Thermosetting Resin Composition

A resin composition, epoxy resin technology, applied in the direction of epoxy resin glue, adhesive type, electric solid device, etc., can solve the problem of insufficient resistance and other problems, and achieve excellent heat resistance, excellent performance, reliability excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6 and comparative example 2-3、5-6

[0134]The raw materials of the resin composition shown in Table 1 were pulverized and mixed with a super mixer for 5 minutes, and then uniformly mixed / kneaded using a kneader to obtain sealing epoxy resin compositions of the present invention and comparison. This resin composition was pulverized with a mixer, and further formed into a flat plate with a flat plate. Quantification of the residual solvent in the composition was performed using a gas chromatograph (SHIMADZU, GC-2014).

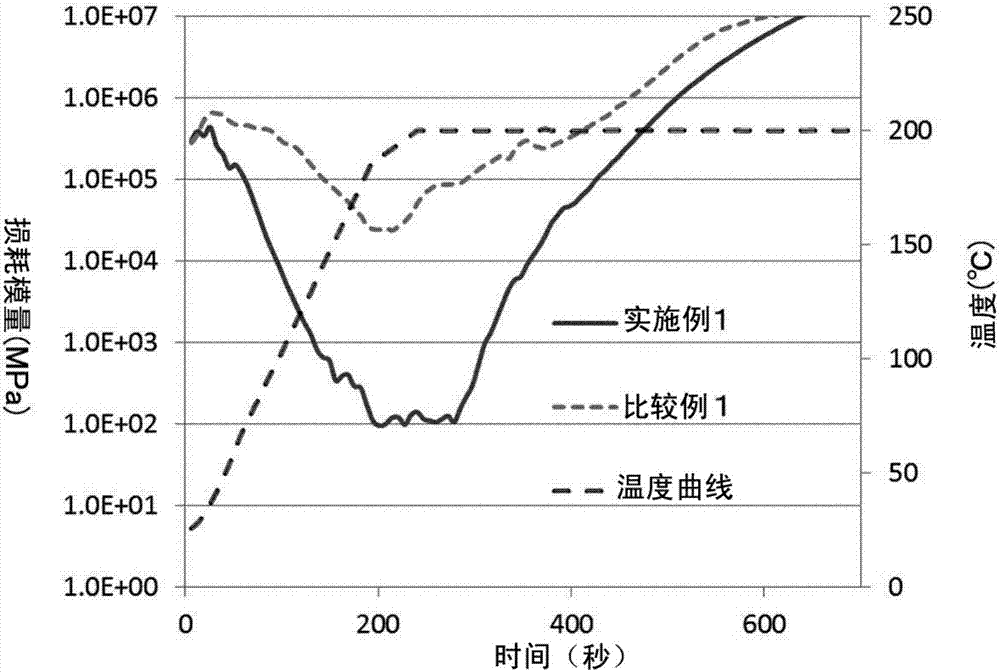

[0135] The measurement of the modulus was performed based on the following method. The resin composition flattened so that it might become 1 cmphi and 2 mm in thickness was measured by the parallel plate method using the rheometer (TA Instruments company make, DHR-2) under the condition of pressure 20 MPa. Under the conditions of a pitch of 2000 μm, a rotating plate diameter of 8 mm, a frequency of 1.0 Hz, and a strain of 0.1%, after stabilizing the temperature of the measuring part to 23 °C, the ...

Embodiment 7、8、 comparative example 7

[0150] In Example 1, Examples 7, 8, and Comparative Example 7 shown in Table 3, a thermal cycle test at 200° C. to -50° C. was carried out instead of the power cycle test in Example 1. The same method as in Example 1 is carried out. Details of the heat cycle test are shown below.

[0151] Using the thermal shock device TSE-11 manufactured by ESPEC Corp., hold the sample at 200°C for 30 minutes and hold it at -50°C for 30 minutes as one cycle, take out the sample after 500 cycles, and check the curing visually Whether the material has cracks or peeling off (Table 4).

[0152] The results are shown in Table 3. In Examples 1, 7, and 8, no cracks were observed after the thermal cycle test, and in Comparative Example 7, cracks were observed after the thermal cycle test. Since the softening point of the epoxy resin in Comparative Example 7 was too low, it is considered that it tends to be defective after the heat cycle test.

[0153] [table 3]

[0154]

[0155] [Table 4]

...

Embodiment 9~12、 comparative example 8

[0158] Example 1, Examples 9 to 12, and Comparative Example 8 shown in Table 5 were operated under the temperature conditions of the thermal cycle test of 180°C to -50°C (Table 6), and the same method as Table 3 was used. method to operate.

[0159] The results are shown in Table 5. In Examples 1, 9-12, no cracks were observed after the thermal cycle test, and in Comparative Example 8, cracks were observed after the thermal cycle test. Since the softening point of the curing agent in Comparative Example 8 was too low, the heat resistance of the cured product was insufficient. In addition, the equivalent weight of the curing agent was too large, so the crosslinking density of the cured product was insufficient. Defects are prone to occur after the test.

[0160] [table 5]

[0161]

[0162] [Table 6]

[0163]

[0164] [Table 7]

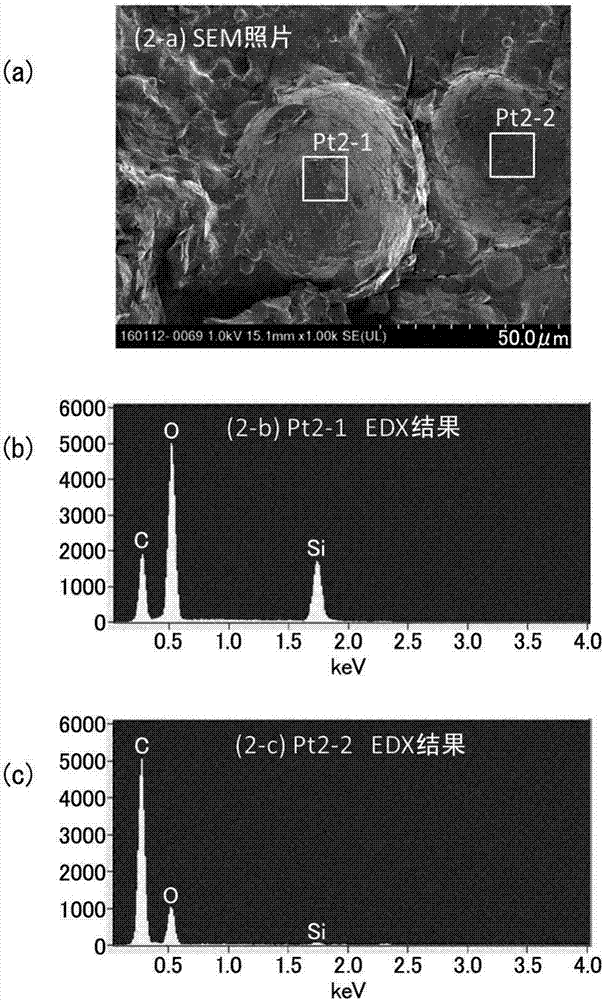

[0165] Measurement site

Pt2-1

Pt2-2

C

37

84

Si

18

1

C / Si

2

-

[0166] The quant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com