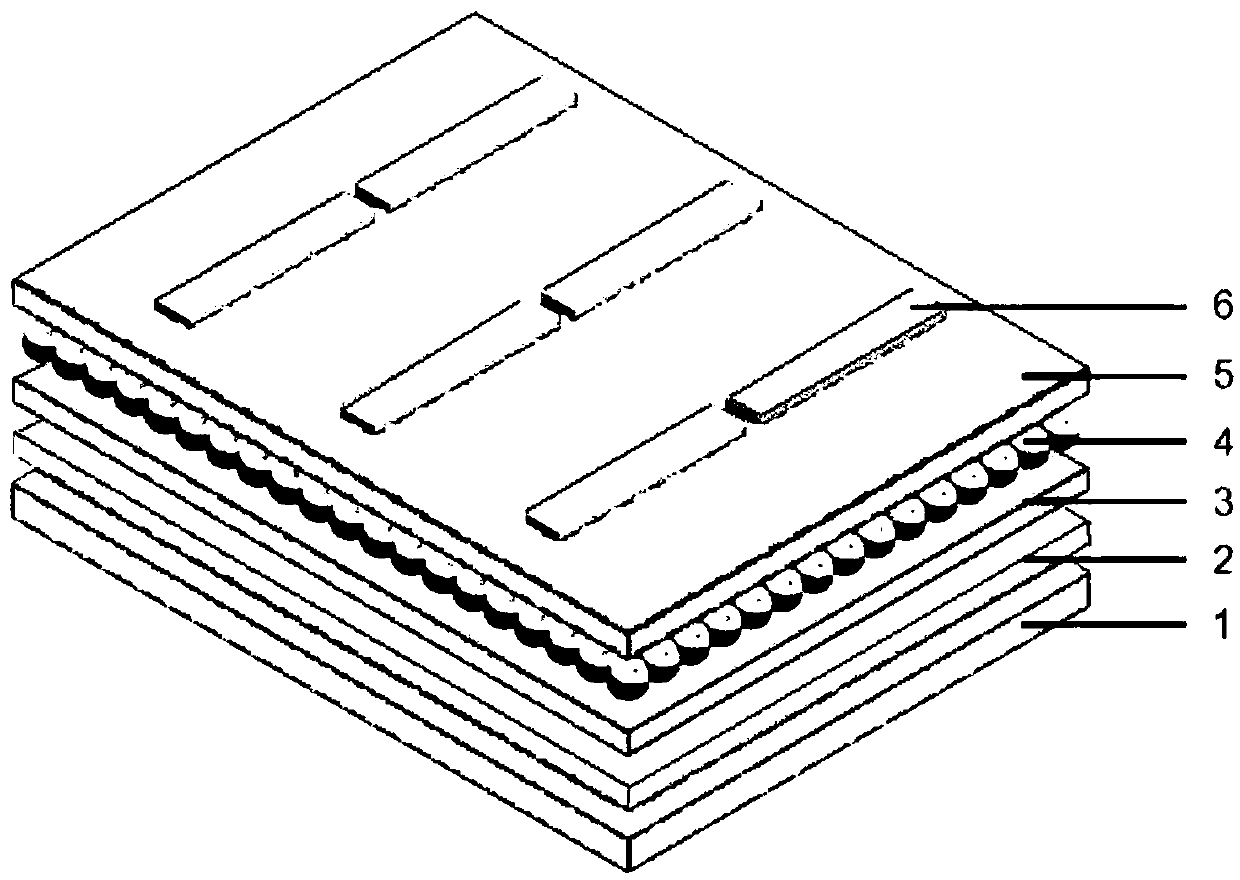

nio composite film, quantum dot light-emitting device and their preparation and application

A technology for quantum dot light-emitting and composite material thin films, which is applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of short lifespan of quantum dot light-emitting devices, improve performance and stability, accelerate migration speed, and easy to obtain. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In the present embodiment, a kind of preparation method of Cu:NiO / NiO composite film comprises the following steps:

[0034] a. Mix 0.97mmol of nickel acetate tetrahydrate and 0.03mmol of copper acetate monohydrate and dissolve them in 10ml of absolute ethanol, add 60.4μl of ethanolamine dropwise while stirring as a stabilizer, stir at 70°C for 4h, and then Stir at room temperature for 8h to obtain Cu:NiO solution for subsequent use;

[0035] b. Dissolve 1 mmol of nickel acetate tetrahydrate in 10 ml of absolute ethanol, add dropwise 60.4 μl of ethanolamine as a stabilizer while stirring, stir at 70°C for 4 hours, and then stir at room temperature for 8 hours to obtain a NiO solution for later use;

[0036] c. draw the Cu:NiO solution prepared in the step a of 120 μl on the ITO substrate with a pipette gun, spin-coat 50s with a speed of 4000rpm, prepare Cu:NiO coating liquid film on the ITO substrate, The Cu:NiO coating liquid film was dried and solidified at 400°C in ...

Embodiment 2

[0040] This embodiment is basically the same as Embodiment 1, especially in that:

[0041] In the present embodiment, a kind of preparation method of Li:NiO / NiO composite film comprises the following steps:

[0042] a. Mix 0.97mmol of nickel acetate tetrahydrate and 0.03mmol of lithium chloride and dissolve in 10ml of absolute ethanol, add dropwise 60.4μl of ethanolamine as a stabilizer while stirring, stir at 70°C for 4h, then at room temperature Stir 8h, obtain Li:NiO solution, standby;

[0043] b. This step is the same as in Embodiment 1;

[0044] c. draw the Li:NiO solution prepared in the step a of 120 μl on the ITO substrate with a pipette gun, spin-coat 50s with a speed of 4000rpm, prepare Li:NiO coating liquid film on the ITO substrate, Dry and solidify the Li:NiO coated liquid film in air at 400°C, and then perform an annealing treatment for 20 minutes to obtain a Li:NiO cured film. After the Li:NiO cured film is cooled to room temperature, O 3 -Plasma treatment fo...

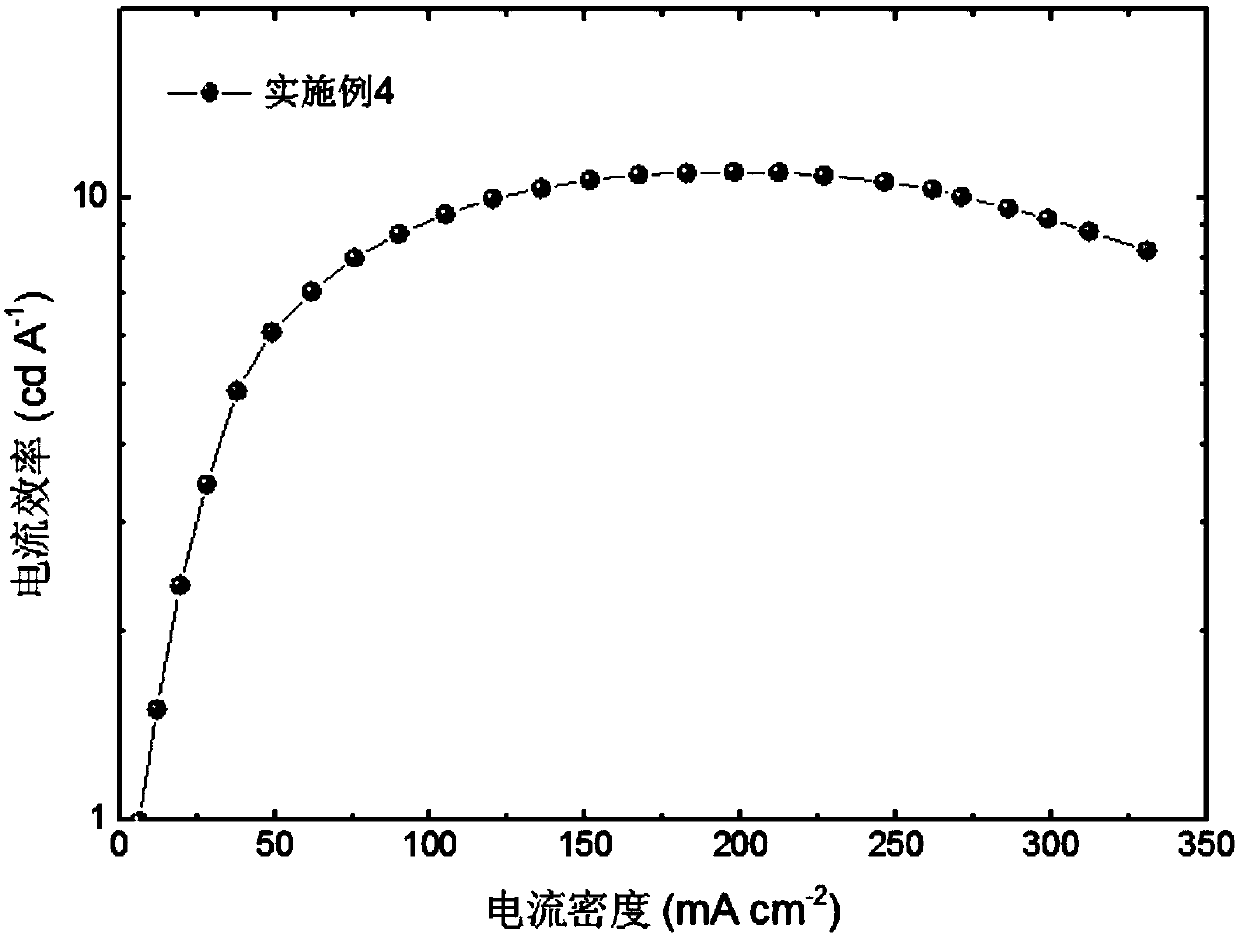

Embodiment 3

[0048] This embodiment is basically the same as the previous embodiment, and the special features are:

[0049] In the present embodiment, a kind of preparation method of Mg:NiO / NiO composite thin film comprises the following steps:

[0050] a. Mix 0.97mmol of nickel acetate tetrahydrate and 0.03mmol of magnesium acetate tetrahydrate and dissolve in 10ml of absolute ethanol, add dropwise 60.4μl of ethanolamine as a stabilizer while stirring, stir at 70°C for 4h, and then Stir at room temperature for 8h to obtain Mg:NiO solution for subsequent use;

[0051] b. This step is the same as in Embodiment 1;

[0052] c. draw the Mg:NiO solution prepared in the step a of 120 μl on the ITO substrate with a pipette gun, spin-coat 60s with a speed of 4000rpm, prepare Mg:NiO coating liquid film on the ITO substrate, The Mg:NiO coating liquid film was dried and solidified at 400°C in air, and then annealed for 20 minutes to obtain a Mg:NiO cured film. After the Mg:NiO cured film was coole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com