Drawer biofilter adopting composite slow release carbon source as filler

A biological filter, slow-release carbon source technology, applied in biological water/sewage treatment, granular microbial carrier treatment, multi-stage water treatment, etc., can solve problems such as affecting denitrification effect, increasing operating cost, and showing acidity of solution. , to achieve good treatment effect, low operating cost, and the effect of reducing acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

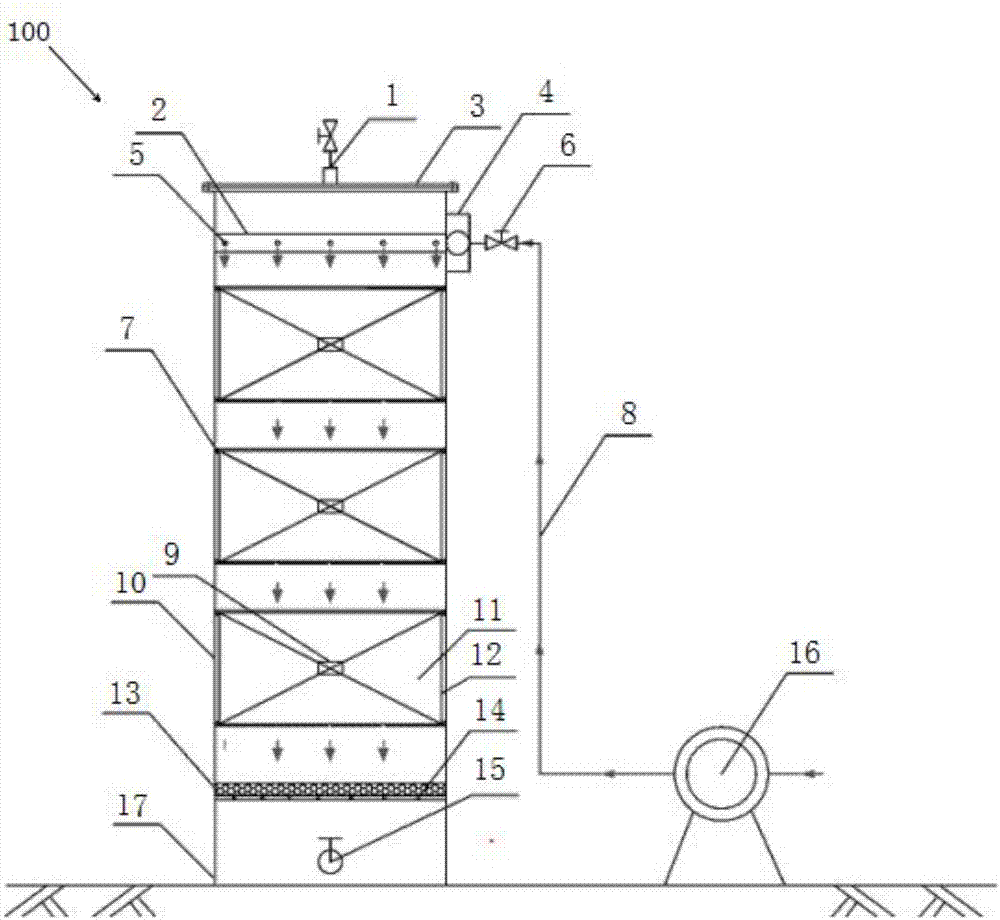

[0018] figure 1 It is a schematic diagram of the overall structure in an embodiment of the present invention.

[0019] Such as figure 1 As shown, a drawer-type biofilter 100 filled with a composite slow-release carbon source in this embodiment includes: an exhaust port 1, a water distribution unit, a drawer unit, a supporting layer, a water outlet 15 and a housing 17 .

[0020] The water distribution unit is used to distribute the water to be treated to the drawer unit.

[0021] The water distribution unit includes: a peristaltic pump 16, which is arranged outside the casing 17, and is used to control the flow rate of the water to be treated; a water inlet conduit 8, which is connected to the peristaltic pump 16, and is used to allow the water to be treated to enter; the water inlet valve 6 is set On the water inlet conduit 8; the shunt pipe 4 is arranged on the top side wall of the housing 17 for shunting the water to be treated; there are multiple water distribution condu...

Embodiment 2

[0038] In the second embodiment, the same structures as those in the first embodiment are given the same symbols, and the same descriptions are omitted.

[0039]Using the same device as in Example 1, the experimental raw water is artificial water distribution, simulating the water quality of the secondary effluent of the urban sewage plant, the effluent water quality is 45-55 mg / l for COD, 6.6-7.4 for pH, DO, NH 3 -N, NO 3 - The mass concentrations of -N and TN are 5.0-7.8, 0.8-1.4, 12.5-14.5, 13.7-17.1 mg / l, respectively. The flow rate is set to 0.02L / min, two drawer units are used, the hydraulic retention time is 24min, and other conditions are the same as in the first embodiment. The experiment adopts intermittent water feeding method.

Embodiment 3

[0041] In the third embodiment, the same structures as those in the first embodiment are assigned the same symbols, and the same descriptions are omitted.

[0042] Using the same device as in Example 1, the raw water is taken to the secondary effluent of an urban sewage plant, and the effluent quality is 50-60 mg / l for COD, 6.5-7.5 for pH, DO, NH 3 -N, NO 3 - The mass concentrations of -N and TN are 5.2-7.5, 0.5-1.5, 12.8-15.8, 13.7-17.7 mg / l, respectively. The flow rate is set to 0.02L / min, three drawer units are used, the hydraulic retention time is 36min, and other conditions are the same as in the first embodiment. The experiment adopts intermittent water feeding method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com