Thermoplastic polyurethane foaming body sports field

A technology for thermoplastic polyurethane and sports venues, applied in coatings, buildings, roads, etc., can solve the problems of no restrictions on the use of toxic and hazardous substances or potentially toxic and hazardous substances, and achieve excellent rebound and compression recovery, good elasticity, The effect of suitable mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

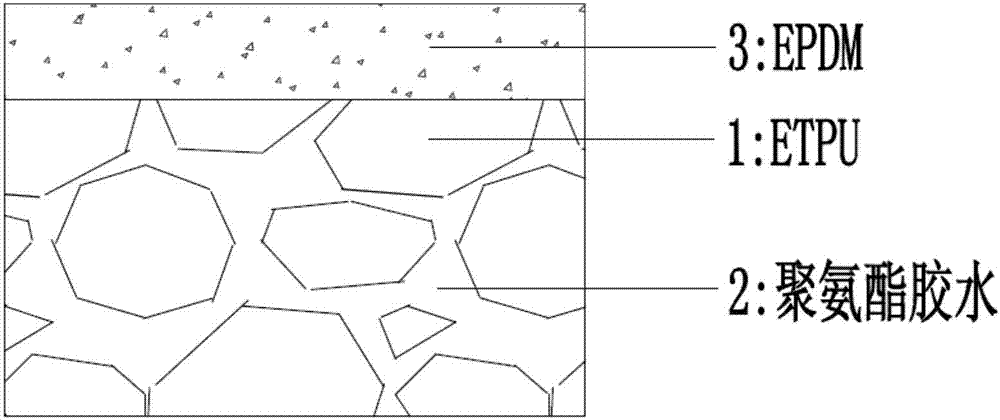

Embodiment 1

[0029] Put the MDI-type thermoplastic polyurethane prepared by 4,4-MDI into a high-pressure reactor, feed carbon dioxide and pressurize, so that the pressure reaches 13Mpa and the temperature is 40°C. After 3 hours, quickly release the pressure and quickly put it into a foaming equipment heated to 100 ° C, and foam for 5 minutes to obtain ETPU. The density of ETPU at this time is 0.18g / cm 3 , the rebound rate is 30%, and the 50-degree compression set is 20%. Mix ETPU and MDI polyurethane adhesive at a mass ratio of 6:1, stir evenly, pour into the paver, pave with a thickness of 10mm, and cure and maintain for 24 hours. Use MDI polyurethane slurry and EPDM particles with an equivalent particle size of 1-3mm to mix evenly, pour it into the spraying machine, tilt the spray gun to 60 degrees to spray in the same direction, wait for 24 hours after spraying, and then spray again in the opposite direction. Spray it to the surface layer with a thickness of 2.5mm, and maintain it for...

Embodiment 2

[0032] Put 2,4-MDI and 4,4-MDI in a mass ratio of 1:1 to form an MDI-type thermoplastic polyurethane as a raw material, put it into a high-pressure reactor, feed carbon dioxide and pressurize, so that the pressure reaches 13Mpa, and the temperature is 40 ℃, at this time the carbon dioxide is in a supercritical state. In this state, the pressure is kept and infiltrated for 3 hours. After the pressure is released quickly, it is quickly put into the foaming equipment heated to 100 ℃, and foamed for 5 minutes to obtain ETPU. The density of ETPU at this time is 0.18g / cm 3 , the rebound rate is 30%, and the 50-degree compression set is 20%. Mix ETPU and MDI polyurethane adhesive at a mass ratio of 6:1, stir evenly, pour into the paver, pave with a thickness of 10mm, and cure and maintain for 24 hours. Use MDI polyurethane slurry and EPDM particles with an equivalent particle size of 1-3mm to mix evenly, pour it into the spraying machine, tilt the spray gun to 60 degrees to spray in...

Embodiment 3

[0035]Put 2,4-MDI and 4,4-MDI in a mass ratio of 1:1.5 to form an MDI-type thermoplastic polyurethane as a raw material, put it into a high-pressure reactor, feed carbon dioxide and pressurize, so that the pressure reaches 13Mpa and the temperature is 40 ℃, at this time the carbon dioxide is in a supercritical state. In this state, the pressure is kept and infiltrated for 3 hours. After the pressure is released quickly, it is quickly put into the foaming equipment heated to 100 ℃, and foamed for 5 minutes to obtain ETPU. The density of ETPU at this time is 0.18g / cm 3 , the rebound rate is 30%, and the 50-degree compression set is 20%. Mix ETPU and MDI polyurethane adhesive at a mass ratio of 6:1, stir evenly, pour into the paver, pave with a thickness of 10mm, and cure and maintain for 24 hours. Use MDI polyurethane slurry and EPDM particles with an equivalent particle size of 1-3mm to mix evenly, pour it into the spraying machine, tilt the spray gun to 60 degrees to spray in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com