High-efficiency solidified water-resistant adhesive

A technology of adhesives and curing agents, applied in the direction of adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of limiting the application of epoxy resin, poor impact resistance, insufficient toughness, etc., and achieve mechanical properties Excellent, good durability, simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

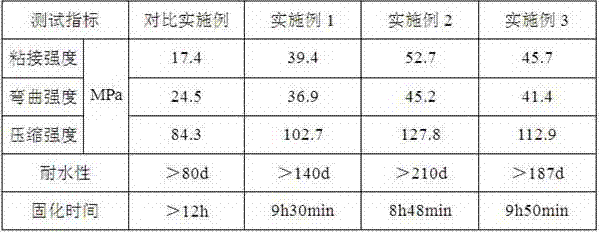

Examples

Embodiment 1

[0014] An efficient curing water-resistant adhesive of this embodiment, expressed in parts by weight, includes 150-270 parts of hydrogenated bisphenol A epoxy resin binder, 20-45 parts of cyanoethylated diethylenetriamine curing agent, ethylene 6-12 parts of glycol diglycidyl ether, 15-30 parts of filler, 9-15 parts of acrylate rubber, 7-20 parts of dimethyl methyl phosphate.

[0015] The preparation method of the present invention, the concrete steps are:

[0016] (1) First prepare raw materials for preparing hydrogenated bisphenol A epoxy resin, expressed in parts by weight, take 6-8 parts of sodium hydroxide, 16-22 parts of epichlorohydrin, 9-13 parts of hydrogenated bisphenol A, methyl isobutyl ketone is added to the reaction kettle according to a certain proportion, and a catalyst is added, and then a constant temperature water bath at 50-60 ° C is stirred; then the reaction is condensed and refluxed for 24 hours;

[0017] (2) After the reaction is over, add deionized wa...

Embodiment 2

[0022] An efficient curing water-resistant adhesive of this embodiment, expressed in parts by weight, is 160 parts of the hydrogenated bisphenol A epoxy resin binder, 25 parts of a cyanoethylated diethylenetriamine curing agent, ethylene glycol diethylene glycol 7 parts of glycidyl ether, 16 parts of filler, 10 parts of acrylate rubber, 10 parts of dimethyl methyl phosphate.

Embodiment 3

[0024] An efficient curing water-resistant adhesive of this embodiment, expressed in parts by weight, includes 220 parts of the hydrogenated bisphenol A epoxy resin binder, 32 parts of cyanoethylated diethylenetriamine curing agent, ethylene glycol diethylene glycol 9 parts of glycidyl ether, 25 parts of filler, 12 parts of acrylate rubber, 15 parts of dimethyl methyl phosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com