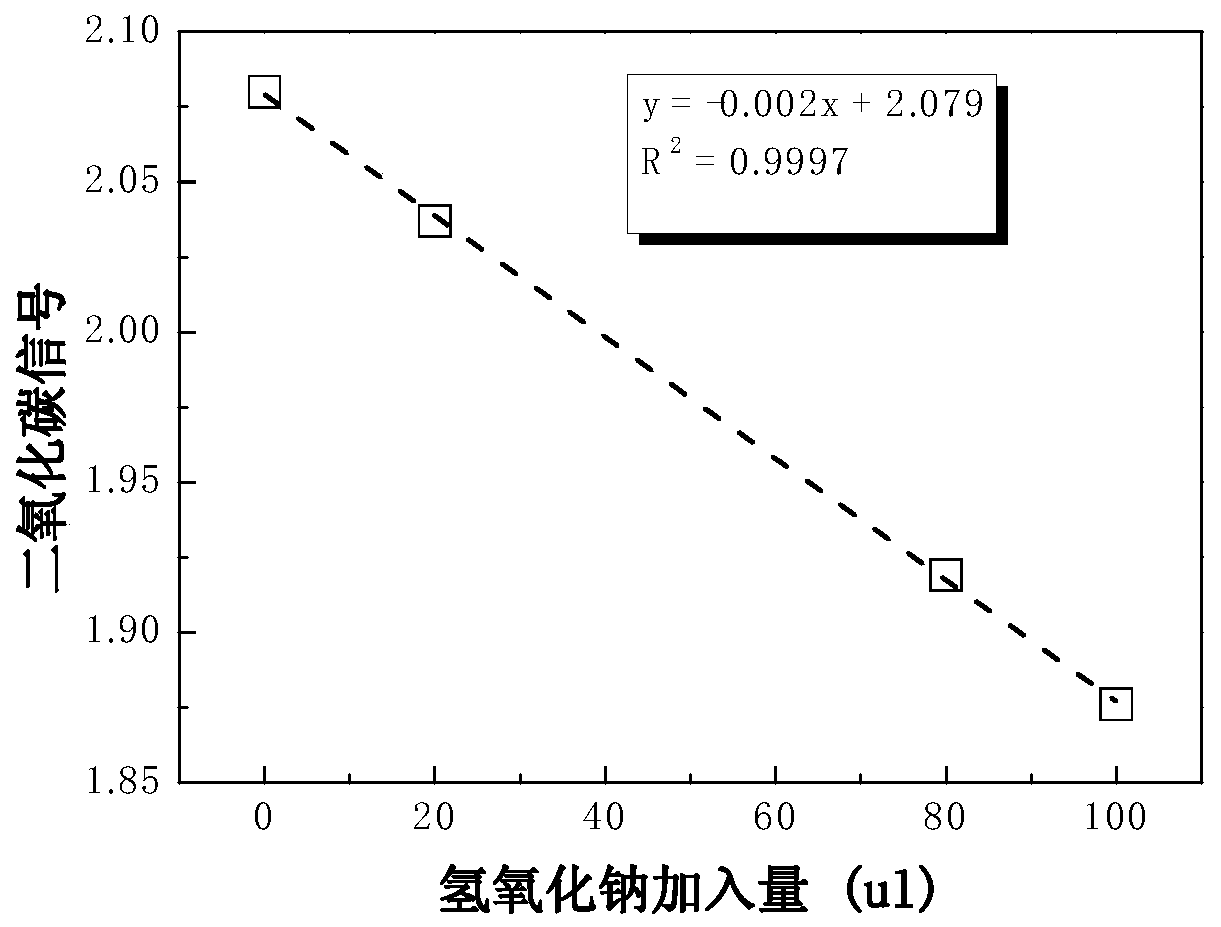

[0102] (52) Establish standard curve

[0103] React with the sodium bicarbonate solution in the step (51) with the hydrochloric acid standard solution of known different concentrations, place the headspace bottle, then carry out the reaction described in the step (51); After processing, will contain the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com