Water bamboo cleaning and peeling integrated equipment and processing method thereof

The technology of water bamboo and equipment, which is applied in the field of integrated equipment for cleaning and peeling water bamboo and its processing field, can solve the problems of low efficiency, waste of water resources, and increased labor intensity, etc., to improve removal efficiency, increase peeling speed, and realize recycling The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

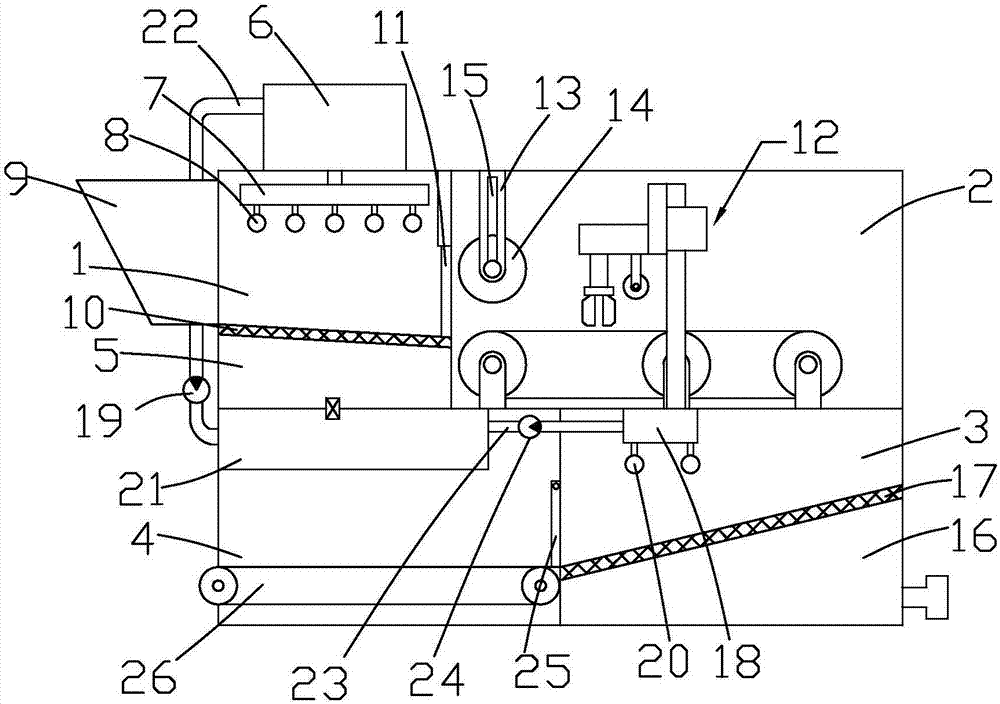

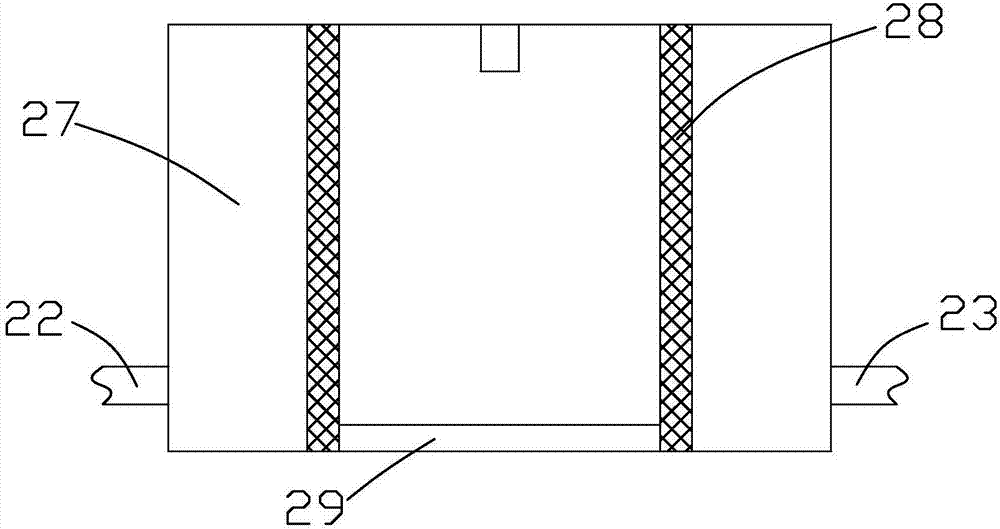

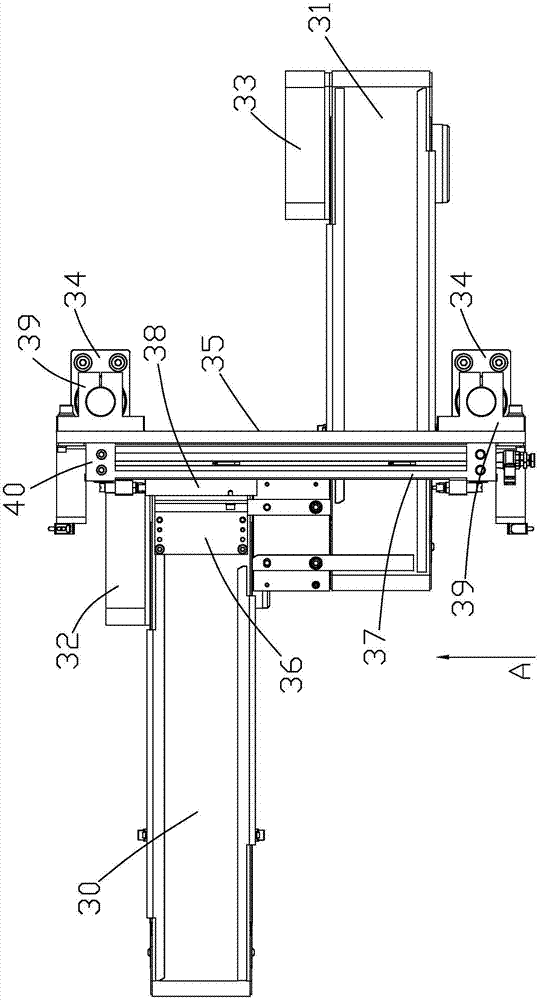

[0045] Such as Figure 1 to Figure 5 As shown, it is a kind of wild rice stem cleaning and peeling integrated equipment of the present invention, comprising a first cleaning chamber 1, a peeling chamber 2, a second cleaning chamber 3 and a discharge chamber 4, and the left side of the first cleaning chamber 1 is provided with an inlet The hopper 9, the first filter plate 10 is arranged obliquely in the first cleaning chamber 1, the first sump 5 is arranged below the first filter plate 10, the first cleaning mechanism is arranged in the first cleaning chamber 1, the first cleaning The mechanism includes a first water storage tank 6, a water delivery pipe 7 and a first spray head 8. The first water storage tank 6 is fixedly connected to the top surface of the first cleaning chamber 1, and the water delivery pipe 7 is horizontally arranged inside the first cleaning chamber 1. Above, the water delivery pipe 7 is fixedly connected to the first water storage tank 6, and the first no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com