Superfine zirconium carbide ceramic fiber and preparation method thereof

A technology of ceramic fiber and zirconium carbide, which is applied in the field of ultrafine zirconium carbide ceramic fiber and its preparation, and achieves the effects of adjustable rheology, convenient operation and maintaining fiber morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) At 25°C, 5.85g of allylphenolic (AN) with an allylation degree of 80%, 50g of yttrium-containing polyzirconium (PNZ-Y), and a molar ratio of yttrium to zirconium of 2 : 25, zirconium element is 11.70g, polyvinylpyrrolidone (PVP) 3.34g is dissolved in ethylene glycol monoethyl ether (EE), stirs until forming brown transparent homogeneous solution, adjusts viscosity to 442mPa s, obtains zirconium carbide ceramic precursor Spinning solution (PNZ-Y-AN-2), wherein the mass ratio of each component Zr:AN:PVP=3.5:1.75:1, the resulting precursor spinning solution placed at 25°C for one month has a viscosity of 463mPa·s.

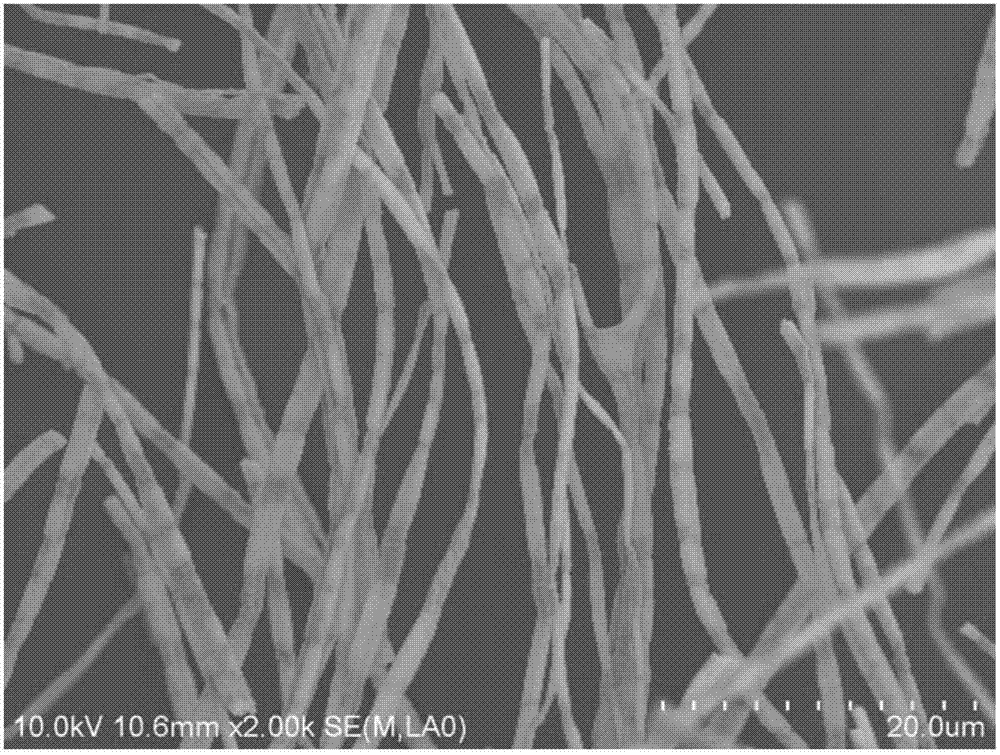

[0048] (2) At a temperature of 25°C and a humidity of 49%, the rotating speed of the centrifuge is 2000r / min, and the aperture of the spinning machine is 0.4mm, and the spinning liquid is thrown out at a high speed from the spinning hole to obtain the precursor fiber and the fiber macro photo as figure 1 As shown, the precursor fiber was placed in a tube ...

Embodiment 2

[0052] (1) At 25°C, 4.68g of allylphenolic (AN) with a degree of allylation of 85%, 50g of yttrium-containing polyzirconium (PNZ-Y), and a molar ratio of yttrium to zirconium of 3 : 100, the zirconium element is 11.70g, polyvinyl acetate (PVAc) 3.90g is dissolved in ethylene glycol monomethyl ether, stirs until forming brown transparent homogeneous solution, adjusts viscosity to 405mPa s, obtains zirconium carbide ceramic precursor spinning Silk liquid (PNZ-Y-AN-2.5), wherein the mass ratio of each component Zr:AN:PVAc=3:1.2:1, the resulting precursor spinning liquid has a viscosity of 430mPa after being placed at 25°C for one month ·s.

[0053] (2) Under the conditions of a temperature of 15°C and a humidity of 49%, the rotating speed of the centrifuge is 3000r / min, and the aperture of the spinning machine is 0.1mm. The body fiber is placed in a tube furnace, the temperature is raised at 1°C / min, and the temperature is kept at 140°C for 0.5h, at 160°C for 1h, at 180°C for 1h...

Embodiment 3

[0056] (1) At 25°C, 3.90g of allylphenolic (AN) with a degree of allylation of 90%, 50g of yttrium-containing polyzirconium (PNZ-Y), and a molar ratio of yttrium to zirconium of 1 :20, the zirconium element is 11.70g, polyvinyl butyral (PVC) 3.90g is dissolved in a mixed solvent of n-propanol and ethylene glycol monoethyl ether, the volume ratio is 1:1, stir until a brown transparent uniform solution is formed, adjust Viscosity to 365mPa·s, obtain zirconium carbide ceramic precursor spinning solution (PNZ-Y-AN-3), wherein the mass ratio of each component Zr:AN:PVP=3:1:1, the precursor spinning that will obtain The viscosity of the silk liquid is 380mPa·s after being placed at 25°C for one month.

[0057] (2) At a temperature of 30°C and a humidity of 49%, the rotating speed of the centrifuge is 8000r / min, and the aperture of the spinning machine is 0.5mm. The body fiber is placed in a tube furnace, the temperature is raised at 1°C / min, and the temperature is kept at 140°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com