Hydrophobic monomer, high molecular polymer, and preparation methods and application thereof

A high-molecular polymer, hydrophobic monomer technology, applied in the preparation of organic compounds, the preparation of carbamate derivatives, the composition of drilling holes, etc. Problems such as flushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

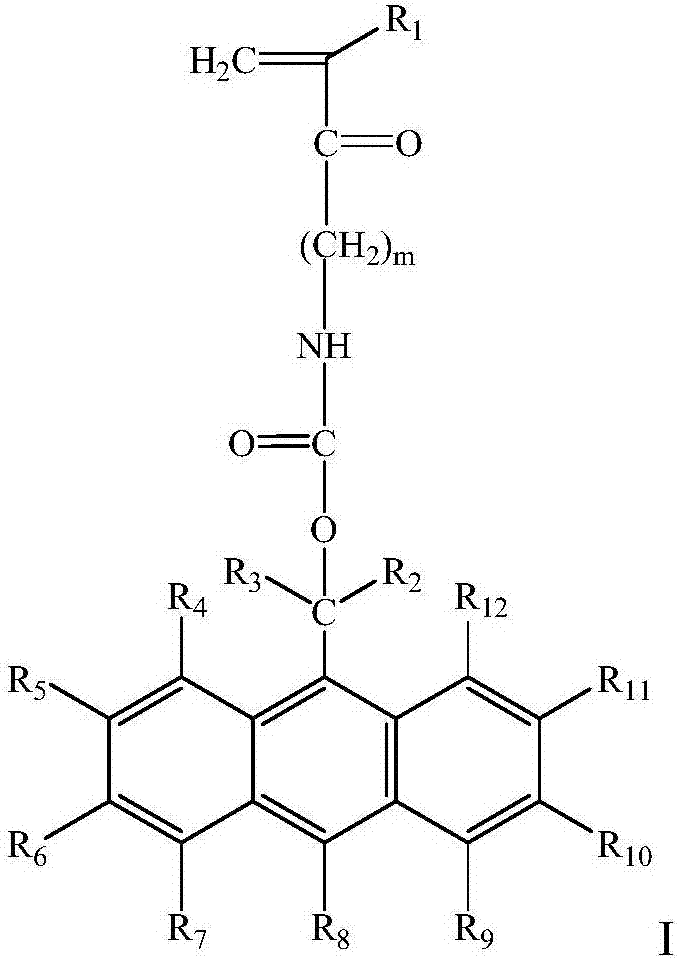

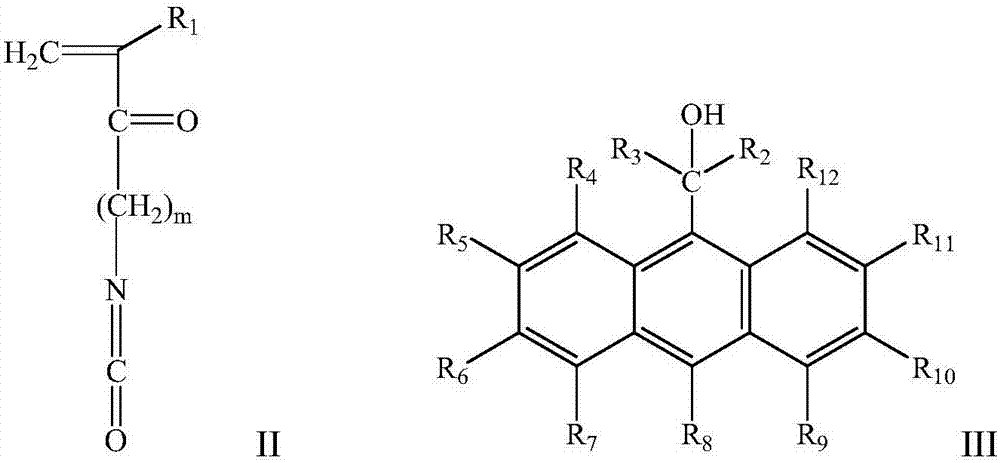

[0040] The synthesis of embodiment 1 hydrophobic monomer:

[0041] Add 500 mL of acetone and 22.23 g of 1-(9-anthracenyl)ethanol into a dry three-neck flask equipped with a stirrer, condenser and dropping funnel, and stir until the 1-(9-anthracenyl)ethanol is fully dissolved. The water bath was heated to a temperature of 50°C, and vacuum was applied for 2 hours to remove moisture. Under nitrogen protection, 0.0124 g of dibutyltin dilaurate was added. 20.73 g of 3-isopropyl-dimethylbenzyl isocyanate in the dropping funnel was dropped into a three-necked flask, reacted for 6 hours, and distilled under reduced pressure to remove acetone, and the crude product of the target molecule was obtained. The crude product was rinsed with methanol three times, placed in an oven at 65°C until constant weight, and the target product was obtained.

Embodiment 2

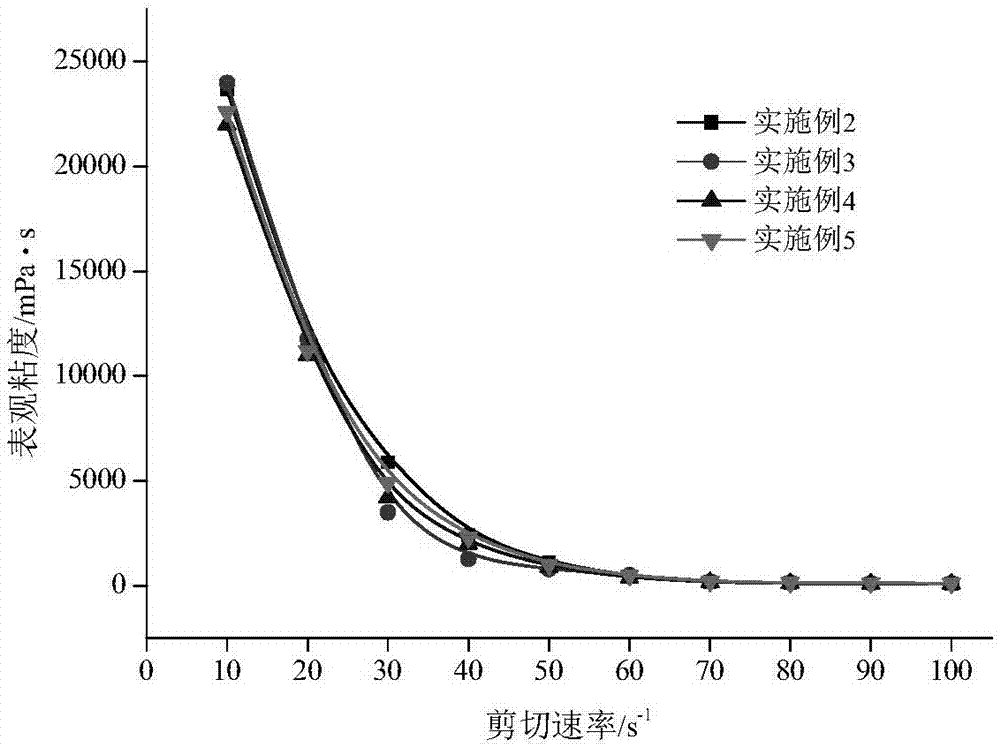

[0043] Add 35.54 g of acrylamide, 28.82 g of acrylic acid and 720 mL of water into the reactor in sequence, stir until completely dissolved, and adjust the pH of the solution to 8.0 with a 50.0% NaOH solution by mass percent. Add 9.44g of the anthracenyl-containing hydrophobic monomer and 41.77g of sodium dodecylbenzenesulfonate prepared in Example 1 under stirring, and continue stirring to solubilize the hydrophobic monomer in the sodium dodecylbenzenesulfonate micelle In the solution, nitrogen was blown for 1 hour to remove dissolved oxygen in the solution. Add 0.7380g K 2 S 2 o 8 , continue to blow nitrogen and raise the temperature to 50° C., and react for 10.5 hours to obtain a gel-like product. Wash with absolute ethanol, pulverize and dry to obtain the target product.

Embodiment 3

[0045] Add 21.32g of acrylamide, 9.91g of N-methyl-N-vinylacetamide, 36.03g of acrylic acid and 1277.94mL of water in sequence in the reactor, stir until completely dissolved, and adjust with a NaOH solution with a mass percent concentration of 50.0%. The pH of the solution was brought to 8.5. Add 5.66g of anthracenyl-containing hydrophobic monomers prepared in Example 1 and 26.2g of sodium octadecylsulfonate under stirring conditions, and continue stirring to solubilize the hydrophobic monomers in the sodium octadecylsulfonate micelles. Nitrogen was sparged for 45 minutes to remove dissolved oxygen in the solution. Add 0.5g (NH 4 ) 2 S 2 o 8 , continue to pass nitrogen and heat up to the predetermined reaction temperature of 55° C., and react for 8 hours to obtain a gelatinous product. Wash with absolute ethanol, pulverize and dry to obtain the target product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com