Automatic quantitative steel ball measuring device

An automatic and steel ball technology, applied to measuring devices, mechanical devices, instruments, etc., can solve time-consuming and labor-intensive problems, save time and manpower, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

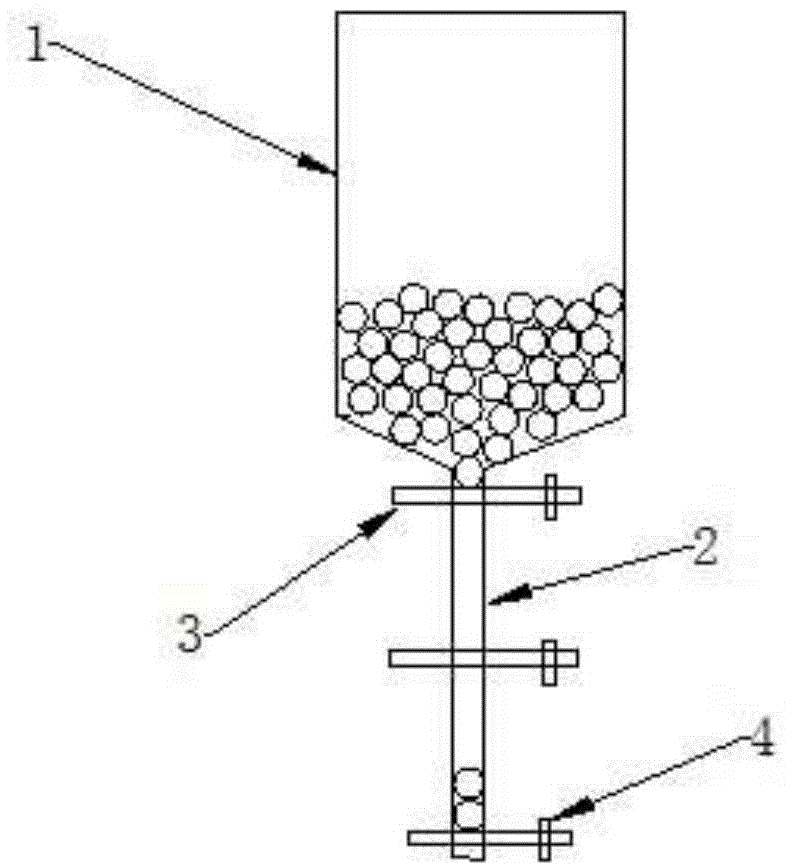

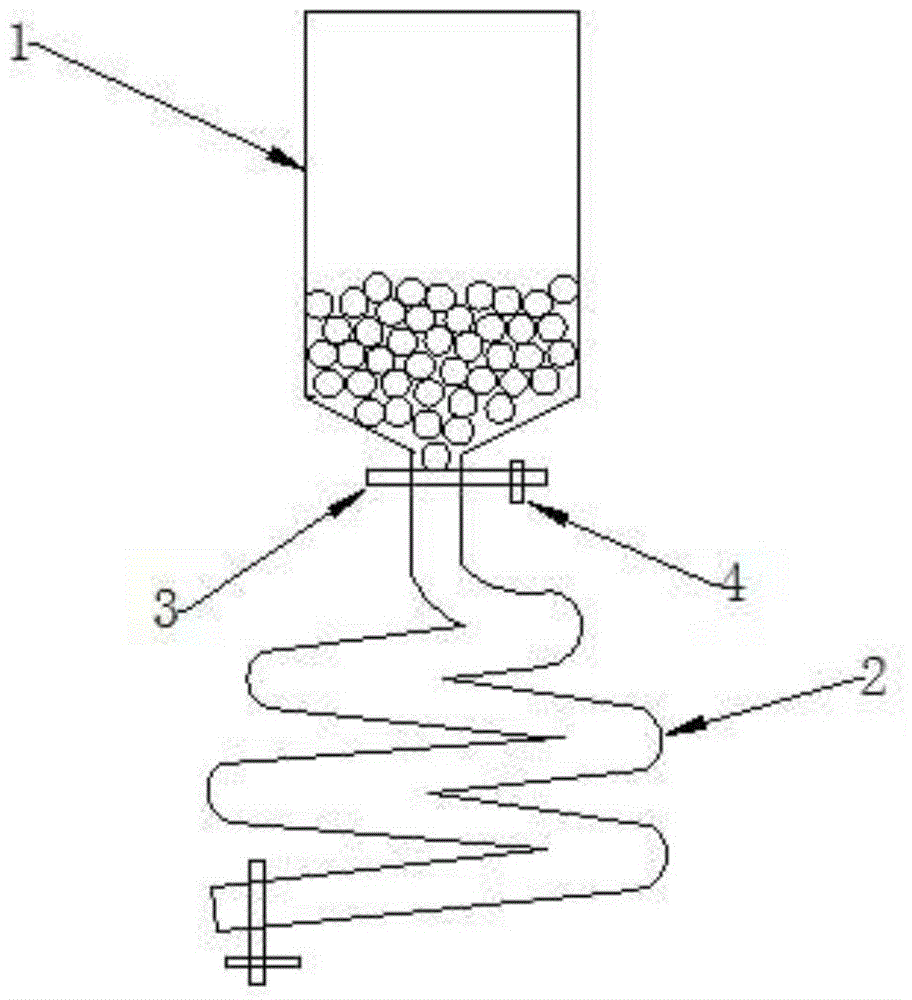

[0016] An automatic quantitative measuring device for steel balls is provided, comprising:

[0017] A steel ball containing container 1, the lower part of the steel ball containing container 1 has a through hole, the through hole and the steel ball clearance fit; effectively ensure that the steel ball can enter the steel ball measuring tube through the through hole.

[0018] A steel ball measuring tube 2, the steel ball measuring tube 2 is a hollow tube and one end communicates with the lower through hole of the steel ball containing container, the steel ball measuring tube 2 has a plurality of gate through holes with a diameter smaller than the steel ball diameter , the area of the through hole of the gate is smaller than the maximum cross-sectional area of the steel ball, and the through hole of the gate is equipped with a gate 3 that is matched with it and can be freely loaded and removed. number of steel balls. Guaranteed to quickly take out the desired number.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com