Surface treatment method of zirconia implant

A technology of surface treatment and zirconia, which is applied in the fields of dental implants, prostheses, medical science, etc., can solve the problems of not being able to make concave-convex pits, poor shot peening effect, etc., and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

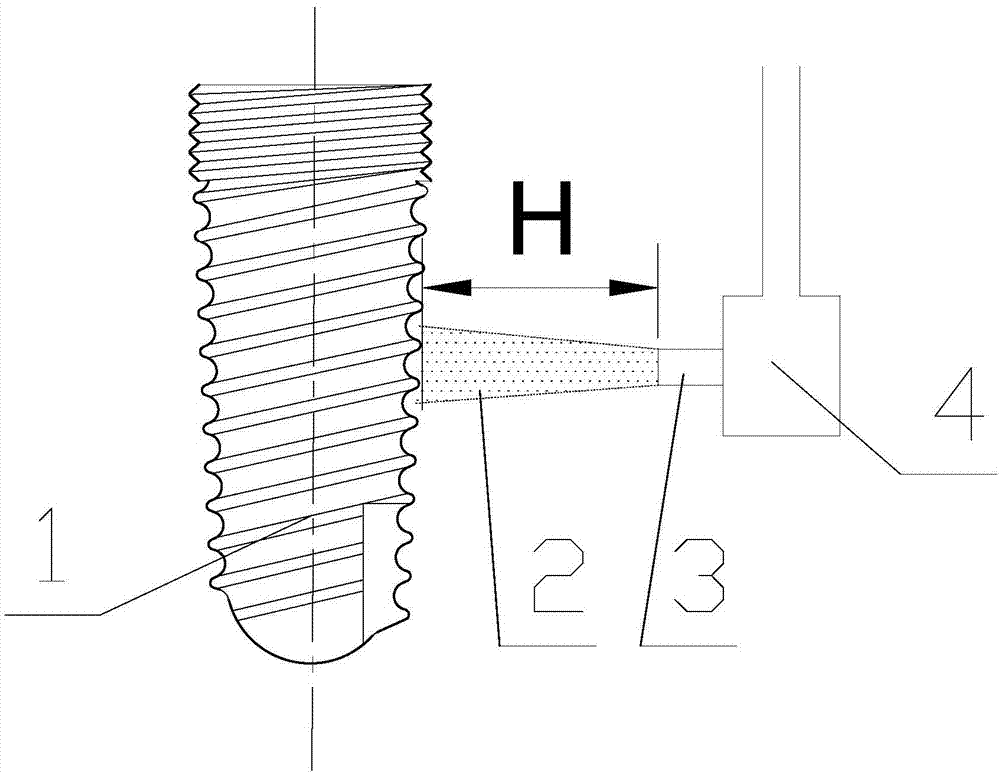

[0018] combine figure 1 As shown, the surface treatment method of the zirconia implant of the present invention is as follows: before the injection-molded zirconia implant blank 1 is dewaxed, the surface of the injection-molded zirconia implant blank 1 is shot peened, so that the surface of the injection-molded zirconia implant blank 1 Concave-convex pits are formed on the surface of the zirconia implant blank 1, then the wax is discharged, and then sintered to form a zirconia implant with a pit-like structure on the surface, and finally the surface is treated with acid etching or other methods to facilitate bone Growth, so that the osseointegration of the gum tissue and the implant is better.

[0019] In order to optimize the technical solution of the present invention, the shot peening treatment is preferably carried out using spherical pellets 2 . Wherein, the shot 2 can be a zirconium ball or an alumina ball. Preferably, the particle size of the spherical pellets 2 is φ0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com