A kind of production process of vehicle urea containing nano-scale catalyst

A technology of urea for vehicles and a production process, which is applied in the chemical industry, can solve problems such as health and safety threats, toxicity, and environmental hazards, and achieve the effects of optimizing continuous purification processes, fast light-off, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

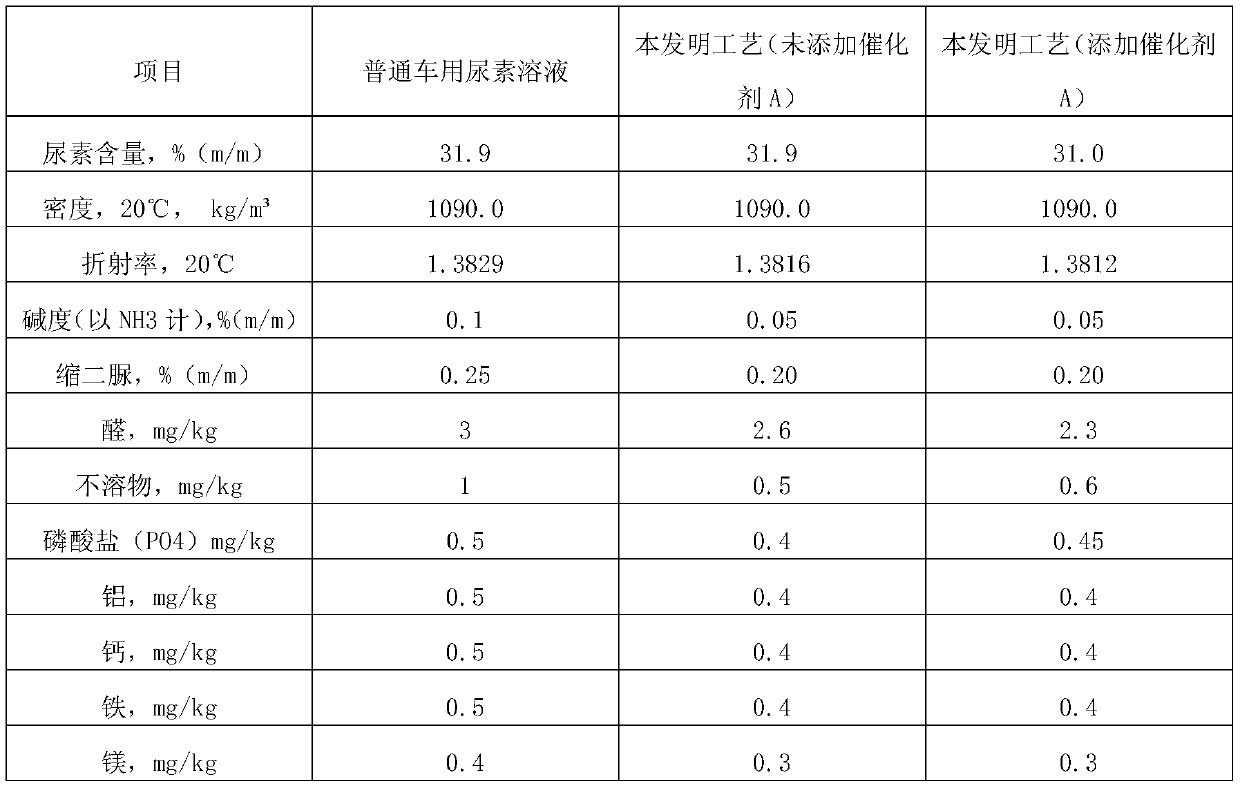

Examples

Embodiment 1

[0019] Embodiment 1, a. prepare catalyst A, get the ammonium metavanadate and oxalic acid of equal mass 50-80g, be dissolved in 1000g deionized water and make solution, add the sodium metaaluminate of 30-40g and stir, in Add 20g of nano-scale WO3 / TiO2 mixture powder during the stirring process, and continue to stir for 2 hours, put it into a temperature-controlled electric furnace at 450 ° C for 1 hour at a high temperature, and then naturally cool to room temperature to obtain Catalyst A.

[0020] b. Catalyst A is stable: Put the prepared catalyst A into the electric furnace again, heat to a high temperature of 650-680°C in a water vapor atmosphere, heat for 30 minutes, and then naturally cool to room temperature.

[0021] c. Preparation of urea solution: at 20-25°C, mix urea and deionized water in parts by weight of 1:2, purify four times to make the insoluble matter less than 2%, add deionized water again to make the concentration of urea solution reach 32%.

[0022] d. Re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com