Smelting method and production technology of electrical steel

A technology of smelting method and production process, which is applied in the field of smelting method and production process of electrical steel, can solve problems such as poor cleanliness, achieve the effects of reducing the generation of inclusions, improving the purification effect, and promoting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

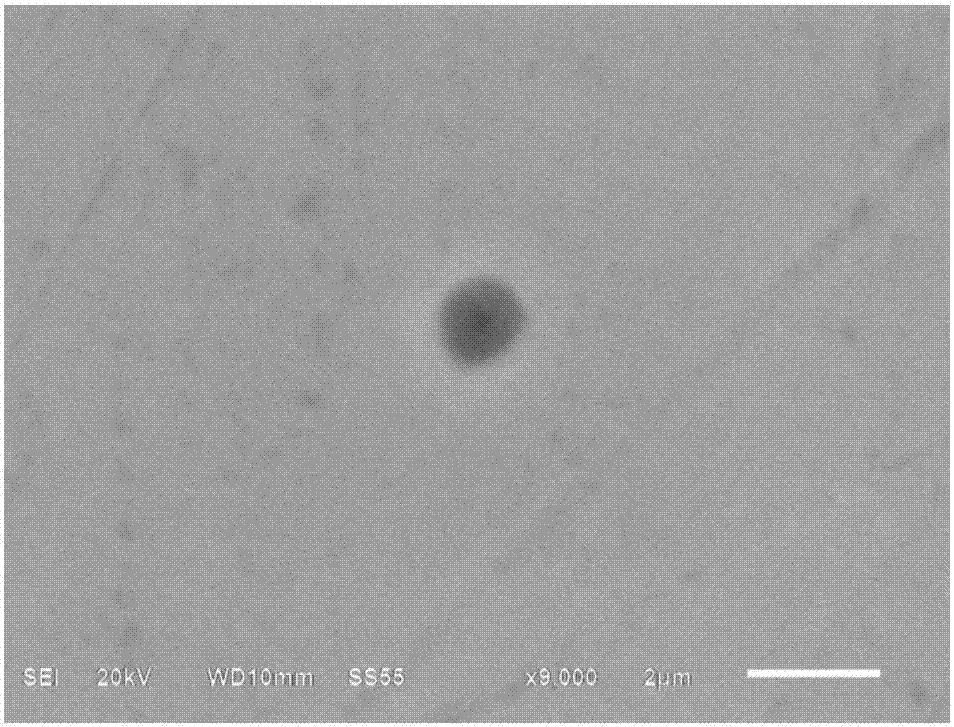

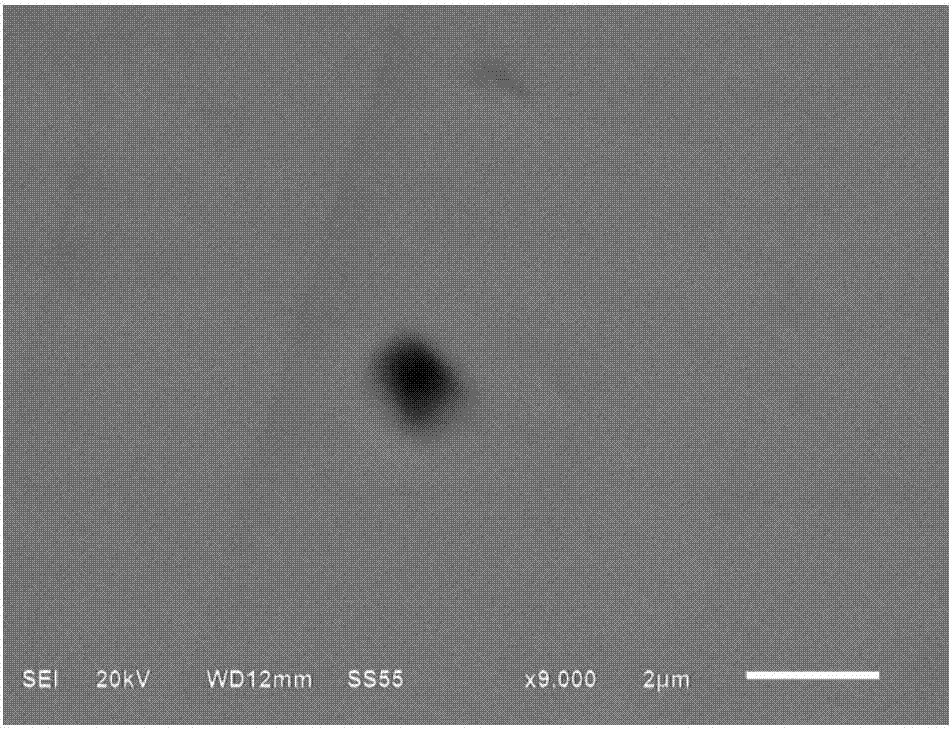

Image

Examples

Embodiment 1

[0045] Such as Figure 5 As shown, a kind of electrical steel smelting method of the present embodiment, concrete steps are as follows:

[0046] S100, molten iron pretreatment

[0047] Control the slag removal rate ≥ 95%, control S ≤ 0.003% during molten iron pretreatment, and control the temperature of molten iron ≥ 1350°C before desiliconization; the slag removal rate in this embodiment is 96%, control S: 0.003% during pretreatment of molten iron, desiliconization The temperature of the former molten iron is 1360°C;

[0048] S200, converter smelting

[0049] The temperature of the molten iron entering the furnace is ≥1250°C. In this example, it is 1280°C. Scrap steel with low sulfur and low phosphorus content is used, S≤0.003%, P≤0.02%, and the ratio of scrap steel into the furnace is ≤10%. 9%. During the whole process of smelting, argon or nitrogen gas is blown at a low level. In this example, argon gas is used, and a deoxidizer is added for deoxidation. The molten stee...

Embodiment 2

[0075] The basic content of this embodiment is the same as that of Example 1, except that the cleaning agent is in the form of granules, the cleaning agent is in the form of spherical particles, and the diameter of the particles is 5-10mm; the cleaning agent includes effective components and bonding components, and the effective components The mass ratio to the adhesive component is (5-10):1, preferably 5:1 in this embodiment.

[0076] The effective components in the purification agent of this embodiment also include graphite powder, red jade soil and magnesium-manganese alloy; the effective components are composed according to the following mass parts, 50-70 parts of metal aluminum, 20-40 parts of lime powder, and 0-30 parts of graphite powder part, 5-20 parts of titanium dioxide, 5-15 parts of silicon carbide powder, 2-4 parts of biomass, 0-1 part of red jade soil, 0-2 part of magnesium-manganese alloy; the present embodiment is 50 kg of metal aluminum, 20 kg of lime powder, ...

Embodiment 3

[0080] The basic content of this embodiment is the same as that of Example 1, except that the adhesive component of the purifying agent also includes starch and kaolin, and the adhesive component is composed of the following parts by mass: 60-80 parts of kaolin, 20-40 parts of sulfonated phenolic resin parts, starch 0-10 parts, oil sands 0-5 parts. This embodiment is composed according to the following mass: 80 kg of kaolin, 40 kg of sulfonated phenolic resin, 5 kg of starch, 2 kg of oil sand, and the test results of the steel sample are basically the same as in embodiment 1. The starch and oil sand in the bonding component play the role of bonding in the early stage, and in the later stage, they will participate in the deoxidation reaction in molten steel and generate gas, thereby promoting the floating of inclusions and improving the deoxidation efficiency at the same time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com