Temperature-controlled gas-liquid horizontal reactor with special distributor

A horizontal reactor and distributor technology, applied in the field of reactors, can solve problems such as uneven distribution of heat transfer components, unfavorable reaction stability, and influence on reaction conversion rate, so as to save energy consumption of the system, keep the temperature constant and uniform, The effect of small pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

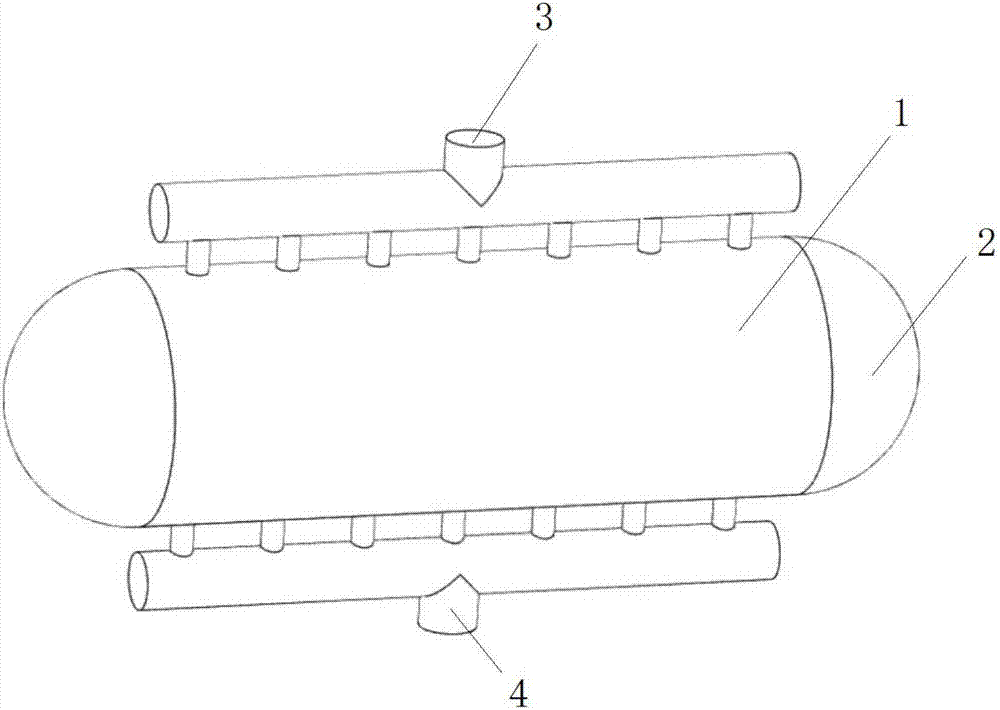

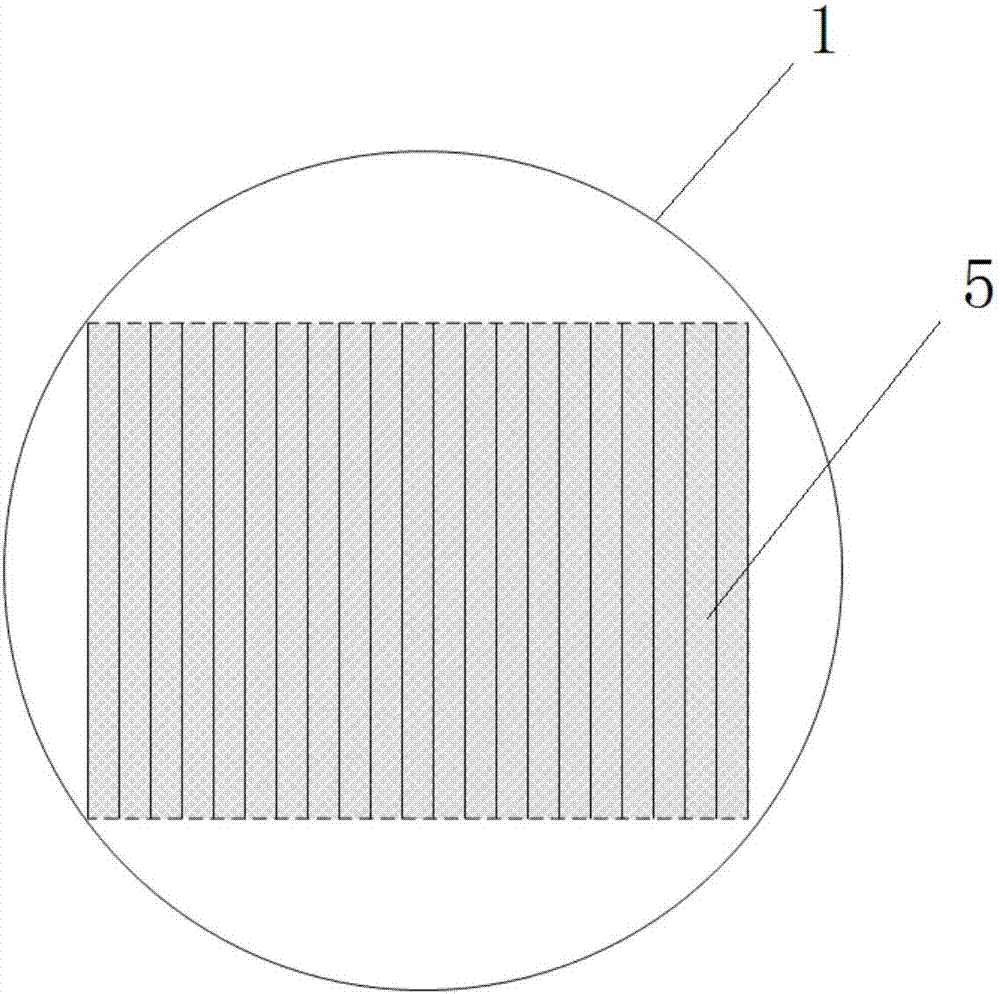

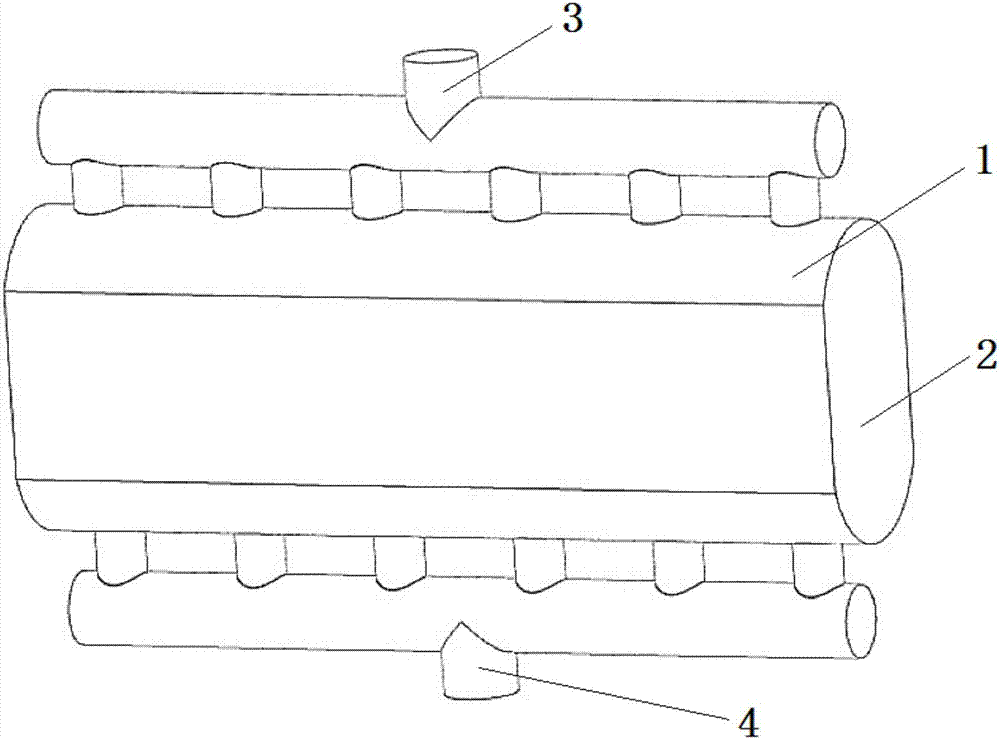

[0051] Synthesis of dimethyl oxalate by carbonylation coupling reaction adopts the large-scale temperature-controlled horizontal reactor of the present invention, such as figure 2 , Figure 5 , in parallel form, the spacing between plates is 24-30mm, which can meet the heat exchange requirements, the catalyst bed height is 2-4m, and the pressure drop meets the requirements. In the case of meeting the national road transportation standards, the reactor processing scale can be increased by 2 ~5 times.

Embodiment 2

[0053] For synthesis gas to methanol, using figure 1 and Figure 5 Parallel circular structure, filled with CuO-ZnO-Al2O3 catalyst 90m 3 , followed by a series of air-cooled reactors, the processing capacity can reach an annual production capacity of 1.5 million tons of methanol. Under operating conditions: reaction pressure 8.8Mpa, reaction material inlet temperature 240°C, by-product 250°C, 4MPa steam 400t / h, the catalyst in the reactor is evenly loaded, the pressure field is evenly distributed, the pressure drop is less than 300KPa, and the distance between the heat exchange plates and the bundles is 30-40mm, the temperature of the hot spot of the reaction can be controlled within 270°C, and the catalyst maintains a high activity without side reactions. less, the export methanol mole fraction can reach 12%, which meets the process requirements and has significant benefits.

Embodiment 3

[0055] like Image 6 As shown, the heat exchange plate bundle is divided into multiple sections in the horizontal direction, and the number, spacing, and shape of the heat exchange plate bundles in each section are independent and adjustable, and are adjusted according to the difference in the amount of heat released by the reaction in different stages of the reactor. The required heat exchange area; different sections can be loaded with different catalysts to realize multiple reactions in series in a single reactor. The reactor is applied to the synthesis of ethanol from dimethyl ether. The reactor is divided into two sections in series. The first section is filled with a catalyst for the carbonylation of dimethyl ether to produce methyl acetate, and the second section is filled with a catalyst for the hydrogenation of methyl acetate to produce ethanol. Catalyst, high selectivity ethanol can be prepared through these two reactions, the reaction temperature and pressure of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com