Thin-walled antistatic halogen-free flame retardant PC/ABS (polycarbonate/acrylonitrile-butadiene-styrene) composition and preparation method thereof

An anti-static and composition technology, applied in the field of PC/ABS alloy materials, can solve the anti-static effect and flame retardancy, it is difficult to achieve uniform thin-walled materials, can not meet the forming process of thin-walled materials, and fails to achieve high fluidity and other problems, to achieve the effect of good fluidity and thin-wall flame retardancy, good thin-wall flame retardant performance and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

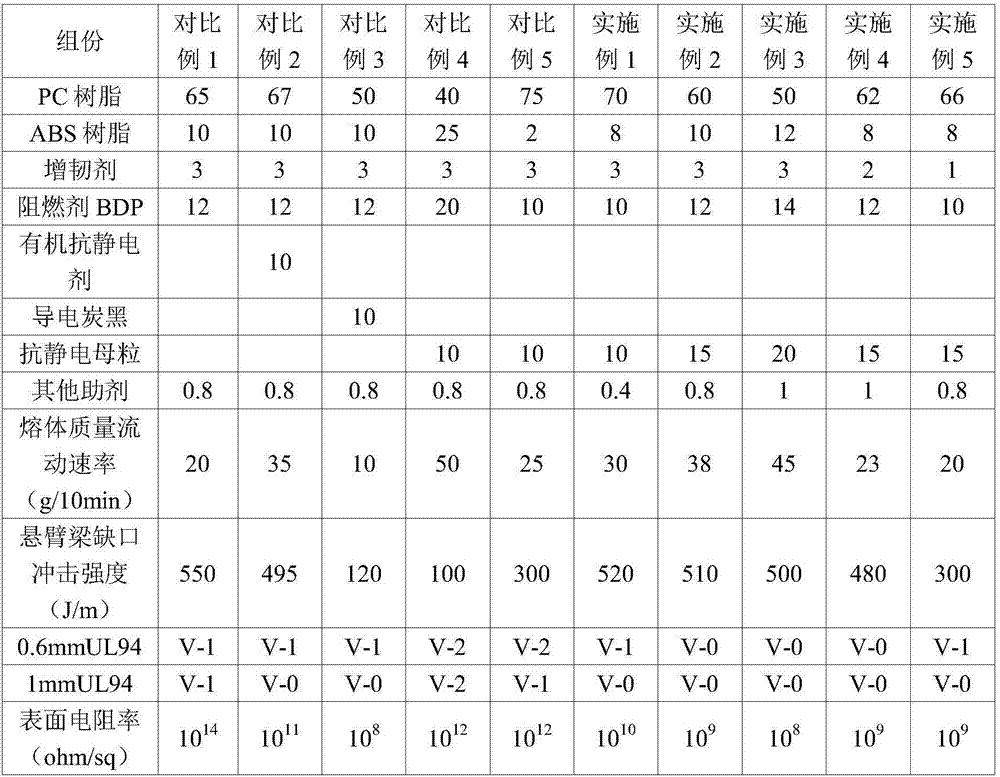

[0042] According to the ratio in Table 1, add PC resin, ABS resin, toughening agent, flame retardant, antistatic masterbatch, and other additives according to parts by weight, and mix them in a high-speed mixer for 5 minutes, then add them to the hopper of a twin-screw extruder , extruded by extruder, water-cooled, air-dried and granulated. The extruder temperature is controlled at 220-240°C, the screw speed is 300-500rpm, and the screw length-to-diameter ratio is 40:1.

[0043] The prepared composition particles were used in a constant temperature blast drying oven; at 90°C for 2 hours, the injection molding machine injected ASTM specimens and 15mm*15mm color plates for flame retardancy, antistatic and Izod notched impact strength tests.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com