Novel rotary spraying stirrer for preventing oil sludge deposition of crude oil storage tank

A crude oil storage tank and rotary jet technology is applied in the field of devices used for preventing sludge deposition in crude oil storage tanks, which can solve the problems of accelerated rotation speed, large fluid energy loss, low transmission efficiency, etc., and achieves stable speed control, easy processing and manufacturing, The effect of small energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

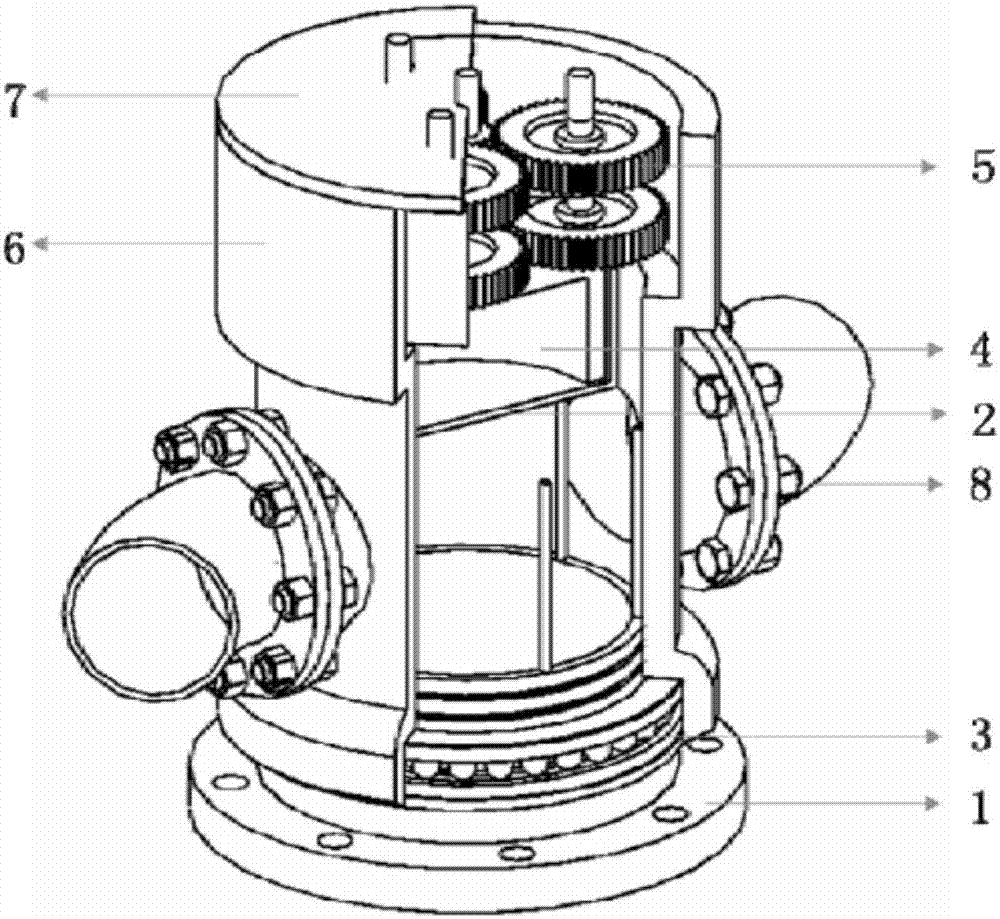

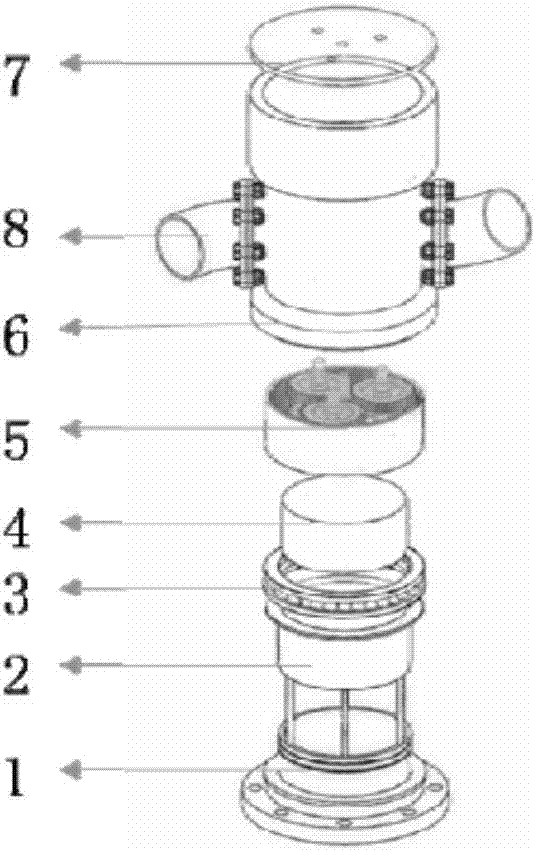

[0019] The novel rotary jet agitator used for preventing oil sludge deposition in crude oil storage tank of the present invention, its preferred specific embodiment is:

[0020] Including the fixed base, the outer cylinder of the hydraulic damper, the thrust bearing, the inner cylinder of the hydraulic damper, the planetary gear mechanism, the rotating shell, the top cover, and the nozzle;

[0021] The outer cylinder of the hydraulic damper and the inner cylinder of the hydraulic damper together form a hydraulic damper, the lower end of the hydraulic damper is connected to the fixed base, and the input shaft at the upper end is connected to the output shaft of the planetary gear mechanism;

[0022] The fixed base is connected with the outer cylinder of the hydraulic damper through supporting ribs;

[0023] The nozzle is connected to the rotating shell through a flange, and the nozzle is an arc-shaped curved nozzle arranged concentrically or a straight nozzle arranged eccentric...

specific Embodiment

[0032] Such as Figure 1a to Figure 5b As shown, the rotary jet agitator and the storage tank, oil pipeline, valves and oil pumps form a rotary jet agitator system.

[0033] The oil pump pumps the crude oil from the bottom of the storage tank and transports it through the oil pipeline to the bottom inlet of the rotary ejector installed on the inner wall of the storage tank or at the center of the storage tank. The rotary jet agitator and the oil pipeline are connected by an 8-inch standard flange. If necessary, a reinforcing rib is set between the oil pipeline and the ground at the connection between the two to prevent the rotary jet agitator from shaking when it is working. The structure of the rotary jet agitator mainly includes a fixed base 1, a hydraulic damper outer cylinder 2, a thrust bearing 3, a hydraulic damper inner cylinder 4, a planetary gear mechanism 5, a rotating housing 6, a top cover 7, and a nozzle 8; The fixed base 1, the bottom of the hydraulic damper out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com