Power detection device of laser device

A technology of power detection and laser power, applied in the direction of using electric radiation detectors for photometry, etc., can solve the problems of deviation of detection data, high production cost, inaccurate detection results, etc., to reduce energy loss, improve detection accuracy, reduce energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the embodiments given in the accompanying drawings.

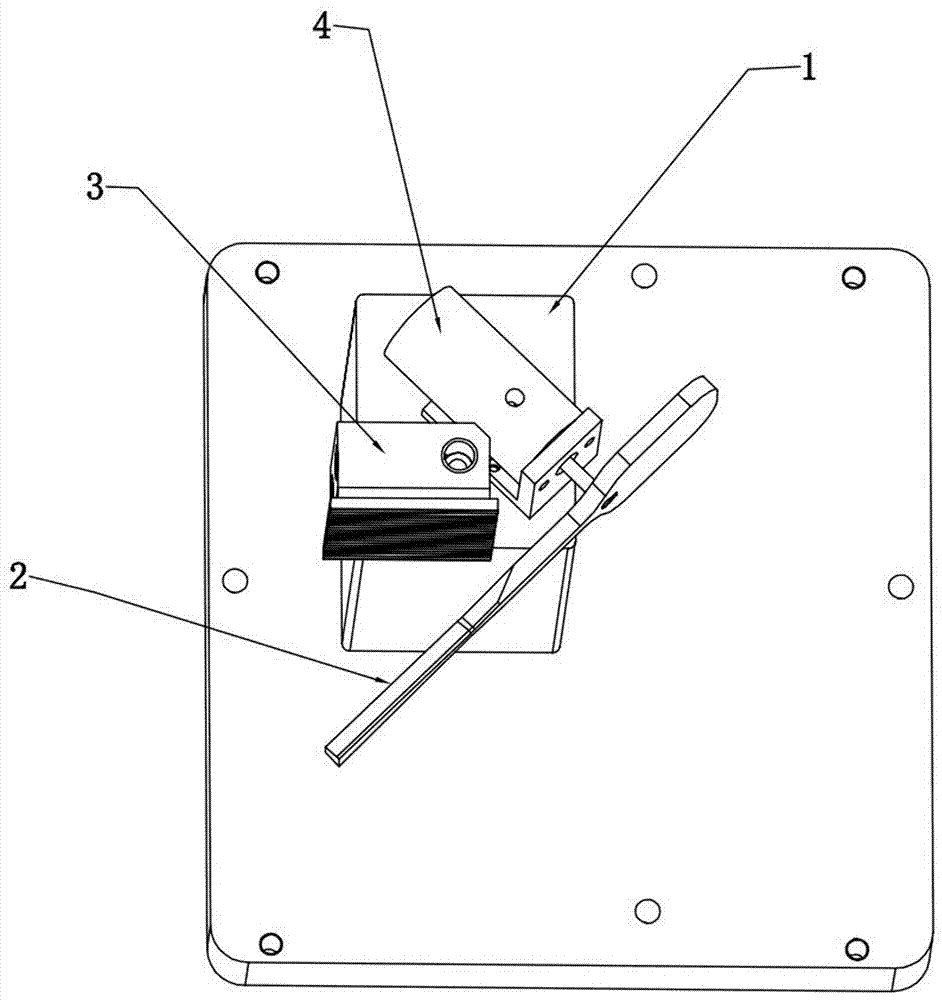

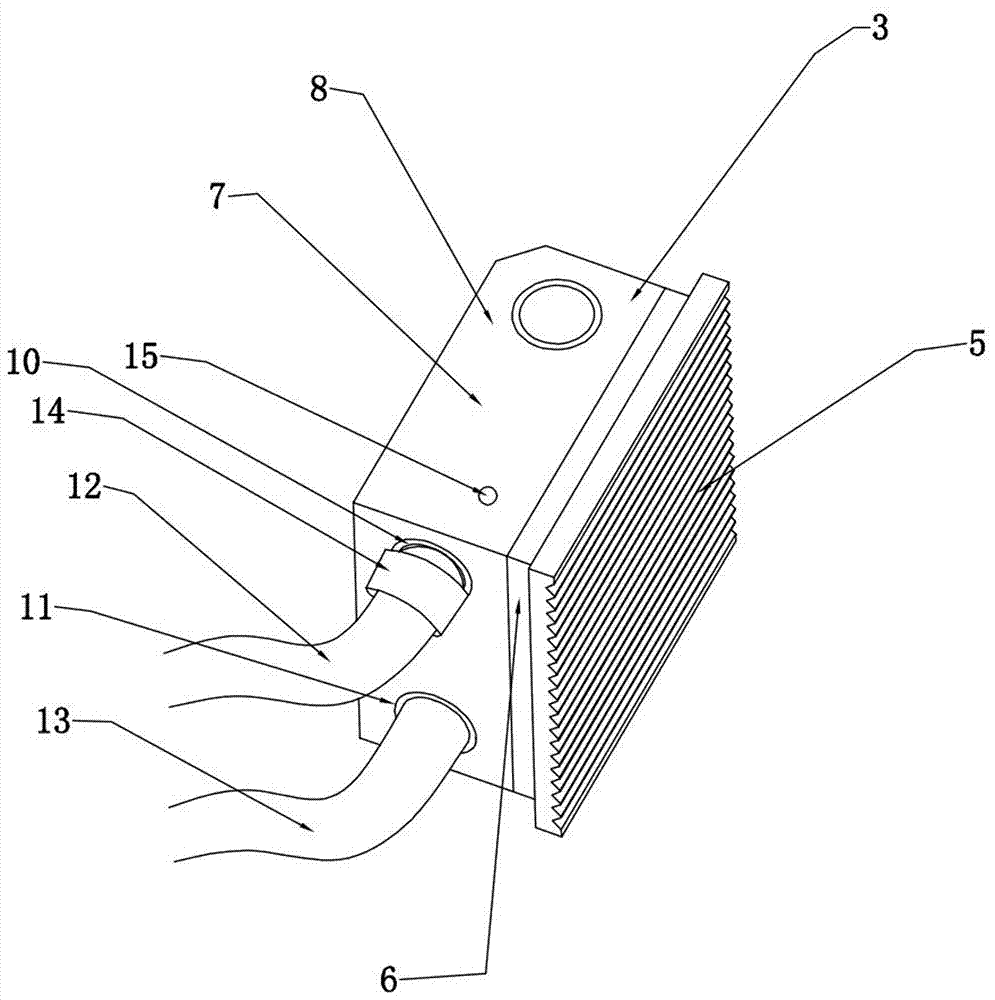

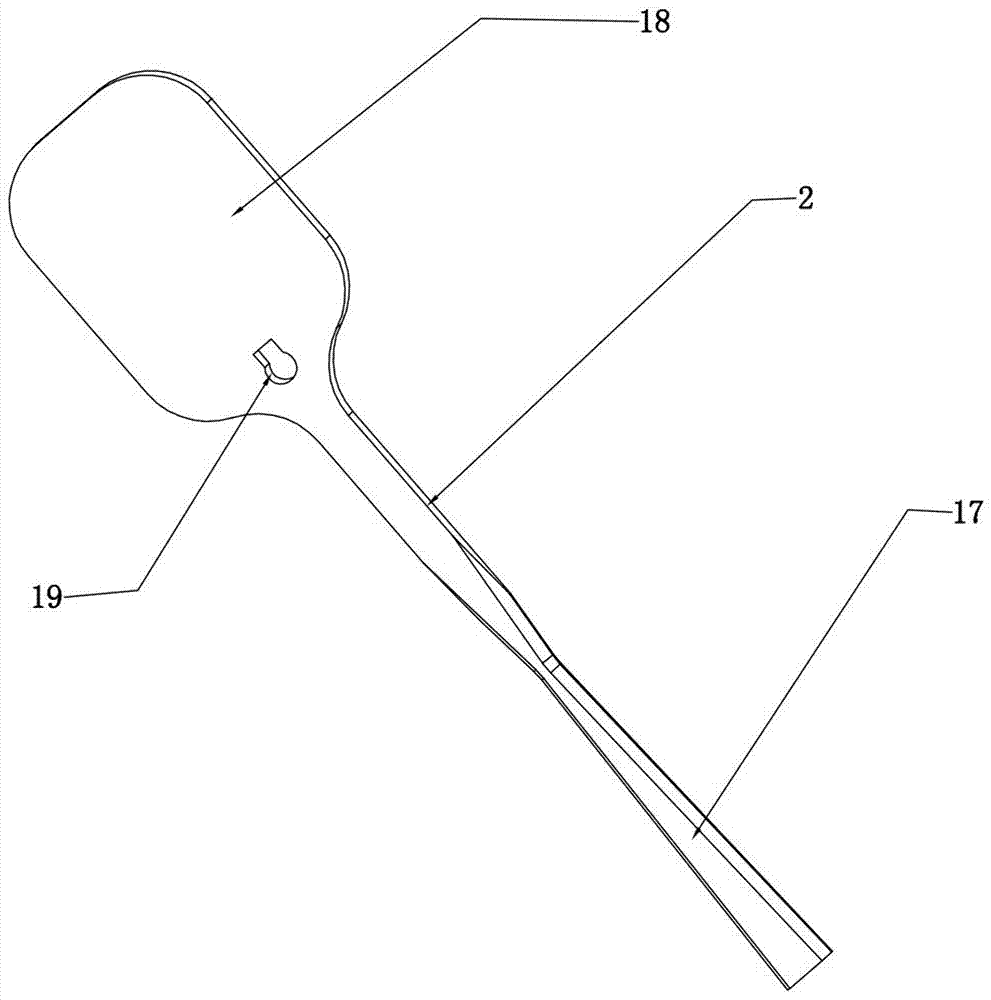

[0032] refer to Figure 1-6 As shown, a laser power detection device disclosed in this embodiment includes a power detection assembly 1, the power detection assembly 1 includes a reflector 2 and a laser power detector 3, and the reflector 2 reflects the laser light emitted by the laser The power is detected on the laser power detector 3 , and the reflector 2 periodically reflects the laser beam of the laser, so that the laser power detector 3 periodically receives the laser light reflected by the reflector 2 .

[0033]The reflective plate 2 has better stability relative to the light-transmitting plate. The reflective plate 2 is arranged in front of the laser emitting light path. The angles between them are equal, so that the beam path can be accurately projected onto the receiving surface of the laser detection component through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com