Method for predicting paper surface matte degree

A matte and degree technology, applied in transmittance measurement and other directions, can solve the problems of unpredictable matte degree of paper surface and material waste, and achieve the effect of being conducive to installation and fixation, ensuring quality and ensuring reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

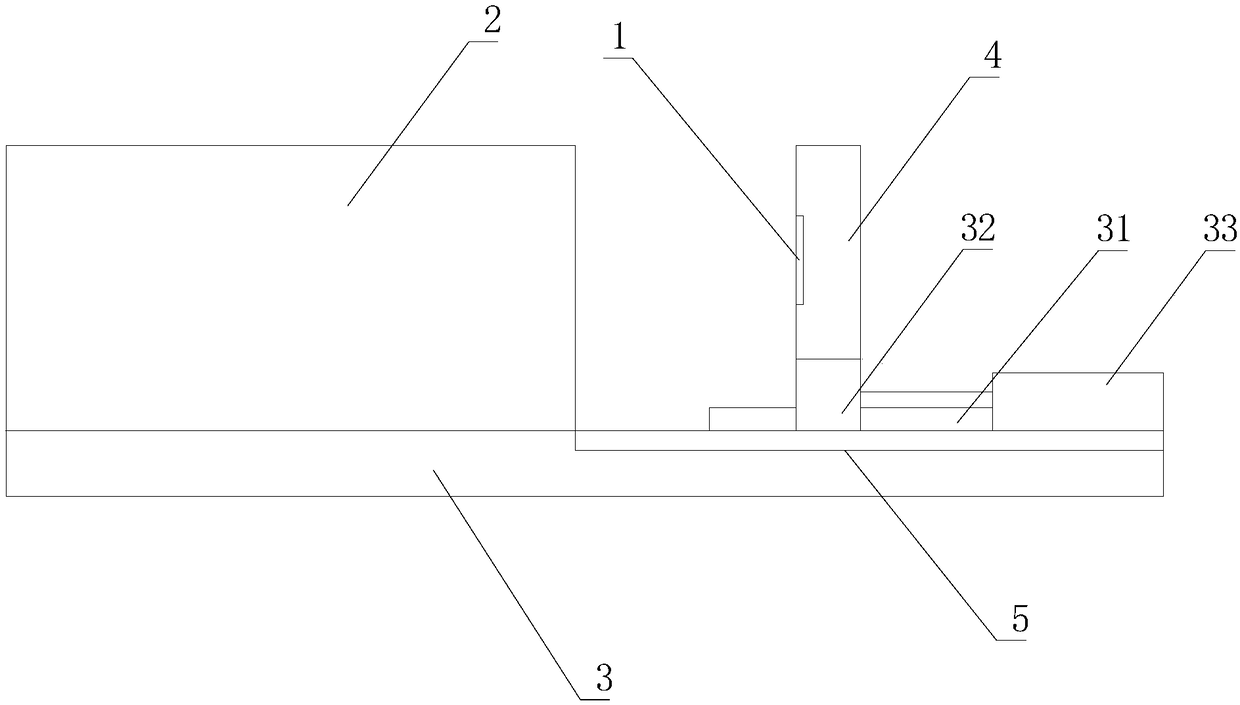

[0022] A method for predicting the matte degree of paper surface, comprising the following steps;

[0023] Step 1: cutting the transfer film sample, and obtaining the test area S of the transfer film sample;

[0024] Step 2: Pass the transfer film sample cut in step 1 through a light transmittance haze meter to obtain the haze H and light transmittance T of the transfer film sample;

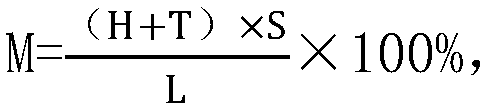

[0025] Step 3: Calculate the matte degree M of the transfer film according to the test area S obtained in step 1, and the haze H and light transmittance T obtained in step 2. The matte degree M is calculated by the following formula:

[0026]

[0027] Where L is the distance between the light transmittance haze meter and the transfer film sample.

[0028] Since the transfer film is directly coated on the paper during the paper production process, the matte degree M of the transfer film is an important factor in determining the matte degree of the finished paper. It is possible to predict the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com