Photodiffusion PC material with high flame-retardant performance and preparation method thereof

A light diffusion and high flame retardant technology, applied in the field of high flame retardant light diffusion PC material and its preparation, can solve the problem of not meeting the high flame retardant requirements of thin optical products, affecting light diffusion PC light transmittance and haze, haze and flame retardancy are difficult to guarantee, so as to achieve the effect of easy process operation, low production cost and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

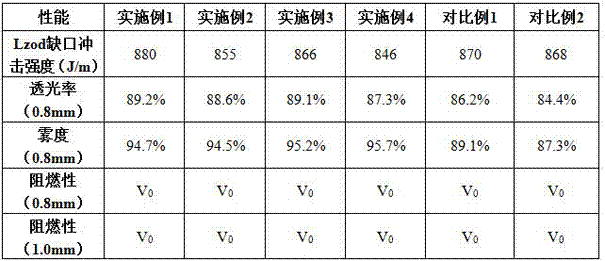

Examples

preparation example Construction

[0077] The preparation method of the above-mentioned high flame-retardant light-diffusing PC material includes the following steps:

[0078] 1) Dry the PC pellets and PC powder separately, the drying temperature is 110~120℃;

[0079] 2) Mix the PC powder and the light diffusing agent uniformly, extrude and granulate to obtain the light diffusing agent masterbatch;

[0080] 3) Fully mix PC pellets, light diffusion agent masterbatch, brominated flame retardant, silicone flame retardant, main antioxidant, auxiliary antioxidant, ultraviolet absorber and lubricant;

[0081] 4) Add the materials of step 3) into a twin-screw extruder, extrude and pelletize, to obtain a high flame-retardant light-diffusing PC material.

[0082] Preferably, in step 2), the mass percentage of the light diffusing agent in the light diffusing agent masterbatch is 3% to 7%.

[0083] Preferably, in step 3), the processing temperature in each zone of the twin-screw extruder is 250-260° C., and the screw speed is 250-30...

Embodiment 1

[0086] 1) Dry PC pellets S-2001R and PC powder at 120°C for 4 hours to make the moisture content of PC resin less than 0.02%;

[0087] 2) Mix 5.7 parts by mass of PC powder and 0.3 parts by mass of light diffusing agent (composed of KMP-590 with a particle size of 2μm and GW-0801T with a particle size of 8μm in a mass ratio of 4:1), and extrude and granulate , To obtain a light diffusing agent masterbatch with a mass percentage of 5% of the light diffusing agent;

[0088] 3) 84.5 parts by mass of PC pellets S-2001R, light diffusion agent masterbatch of step 2), 8 parts by mass of flame retardant BC-58, 0.5 parts by mass of silicone flame retardant FCA117, 0.15 parts by mass Add the main antioxidant 1076, 0.15 parts by mass of the auxiliary antioxidant 168, 0.2 parts by mass of the ultraviolet absorber UV-329 and 0.5 parts by mass of the lubricant PETS to the high mixer, and mix for 1 to 2 minutes;

[0089] 4) Add the materials of step 3) into a twin-screw extruder, extrude and pelle...

Embodiment 2

[0091] 1) Dry PC pellets S-2001R and PC powder at 120°C for 4 hours to make the moisture content of PC resin less than 0.02%;

[0092] 2) Mix 9.7 parts by mass of PC powder and 0.3 parts by mass of light diffusing agent (composed of 30-424 with a particle size of 2μm and GW-0801T with a particle size of 8μm in a mass ratio of 7:3), and extrude and granulate. , To obtain a light diffusing agent masterbatch with a mass percentage of 3% of the light diffusing agent;

[0093] 3) Combine 76.8 parts by mass of PC pellets S-2001R, light diffusing agent masterbatch of step 2), 10 parts by mass of flame retardant BC-58, 2 parts by mass of silicone flame retardant FCA117, 0.1 parts by mass Add the main antioxidant 1076, 0.1 parts by mass of the auxiliary antioxidant 168, 0.3 parts by mass of the ultraviolet absorber UV-329 and 0.7 parts by mass of the lubricant PETS into the high-mixer and mix for 1 to 2 minutes;

[0094] 4) Add the raw materials of step 3) into a twin-screw extruder, extrude...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com