Preparation method and application method of water-based drilling cutting adsorptive filter material

A drilling cuttings, water-based technology, which is applied in the field of preparing adsorption filter materials based on water-based drilling cuttings, can solve the problems of increasing environmental protection pressure and wasting resources, and achieves the effects of easy cleaning and regeneration, long service life and good chemical stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

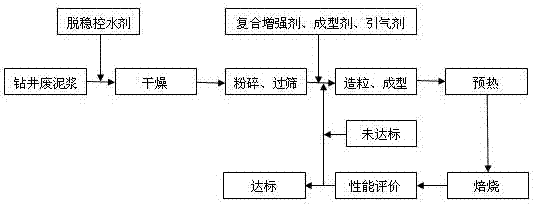

Method used

Image

Examples

Embodiment 1

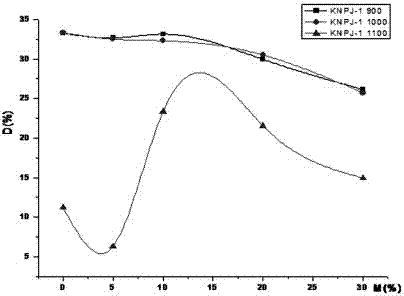

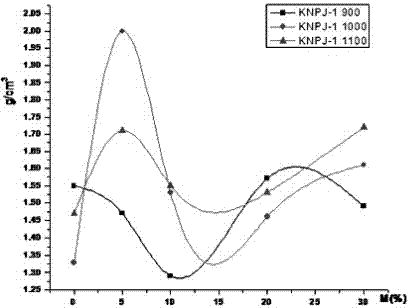

[0029] Mix 100g of dried water-based drill cuttings with 15g of clay and 5g of diatomaceous earth, pulverize with a universal pulverizer and pass through a 20-mesh standard sieve. Then add a small amount of water, stir until the mixture becomes a paste, stop adding distilled water dropwise, and continue stirring for 5 min. Put the uniformly mixed mixture into a mold for molding, and perform a high-temperature roasting step (preheating temperature is 400-600°C, preheating time is 15 minutes, roasting temperature is 1000-1100°C, roasting time is 10min). The water absorption rate of the obtained product is 15%, the filter material density is 1.31 g / cm3, and the porosity is as high as 22%.

Embodiment 2

[0031] Mix 100g of dried water-based drilling cuttings with 6g of starch, 15g of diatomaceous earth, and 2g of sodium carbonate, grind them with a universal grinder, and pass through a 20-mesh standard sieve. Then add a small amount of water, stir until the mixture becomes a paste, stop adding distilled water dropwise, and continue stirring for 5 min. Put the uniformly mixed mixture into a mold for molding, and perform a high-temperature roasting step (preheating temperature is 400-600°C, preheating time is 15 minutes, roasting temperature is 1000-1100°C, roasting time is 10min). The water absorption rate of the obtained product is 21%, the filter material density is 1.28 g / cm3, and the porosity is as high as 23%.

Embodiment 3

[0033] Mix 100g of dried water-based drill cuttings with 5g of clay and 15g of diatomaceous earth, pulverize with a universal pulverizer and pass through a 20-mesh standard sieve. Then add a small amount of water, stir until the mixture becomes a paste, stop adding distilled water dropwise, and continue stirring for 5 min. Put the uniformly mixed mixture into a mold for molding, and perform a high-temperature roasting step (preheating temperature is 400-600°C, preheating time is 15 minutes, roasting temperature is 1000-1100°C, roasting time is 10min). The water absorption rate of the obtained product is 18%, the filter material density is 1.26 g / cm3, and the porosity is as high as 22%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com