Processing technology for forming micro-nano multi-layer composite structure on metal surface

A metal surface and composite structure technology, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of high price, difficulty in industrial application, difficulty in controllability of micro-nano structure, etc., and achieve good ductility and flexibility , Excellent thermal fatigue resistance, not easy to stress concentration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

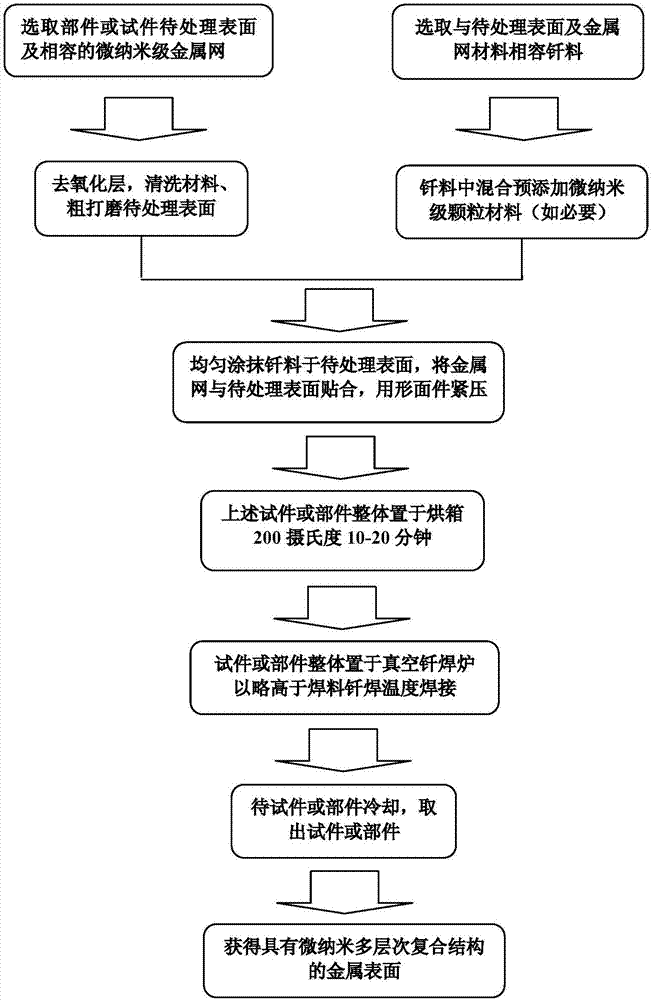

Method used

Image

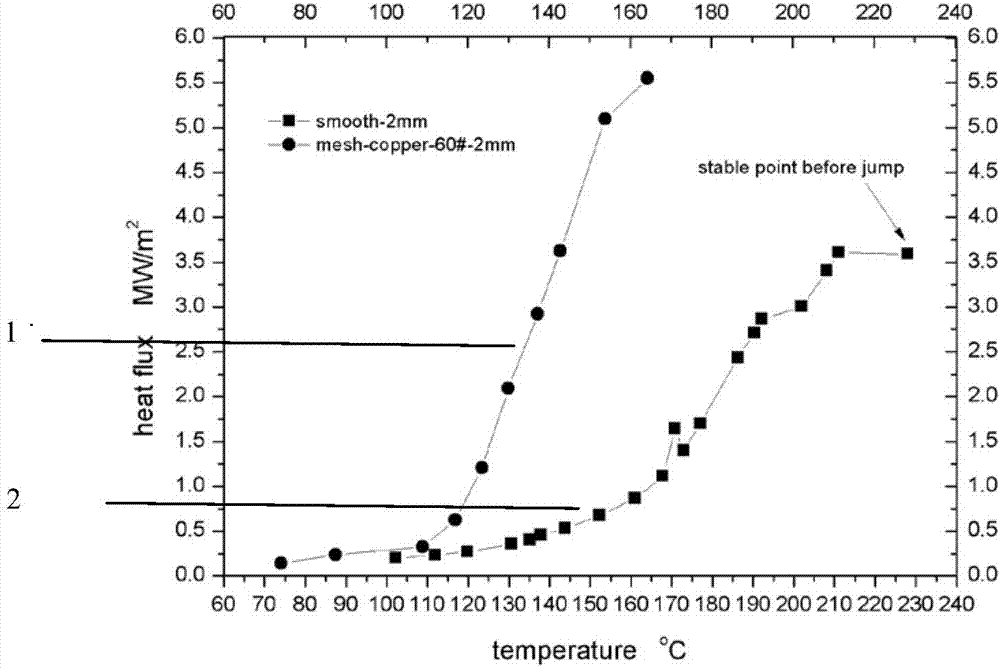

Examples

Embodiment 1

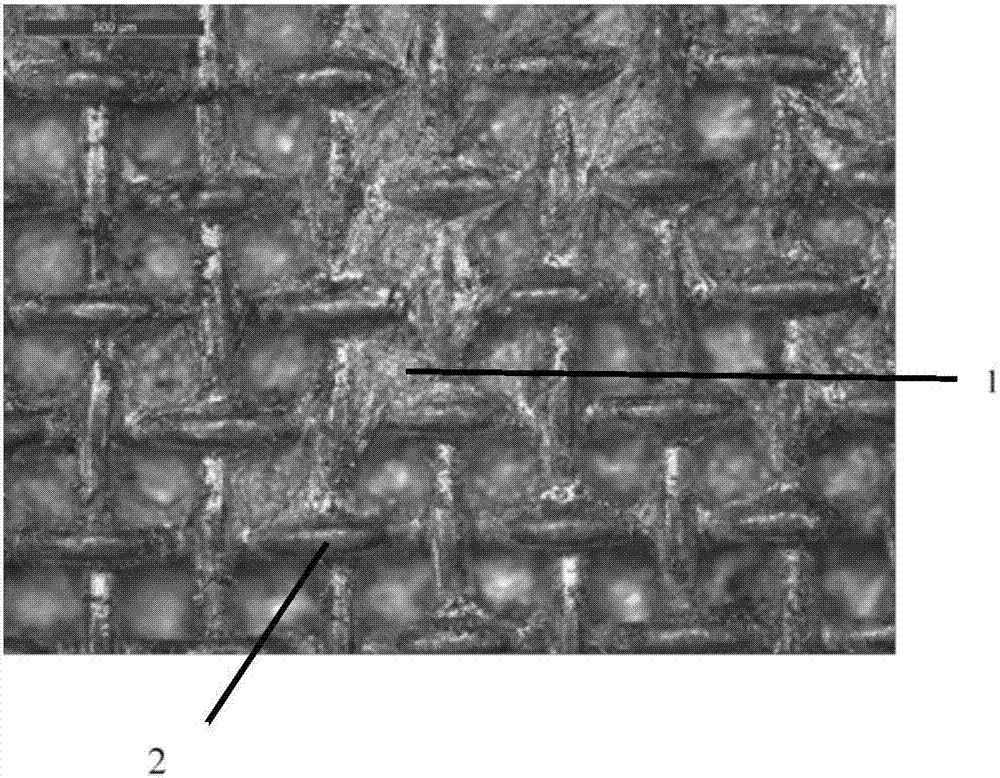

[0034] (1) Select chromium-zirconium copper of 100*10*10mm, of which the surface of 100*10mm is the surface to be treated, and prepare a micron-sized porous copper mesh corresponding to the size of the surface to be treated, that is, 100*10mm, and its wire diameter is 100μm , porosity 250μm, and silver-copper-titanium solder;

[0035] (2) And treat the surface of chrome-zirconium-copper, roughen the surface first, apply dilute hydrochloric acid on the surface to be treated for deoxidation treatment, and then use alcohol and water to clean;

[0036] (3) Cut the copper mesh with the same size as the chrome-zirconium copper surface to be treated, that is, the size is 100*10mm micron-scale pores, so that the copper mesh can be pressed flat and can fit the surface to be treated, and ensure that it can be well attached to the surface to be treated combine;

[0037] (4) Use dilute hydrochloric acid to clean the chrome-zirconium-copper surface to be treated and the copper mesh to rem...

Embodiment 2

[0046] (1) Select chromium-zirconium copper of 100*10*10mm, of which the surface of 100*10mm is the surface to be treated, and prepare a micron-sized porous copper mesh corresponding to the size of the surface to be treated, that is, 100*10mm, and its wire diameter is 60μm , Pore 125μm, and silver-copper-titanium solder;

[0047] (2) And treat the surface of chrome-zirconium-copper, first roughen the surface, apply dilute hydrochloric acid on the surface to be treated for deoxidation treatment, and then use alcohol and water to clean;

[0048] (3) Cut the copper mesh that is consistent with the size of the chrome-zirconium copper surface to be treated, that is, the size is 100*10mm, the wire diameter is 60 μm, and the pores are 125 μm. Good adhesion to the surface to be treated;

[0049] (4) Use dilute hydrochloric acid to clean the chrome-zirconium-copper surface to be treated and the copper mesh to remove the oxide layer, then use alcohol to clean again, and dry;

[0050] ...

Embodiment 3

[0056] (1) Corresponding to the size of the surface to be treated, that is, a micron-scale porous copper mesh with a size of 100*10mm, its wire diameter is 100 μm, the pores are 250 μm, silver-copper-titanium solder, and nano-diamond powder with particles of 100 nm;

[0057] (2) And treat the surface of chrome-zirconium-copper, roughen the surface first, apply dilute hydrochloric acid on the surface to be treated for deoxidation treatment, and then use alcohol and water to clean;

[0058] (3) Cut the copper mesh with the size of the chrome-zirconium copper surface to be treated, that is, the size is 100*10mm, the wire diameter is 100μm, and the pores are 250μm. Good adhesion to the surface to be treated;

[0059] (4) Use dilute hydrochloric acid to clean the chrome-zirconium-copper surface to be treated and the copper mesh to remove the oxide layer, then use alcohol to clean again, and dry;

[0060] (5) the nano-diamond powder of 100nm is mixed with silver-copper-titanium sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com