Anti-aging cable sheath material and preparation method thereof

A cable sheath and anti-aging technology, applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problem of cable sheath insulation, tensile strength and mechanical properties deterioration, affecting cable performance, and chemical stability Poor resistance and other problems, to achieve the effect of improving anti-aging performance, improving mechanical properties, and excellent aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

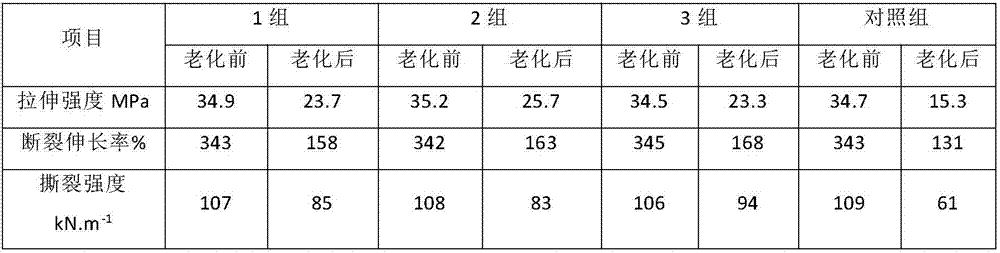

Examples

Embodiment 1

[0026] An anti-aging cable sheath material provided in this embodiment, the anti-aging cable sheath material includes the following raw materials in parts by weight: 64 parts of modified polyurethane resin, 13 parts of chlorinated polyethylene, cis-butene 22 parts of dibutyl diacid, 12 parts of organic nano-montmorillonite, 5 parts of phthalocyanine blue, 2 parts of chlorinated paraffin, 4 parts of anti-aging agent, 0.6 parts of coupling agent, 3.4 parts of ultraviolet absorber, 1.6 parts of plasticizer Part; Wherein, the modification method of described modified polyurethane resin is specifically as follows:

[0027] (1), the anionic polyurethane with sulfonic acid group in the side chain, the acetone solution with a mass concentration of 11% and the hydrochloric acid solution with a mass concentration of 9% are added in the reactor, the anionic polyurethane, acetone solution and hydrochloric acid solution The volume ratio of the amount used is 2:65:0.4, and it is heated. Whe...

Embodiment 2

[0041] An anti-aging cable sheath material provided in this embodiment, the anti-aging cable sheath material includes the following raw materials in parts by weight: 52 parts of modified polyurethane resin, 22 parts of chlorinated polyethylene, cis-butene 7 parts of dibutyl diacid, 19 parts of organic nano-montmorillonite, 2 parts of phthalocyanine blue, 5 parts of chlorinated paraffin, 1 part of anti-aging agent, 2.8 parts of coupling agent, 1.3 parts of ultraviolet absorber, 2.9 parts of plasticizer Part; Wherein, the modification method of described modified polyurethane resin is specifically as follows:

[0042] (1), the anionic polyurethane with sulfonic acid group in the side chain, the acetone solution with a mass concentration of 11% and the hydrochloric acid solution with a mass concentration of 9% are added in the reactor, the anionic polyurethane, acetone solution and hydrochloric acid solution The volume ratio of the amount used is 2:65:0.4, and it is heated. When ...

Embodiment 3

[0056] An anti-aging cable sheath material provided in this embodiment, the anti-aging cable sheath material includes the following raw materials in parts by weight: 57 parts of modified polyurethane resin, 19 parts of chlorinated polyethylene, cisbutene 11 parts of dibutyl diacid, 17 parts of organic nano-montmorillonite, 3 parts of phthalocyanine blue, 4 parts of chlorinated paraffin, 3 parts of anti-aging agent, 1.3 parts of coupling agent, 2.4 parts of ultraviolet absorber, 2.3 parts of plasticizer Part; Wherein, the modification method of described modified polyurethane resin is specifically as follows:

[0057] (1), the anionic polyurethane with sulfonic acid group in the side chain, the acetone solution with a mass concentration of 11% and the hydrochloric acid solution with a mass concentration of 9% are added in the reactor, the anionic polyurethane, acetone solution and hydrochloric acid solution The volume ratio of the amount used is 2:65:0.4, and it is heated. When...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com