Method for rapidly determining molecular weight, distribution and impurity content of polyethylene glycol derivative

A polyethylene glycol, rapid determination technology, applied in the field of analysis and testing, can solve the problem of few molecular weight methods, and achieve the effect of fast analysis speed and high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

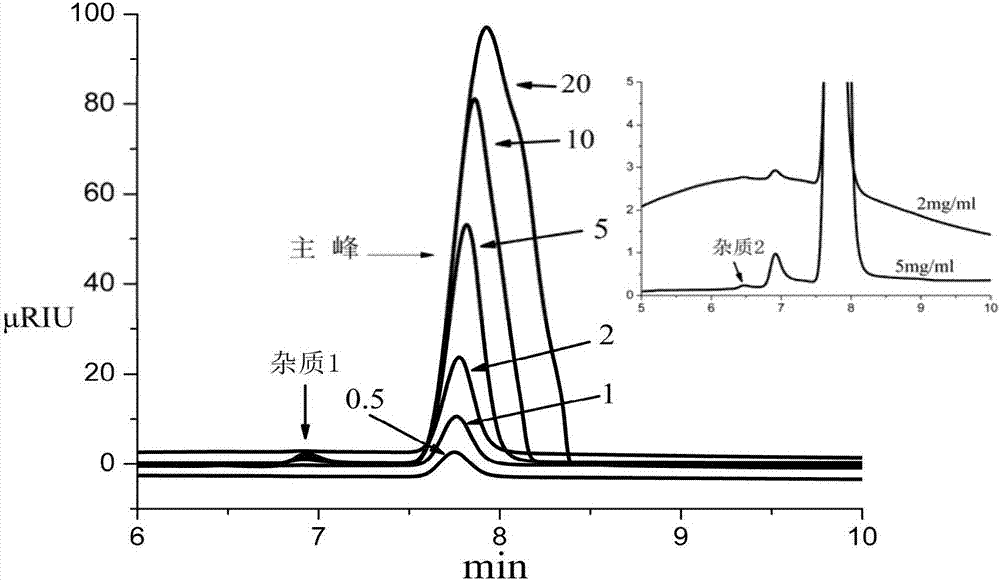

[0032] The determination of the molecular weight, distribution and impurity content of monomethoxy polyethylene glycol propyl aldehyde (mPEG_pALD) includes the following steps:

[0033] 1.1 Solution preparation

[0034] Preparation of standard solution: Take 2.0 mg of polyethylene glycol (PEG) standard and the peak molecular weight (M p ) Respectively 2010Da, 3120Da, 6240Da, 8600Da, 12000Da, 23000Da, 40000Da, 230,000Da, 478000Da, add 1.5mL of methanol and water with a volume ratio of 95:5, leave it at room temperature for 24h, and wait until the standard is completely dissolved.

[0035] Preparation of sample solution: Weigh 50 mg of mPEG_pALD sample into a 10 mL volumetric flask, add methanol and water with a volume ratio of 95:5 to dissolve it to a constant volume, and wait for measurement.

[0036] 1.2 Experimental conditions

[0037] Chromatographic conditions: Column: ACQUITY APC XT 450 (4.6×150mm, 2.5μm), molecular weight range: 20000Da~400000Da; ACQUITY APC XT 200 (4.6×150mm, 2.5...

Embodiment 2

[0049] The determination of the molecular weight, distribution and impurity content of Y-shape PEG-NH2 includes the following steps:

[0050] 2.1 Solution preparation

[0051] Preparation of standard solution: Take 2.0 mg of polyethylene glycol (PEG) standard and the peak molecular weight (M p ) Are 600Da, 1500Da, 2010Da, 3120Da, 6240Da, 8600Da, 12000Da, 23000Da, and 40000Da respectively. Add 1.5mL of methanol and water with a volume ratio of 90:10% and leave it at room temperature for 24h. After the standard is completely dissolved, it will be tested.

[0052] Preparation of sample solution: Weigh 40 mg of Y-type polyethylene glycol amine sample into a 10 mL volumetric flask, add methanol and water with a volume ratio of 90:10 to dissolve to a constant volume, and wait for measurement.

[0053] 2.2 Experimental conditions

[0054] Chromatographic conditions: Chromatographic column: ACQUITY APC XT 200 (4.6×150mm, 2.5μm), molecular weight range: 3000Da~70,000Da; ACQUITY APC XT 45 (4.6×15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peak molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com