Laser 3D printing method for metal workpiece and system thereof

A 3D printing and metal workpiece technology, applied in the field of 3D printing, can solve the problem of low density of metal workpieces, and achieve the effect of improving the density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

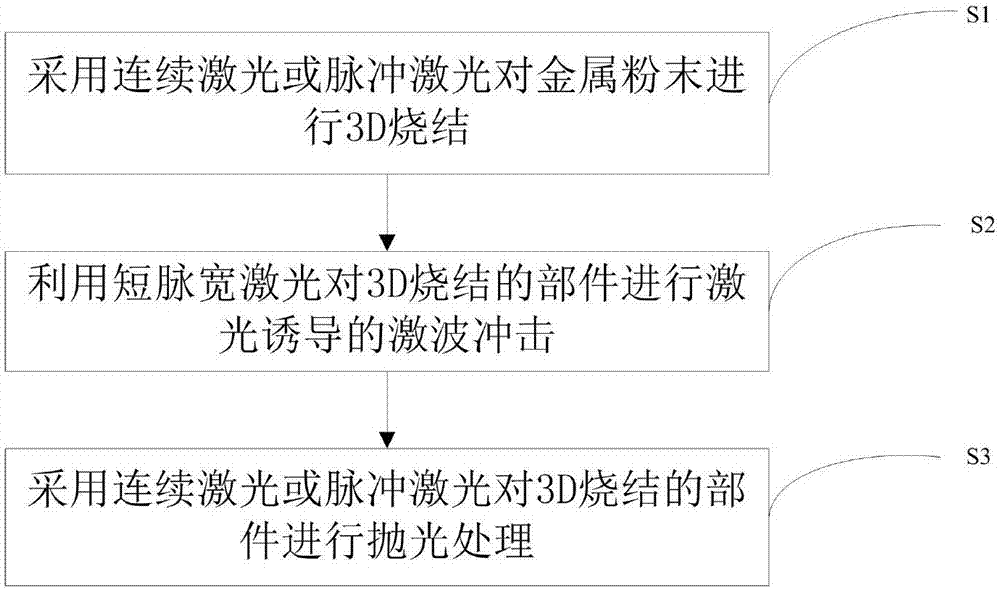

[0021] The present invention will be further elaborated below with reference to the accompanying drawings.

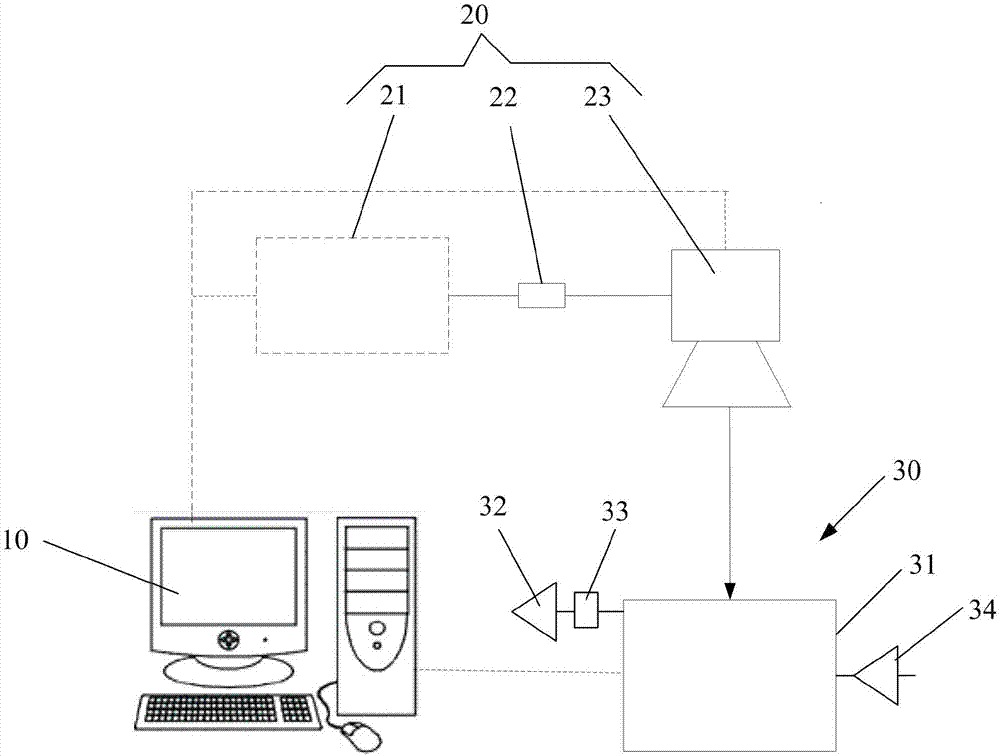

[0022] Please refer to the attached figure 1 , in this example, please refer to figure 1 , the laser 3D printing system for metal workpieces in this embodiment mainly includes an industrial computer 10, a laser scanning device 20 and a metal pool device 30. The industrial computer 10 controls the laser scanning device 20 to perform 3D printing on the metal powder placed in the metal pool device 30 .

[0023] Wherein, the industrial computer 10 is connected with the laser scanning device 20 and the metal pool device 30, and controls the laser scanning device 20 and the metal pool device 30.

[0024] Further, the above-mentioned laser scanning device 20 includes: a laser 21 connected to the industrial computer 10 and adjusting the pulse width according to the control of the industrial computer 10, a beam expander 22 connected to the laser 21, and a beam expander 22 conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com