A kind of external jet spray dust cleaning device

A technology of cleaning device and blowing pipe, which is applied to the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles, etc. Good shot peening effect, good peeling effect, easy and fast dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

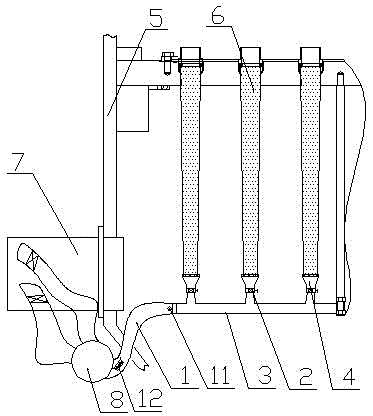

[0020] Such as figure 1 , figure 2 As shown, a kind of external injection spray cleaning device, it includes blowing gas conveying pipe 1, control valve 2 and blowing pipe 3, and described blowing pipe 3 is provided with several nozzles 4, and described nozzles 4 are arranged on dust collector 5 below the filter element 6.

[0021] The blowing gas delivery pipe 1 is connected to the dust-laden gas inlet pipe 7 of the dust collector.

[0022] The blowing gas delivery pipe 1 is provided with a pressure raising device 8 .

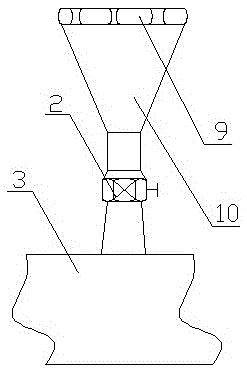

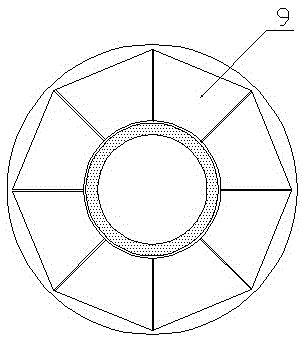

[0023] Several spray head units 9 are arranged at the front end of the nozzle 4, and the spray head units 9 are distributed on the six peripheral sides of the filter core.

[0024] The air outlet end of the spray head unit 9 has a circular arc shape in section.

[0025] A Venturi joint 10 is provided at the connection between the spray head unit 9 and the spray pipe 3 .

[0026] The control valve 2 is an electromagnetic pulse valve.

[0027] The blowing...

Embodiment 2

[0029] Such as image 3 As shown, the difference from Embodiment 1 is that the cross-sectional shape of the air outlet end of the spray head unit 9 is fan-shaped.

Embodiment 3

[0031] The difference from Embodiment 1 or 2 is that: the heating device 12 is a burner.

[0032] The present invention comprises a blowing gas conveying pipe, a control valve and a blowing pipe connected in series. The blowing gas conveying pipe is provided with a pressure raising device, which can realize the blowing and ash removal effect of the high-temperature and high-pressure gas. The blowing pipe is provided with several Nozzle, the nozzle is set under the filter element of the dust collector, cleverly utilizes the structural characteristics of the conical cylinder with a large top and a small bottom of the filter element, the airflow of the ejected gas moves along the outer wall of the filter element, which has a good peeling effect and can Better achieve the purpose of cleaning the dust on the outside of the filter element; further, the blowing gas delivery pipe is connected to the dust-containing gas inlet pipe of the dust collector, and the dust-containing gas can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com