A mugwort crisp biscuit and its preparation method

A technology of crispy biscuits and biscuits, which is applied in the field of mugwort crispy biscuits and its production, can solve the problems that the nutritional value is not well utilized, mugwort products have a single taste, and cannot obtain a good taste, and achieve Overcome the effects of unbalanced dietary nutrition, stimulate food desire, facilitate preservation and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

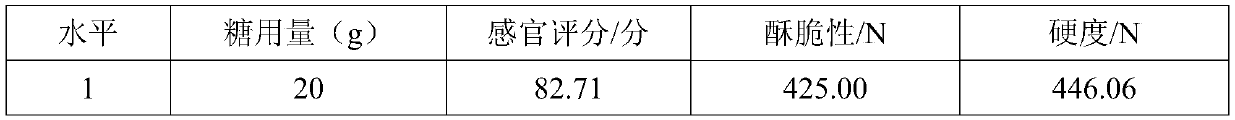

Embodiment 1

[0038] Selection of raw materials: Artemisia mugwort is the local county town of Baise, Guangxi; Xuejian brand low-gluten cake flour (Henan Xuejian Industrial Co., Ltd.); high-grade white sugar (Taigu Sugar Co., Ltd.); butter (Shanghai Gaofu Food Co., Ltd.) Baicheng drinking water; eggs (commercially available high-quality products); Shukeman edible corn starch (Zhuhai Jindi Chao Food Co., Ltd.); edible baking soda (Tianjin Hongyi Food Manufacturing Co., Ltd.); edible ammonium bicarbonate (an Qiye Yeast Co., Ltd.); seaweed iodized salt (Yinpeng multi-variety salt company in Guangxi Zhuang Autonomous Region).

[0039] A mugwort crisp biscuit is made from the following raw materials: 100g of low-gluten flour, 2g of mugwort powder, 10g of butter, 30g of white sugar, 9g of water, 0.08g of ammonium bicarbonate, 3g of starch, and 8g of egg yolk.

[0040] The preparation method of the above-mentioned mugwort crisp biscuit comprises the steps:

[0041] (1) Pretreatment of raw and auxil...

Embodiment 2

[0054] A mugwort crisp biscuit, made of the following raw materials in parts by weight: 105 parts of low-gluten flour, 3 parts of mugwort powder, 12 parts of butter, 35 parts of white sugar, 11 parts of water, 0.09 parts of ammonium bicarbonate, starch 4 parts, 10 parts of egg yolk.

[0055] The preparation method of the above-mentioned mugwort crisp biscuit comprises the following steps:

[0056] (1) Pretreatment of raw and auxiliary materials

[0057] A. Production of mugwort powder: put 100g of fresh mugwort into a mixed solution of 100mL of 3% saline and 200mL of 1% baking soda for 20 minutes, then wash twice with pure water to remove impurities After draining, put it into an environment with a temperature of 60° C. and dry it for 18 hours until the moisture content is 4%. After crushing, pass through a 100-mesh sieve to obtain mugwort powder for later use;

[0058] B. Pretreatment of butter: heat and melt the container containing butter in warm water at 50°C;

[0059] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com