Functional denitration filter material prepared with ring opening polymerization method

A technology of ring-opening polymerization and functionalization, which is applied in the direction of physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, separation methods, etc., and can solve problems that do not involve chemical reactions and are not particularly fast. , to achieve the effect of simple reaction synthesis method and operation, short test cycle and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

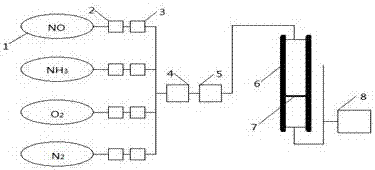

Method used

Image

Examples

Embodiment 1

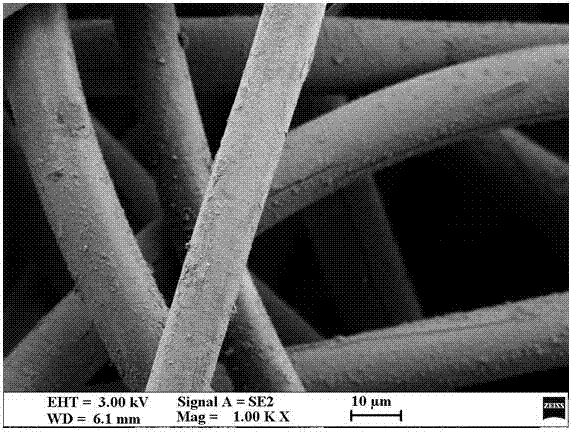

[0023] First weigh 32ml of concentrated nitric acid and add it to 68ml of deionized water to prepare a dilute nitric acid solution with a volume fraction of 30%. Then put two pieces of polyphenylene sulfide (PPS), and treat it in a water bath at 80°C for 2 hours. After the treatment, clean the PPS with deionized water and ethanol, and then dry the filter material in an oven for later use.

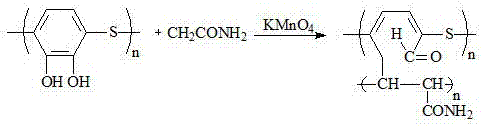

[0024] Add 1.2g of acrylamide to a beaker containing 50ml of deionized water, stir evenly, accurately weigh the mass of the above-mentioned filter material to 0.6g, then add the above-mentioned treated PPS to the prepared solution, and place it at room temperature for ultrasonic dispersion for 2 hours. After the surface of PPS is fully wrapped by acrylamide, move it into a water bath, and then pass in protective gas nitrogen until the reaction bottle is filled with nitrogen, accurately weigh 0.12g of potassium permanganate, and prepare KMnO with a concentration of 0.02M 4 solution, slowly p...

Embodiment 2

[0027] First weigh 32ml of concentrated nitric acid and add it to 68ml of deionized water to make a 30% (v / v) dilute nitric acid solution. Then put two pieces of polyphenylene sulfide (PPS), and treat it in a water bath at 80°C for 2 hours. After the treatment, clean the PPS with deionized water and ethanol, and then dry the filter material in an oven for later use.

[0028] Add 1.8g of acrylamide to a beaker containing 50ml of deionized water, stir evenly, accurately weigh the mass of the above-mentioned filter material to 0.6g, then add the above-mentioned treated PPS to the prepared solution, and place it at room temperature for ultrasonic dispersion for 2 hours. After the surface of PPS is fully wrapped by acrylamide, move it into a water bath, and then pass in protective gas nitrogen until the reaction bottle is filled with nitrogen, accurately weigh 0.12g of potassium permanganate, and prepare KMnO with a concentration of 0.02M 4 solution, slowly pour the prepared soluti...

Embodiment 3

[0031] First weigh 32ml of concentrated nitric acid and add it to 68ml of deionized water to make a 30% (v / v) dilute nitric acid solution. Then put two pieces of polyphenylene sulfide (PPS), and treat it in a water bath at 80°C for 2 hours. After the treatment, clean the PPS with deionized water and ethanol, and then dry the filter material in an oven for later use.

[0032] Add 2.4g of acrylamide to a beaker containing 50ml of deionized water, stir evenly, accurately weigh the mass of the above-mentioned filter material to 0.6g, then add the above-mentioned treated PPS to the prepared solution, and place it at room temperature for ultrasonic dispersion for 2 hours. After the surface of PPS is fully wrapped by acrylamide, move it into a water bath, and then pass in protective gas nitrogen until the reaction bottle is filled with nitrogen, accurately weigh 0.12g of potassium permanganate, and prepare KMnO with a concentration of 0.02M 4 solution, slowly pour the prepared solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com