Preparation method of lubricating oil nano detergent

A technology of detergent and lubricating oil, applied in lubricating compositions, additives, petroleum industry and other directions, can solve the problems of poor extreme pressure and anti-wear performance, poor dispersion performance, etc., and achieve improved lubrication, good stability, and good detergency and dispersion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

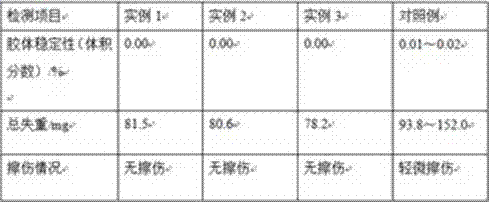

Examples

example 1

[0024] Firstly, the nano-copper powder with an average particle size of 10nm is placed in a fluidized bed reactor, and nitrogen gas with a trimethylaluminum content of 8% is passed into the fluidized bed reactor at a rate of 80mL / min for 30min. Afterwards, feed into the fluidized bed reactor with 20mL / min the nitrogen gas with a moisture content of 3%, after continuing to feed for 5min, discharge, and dry to constant weight to obtain coated nano-copper powder; by mass ratio: 1:80, mix the coated nano-copper powder with a dopamine solution with a mass concentration of 1.8g / L, then continuously feed air into the dopamine solution at a rate of 10mL / min for 40min, and filter to obtain a modified coated nano-copper powder; In parts by weight, 60 parts of petroleum ammonium sulfonate, 150 parts of xylene, 4 parts of calcium oxide, 10 parts of accelerator A, 20 parts of magnesium oxide, 10 parts of water, 8 parts of accelerator B, 20 parts of modified package are taken successively. ...

example 2

[0026]First place the nano-copper powder with an average particle size of 35nm in a fluidized bed reactor, and feed nitrogen with a trimethylaluminum content of 9% into the fluidized bed reactor at a rate of 90mL / min for 45min. After that, feed nitrogen with a moisture content of 4% in the fluidized bed reactor at 40mL / min, continue to feed after 10min, discharge, and dry to constant weight to obtain coated nano-copper powder; 1:90, mix the coated nano-copper powder with a mass concentration of 2.0g / L dopamine solution, then continuously feed air into the dopamine solution at a rate of 15mL / min for 50min, filter to obtain modified coated nano-copper powder; In parts by weight, 70 parts of ammonium petroleum sulfonate, 180 parts of xylene, 6 parts of calcium oxide, 20 parts of accelerator A, 25 parts of magnesium oxide, 15 parts of water, 9 parts of accelerator B, 25 parts of modified package Coated nano-copper powder, 12 parts by mass fraction of 4% sodium silicate solution, i...

example 3

[0028] Firstly, the nano-copper powder with an average particle size of 60nm is placed in a fluidized bed reactor, and nitrogen gas with a trimethylaluminum content of 10% is passed into the fluidized bed reactor at a rate of 100mL / min for 60min. Afterwards, feed nitrogen with a moisture content of 5% into the fluidized-bed reactor at 60mL / min, continue to feed after 15min, discharge, and dry to constant weight to obtain coated nano-copper powder; 1:100, mix the coated nano-copper powder with a mass concentration of 2.2g / L dopamine solution, then continuously feed air into the dopamine solution at a rate of 20mL / min for 60min, and filter to obtain modified coated nano-copper powder; In parts by weight, 80 parts of petroleum ammonium sulfonate, 200 parts of xylene, 8 parts of calcium oxide, 30 parts of accelerator A, 30 parts of magnesium oxide, 20 parts of water, 10 parts of accelerator B, 30 parts of modified package Coated nano-copper powder, 15 parts by mass fraction of 5% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com