Construction method of an underground special-shaped pool

A construction method and pool technology, applied in water conservancy projects, excavation, artificial islands, etc., can solve problems such as time-consuming and laborious, poor construction environment, impact on life and production, improve work efficiency, reduce underground construction time, convenient and practical operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

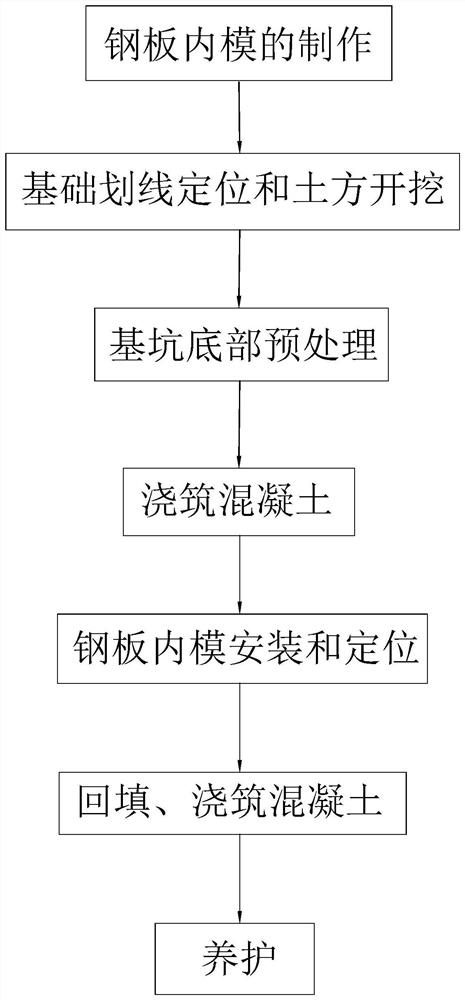

[0044] A construction method for an underground special-shaped pool, such as figure 1 shown, including the following steps:

[0045] a. Production of steel plate inner mold: First, according to the construction needs, a barrel-shaped steel plate inner mold with only an upper end opening is made on the flat ground or in the factory workshop by lap welding or full welding. The barrel-shaped steel plate inner mold can be used to hold For water or other liquids, compared with the previous pouring of concrete pool structures in foundation pits, the construction difficulty coefficient is significantly reduced, and the actual construction time in foundation pits is greatly shortened, thereby improving construction efficiency and improving construction conditions.

[0046] Then, according to the different materials in the special-shaped pool, the inner and outer surfaces of the inner mold of the steel plate are subjected to anti-corrosion treatment. Layer arc spraying anti-corrosion ...

Embodiment 2

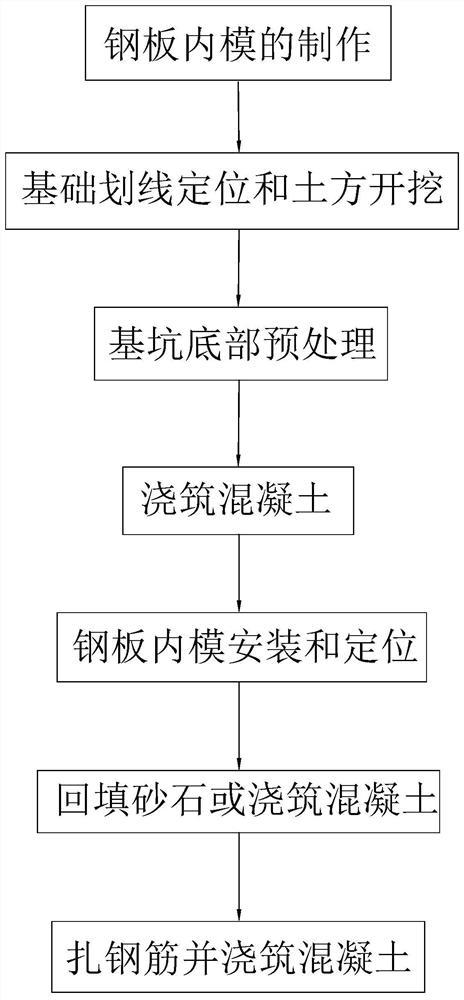

[0055] A construction method for an underground special-shaped pool, such as figure 2 As shown, the difference from Example 1 is that when backfilling in step f, the general soil collapse or severe landslide will occur about 3-4 days after the excavation of the earth, and the operator can also lightly press the inner mold around its steel plate. Sprinkling a layer of sand and gravel mixture on the ground can reduce the probability of soil collapse and improve the safety of underground pool construction. In addition, when using sand and gravel mixture for backfilling, the operator needs to go through 7-10 days of maintenance before filling. Drain the water in the gravel, and use a tamping machine to tamp the gravel until it is flush with the opening at the upper end of the inner mold of the steel plate.

[0056] When binding steel bars and pouring concrete in step g, tie steel bars at the top edge of the steel plate inner formwork, erect a concrete cover plate with reserved ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com