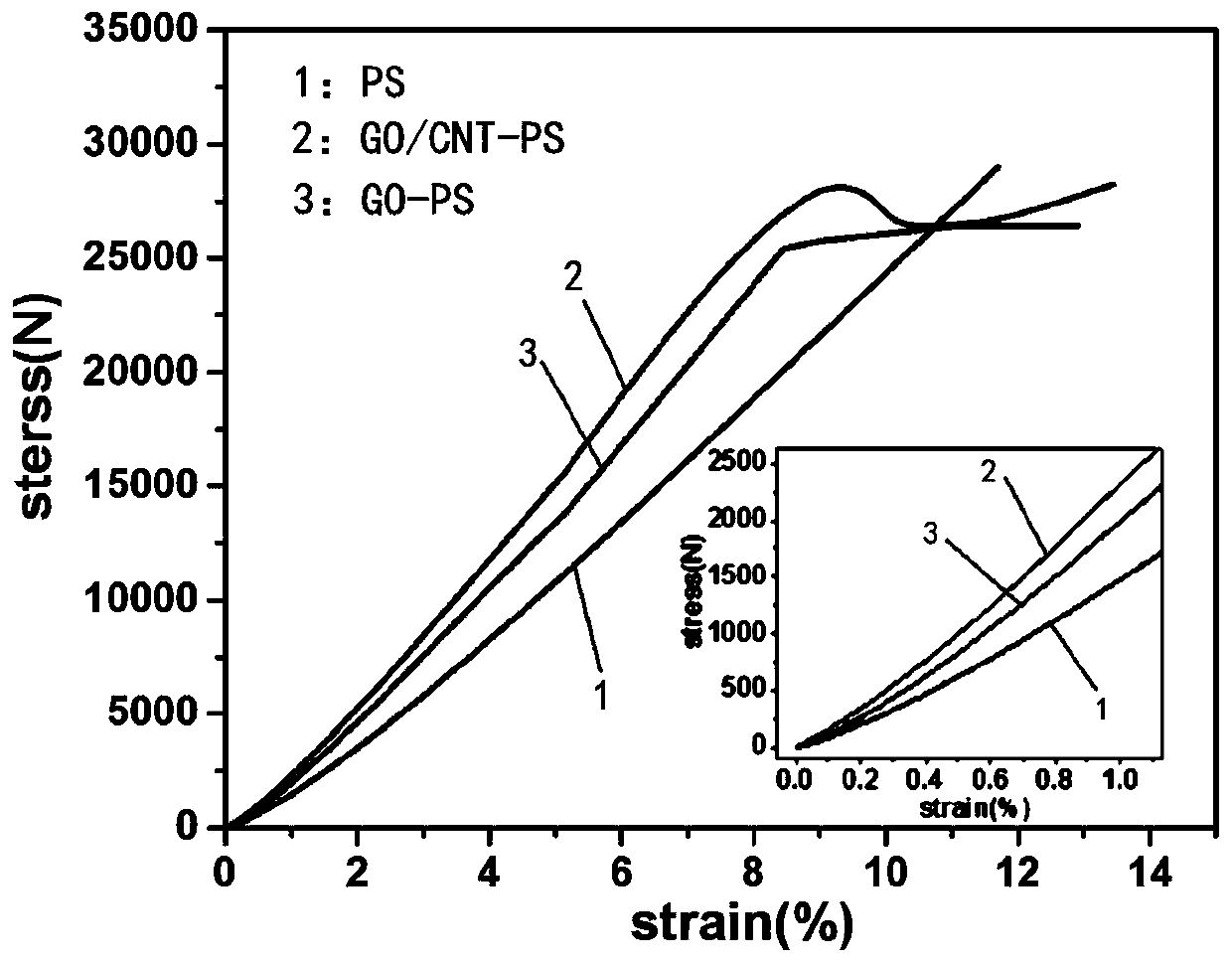

A kind of high-performance carbon nanotube/graphene oxide aerogel/polystyrene composite material and preparation method thereof

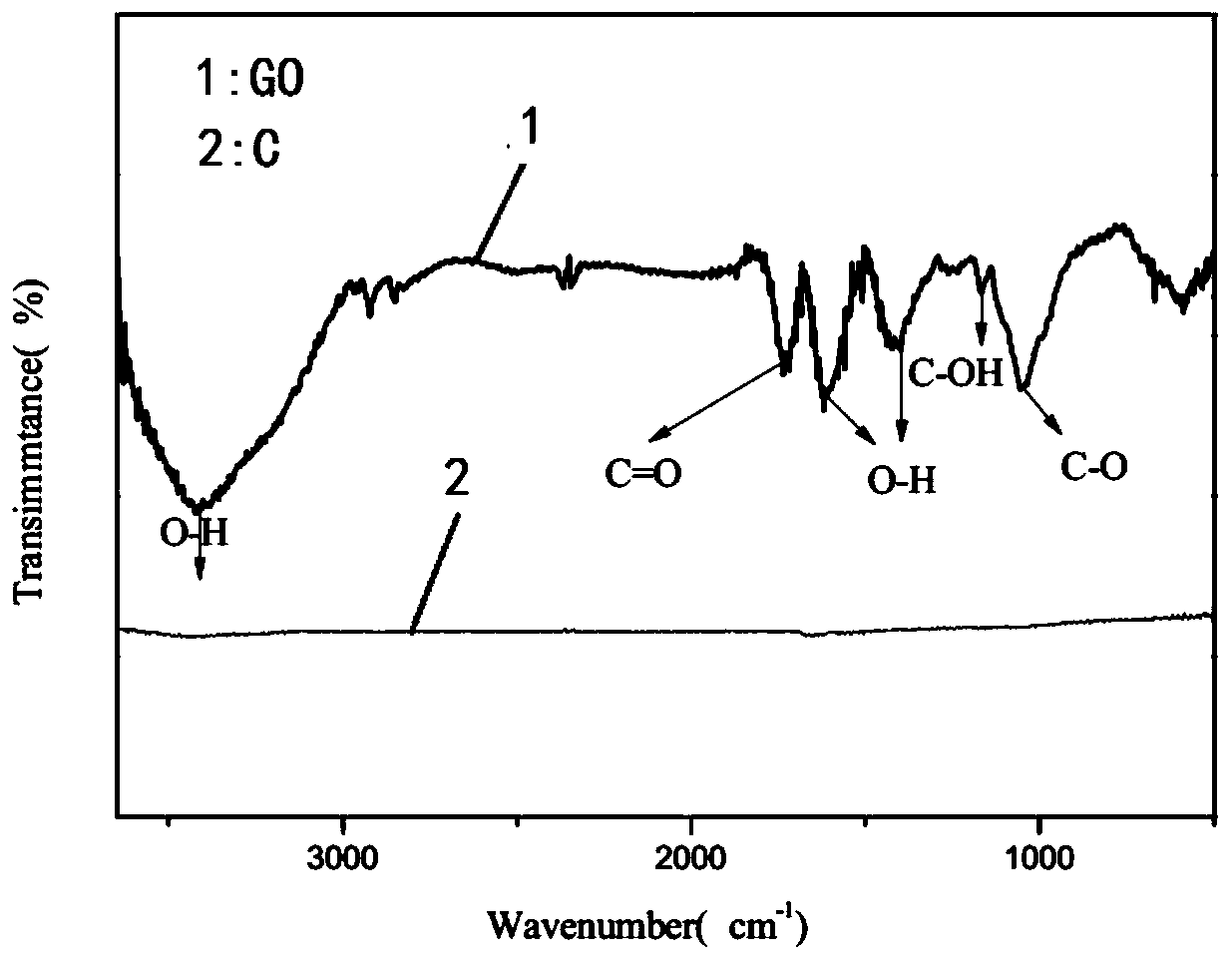

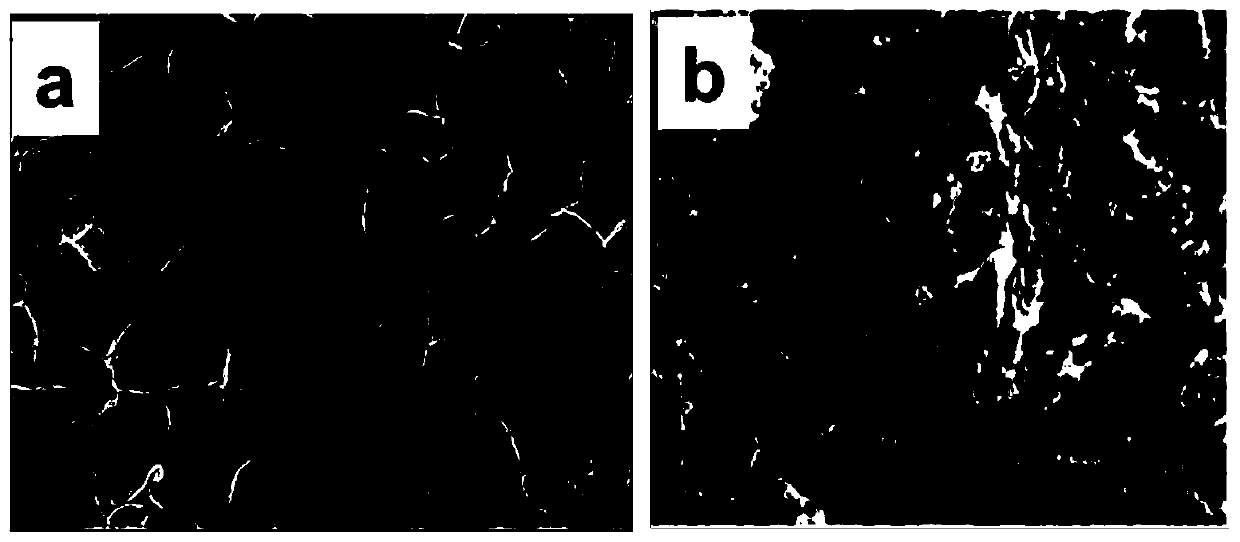

A graphene aerogel, carbon nanotube technology, applied in the field of advanced functional composite materials, nanoporous materials - carbon aerogels, to achieve the effect of increasing mechanical properties, building stability, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preparation method of carbon nanotube / graphene oxide airgel / polystyrene composite material described in this embodiment comprises the following steps:

[0044] S0, adopt improved Hummers method to prepare graphene oxide suspension

[0045] S0-1. Weigh 8g of graphite and 3.5g of sodium nitrate as required, mix them into a three-neck flask containing 360mL of concentrated sulfuric acid with a concentration of 98%, mechanically stir in an ice bath for 1h, then add 20g of potassium permanganate, and place the mixture on ice. Continue stirring in the bath for 2 hours, raise the temperature of the water bath to 35°C, continue stirring for 14 hours, slowly add 1050 mL of deionized water twice, and finally add 50 mL of hydrogen peroxide solution with a volume concentration of 30%, and react for 30 minutes. Ultrasonic stripping under 30KHz ultrasound for 30 minutes to obtain a graphene oxide mixture;

[0046] S0-2, adding a hydrochloric acid solution with a concentration of...

Embodiment 2

[0064] The preparation method of carbon nanotube / graphene oxide airgel / polystyrene composite material described in this embodiment comprises the following steps:

[0065] S0, adopt improved Hummers method to prepare graphene oxide suspension

[0066] S0-1. Weigh 8g of graphite and 4g of sodium nitrate as required, mix them into a three-neck flask with 350mL concentration of 98% concentrated sulfuric acid, stir mechanically in an ice bath for 1h, then add 24g of potassium permanganate, and place in an ice bath Continue to stir for 2 hours, raise the temperature of the water bath to 25°C, continue to stir for 10 hours, slowly add 1080 mL of deionized water twice, and finally add 50 mL of hydrogen peroxide solution with a volume concentration of 30%, react for 30 minutes, and finally at a frequency of 30KHz Ultrasonic exfoliation for 60 minutes under the ultrasonic to obtain a graphene oxide mixture;

[0067] S0-2, adding the hydrochloric acid solution with a concentration of 1....

Embodiment 3

[0078] The preparation method of carbon nanotube / graphene oxide airgel / polystyrene composite material described in this embodiment comprises the following steps:

[0079] S0, adopt improved Hummers method to prepare graphene oxide suspension

[0080] S0-1. Weigh 4g of graphite and 1.9g of sodium nitrate as required, mix them into a three-necked flask containing 180mL of concentrated sulfuric acid with a concentration of 98%, mechanically stir in an ice bath for 1h, then add 11g of potassium permanganate, and place the mixture on ice. Continue to stir in the bath for 2 hours, raise the temperature of the water bath to 30°C, and continue to stir for 12 hours. Slowly add 540 mL of deionized water twice, and finally add 20 mL of hydrogen peroxide solution with a volume concentration of 30%, and react for 60 minutes. Ultrasonic stripping under 40KHz ultrasound for 30 minutes to obtain a graphene oxide mixture;

[0081] S0-2, adding the hydrochloric acid solution with a concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com