Waterborne polyurethane emulsion with corrosion resistance and preparation method thereof

A water-based polyurethane and anti-corrosion technology, applied in the field of coatings, can solve the problems of poor water resistance and anti-corrosion performance of the coating film, and no research reports have been seen yet, and achieve the goal of improving anti-corrosion performance, improving anti-corrosion performance, and promoting anti-corrosion performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Add 81.0g of PPG with a molecular weight of 2000 into a 500mL four-necked flask equipped with a stirrer, a thermometer and a condenser, then add 36.0g of IPDI while blowing nitrogen, and react at 80°C for 130min to obtain a terminal group -NCO-based polyurethane prepolymer.

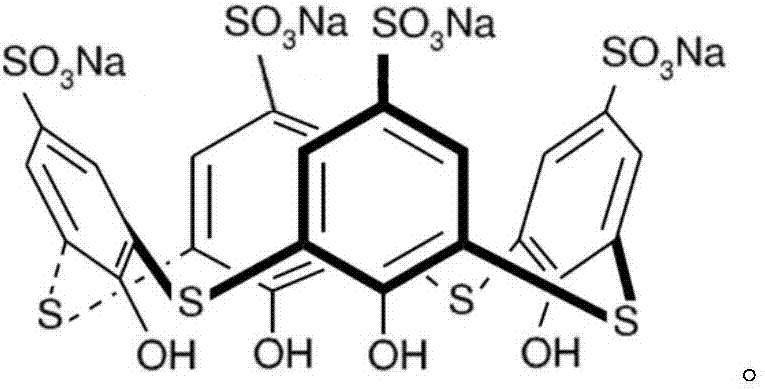

[0034] (2) Cool the prepolymer to 60°C, add 50.0g of acetone to reduce the viscosity of the system, then add a mixed solution of 2.8g of BDO and 10g of acetone, a mixture of 1.3g of DMPA and 10g of acetone, a mixture of 5.1g of TC4AS and 10g of acetone , and reacted at 65°C for 120 minutes to prepare a polyurethane prepolymer containing hydrophilic groups.

[0035] (3) Cool the material obtained in the previous step to 30°C, add 242.1 mL of deionized water with 3.61 g of triethylamine dissolved therein, and carry out neutralization and emulsification for 30 min under a high-speed shear force of 7000 r / min to obtain Aqueous polyurethane emulsion containing acetone.

[0036] (4) Add 2.5 g of et...

Embodiment 2

[0039] (1) Add 38.0g of PCL and 55.0g of PPG with a molecular weight of 2000 into a 500mL four-neck flask equipped with a stirrer, a thermometer and a condenser tube, heat and melt, then add HDI 29.0g while blowing nitrogen, and heat at 80°C The reaction was carried out for 120 minutes to obtain a polyurethane prepolymer whose end group is -NCO group.

[0040] (2) Cool the resulting prepolymer to 55°C, add 68.0g of acetone to reduce the viscosity of the system, then add a mixed solution of 1.4g of BDO and 10g of acetone, add a mixture of 2.3g of DMPA and 10g of acetone, add 4.2g of TC4AS and 10g of acetone The mixture was continued to react at 65°C for 100 min to obtain a polyurethane prepolymer containing hydrophilic groups.

[0041] (3) Cool the material obtained in the previous step to 35°C, add 245.8 mL of deionized water with 3.9 g of triethylamine dissolved therein, and carry out neutralization and emulsification for 20 min under a high-speed shear force with a rotationa...

Embodiment 3

[0045] (1) Add 22.0g of PCDL and 65.0g of PTMG with a molecular weight of 2000 into a 500mL four-neck flask equipped with a stirrer, a thermometer and a condenser, heat and melt, and then add 19.0g of TDI and 13.0g of HDI while blowing nitrogen , and reacted at 75°C for 130min to obtain a polyurethane prepolymer whose end group is -NCO group.

[0046] (2) Cool the prepolymer obtained to 65°C, add 73g of acetone to reduce the viscosity of the system, then add a mixed solution of 3.1g of BDO and 10g of acetone, add a mixture of 3.0g of DMPA and 10g of acetone, add 3.5g of TC4AS and 10g of acetone The mixture was continued to react at 65°C for 90 minutes to obtain a polyurethane prepolymer containing hydrophilic groups.

[0047] (3) Cool the material obtained in the previous step to 40°C, add 258 mL of deionized water dissolved with 4.07 g of triethylamine, and neutralize and emulsify for 20 minutes under a high-speed shear force of 6000 r / min to obtain Aqueous polyurethane emul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com