Insulating ceramic for high-voltage power transmission line

A high-voltage transmission line, insulating ceramic technology, applied in insulators, circuits, electrical components and other directions, can solve problems such as damage to the use and operating life of the line, insulators are prone to leakage, and short service life. hydrophobic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

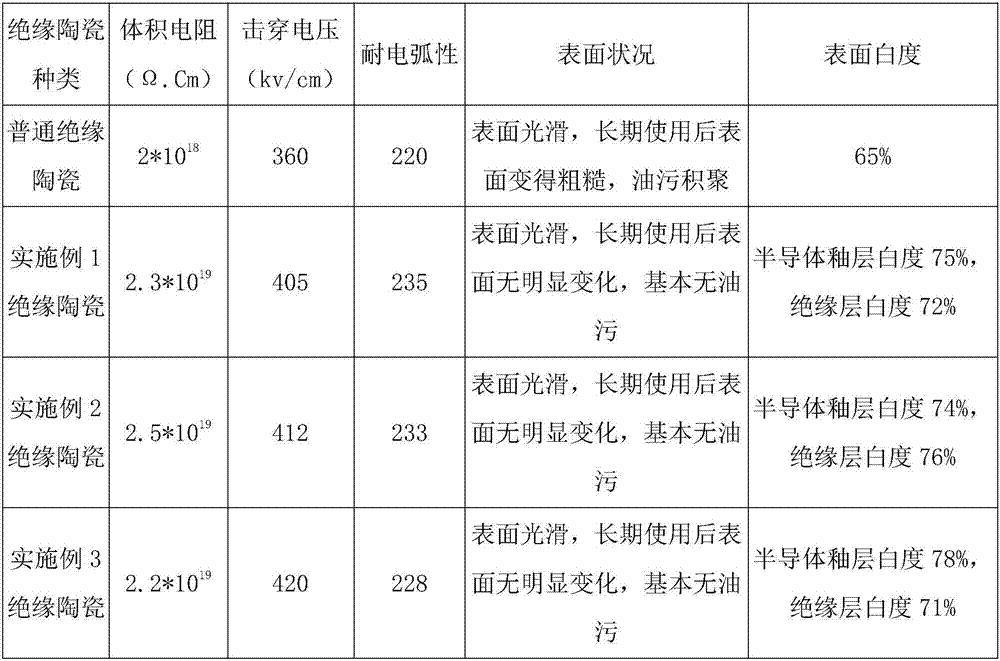

Embodiment 1

[0022] An insulating ceramic specially used for high-voltage transmission lines. The insulating ceramic comprises a ceramic body, a semiconductor glaze layer coated on the outer surface of the ceramic body, and an insulating layer adhered to the outside of the semiconductor glaze layer.

[0023] Described semiconductor glaze is made up of the raw material of following weight part:

[0024] 17 parts of magnesium oxide, 15 parts of barium carbonate, 9 parts of cobalt oxide, 5 parts of quartz, 12 parts of alumina powder, 5 parts of lime, 8 parts of vermiculite, 12 parts of bentonite, 17 parts of powdered titanium dioxide, 15 parts of perlite, oxide 9 parts of iron, 20 parts of white glaze base material, 8 parts of gloss agent, 5 parts of anti-corrosion agent;

[0025] Described white glaze base-material is made up of the raw material of following weight part:

[0026] 3 parts of potassium feldspar, 5 parts of zinc oxide, 8 parts of Xinhui powder, 4 parts of washed kaolin, 5 part...

Embodiment 2

[0036] An insulating ceramic specially used for high-voltage transmission lines. The insulating ceramic comprises a ceramic body, a semiconductor glaze layer coated on the outer surface of the ceramic body, and an insulating layer adhered to the outside of the semiconductor glaze layer.

[0037] Described semiconductor glaze is made up of the raw material of following weight part:

[0038] 23 parts of magnesium oxide, 20 parts of barium carbonate, 11 parts of cobalt oxide, 6 parts of quartz, 14 parts of alumina powder, 6 parts of lime, 9 parts of vermiculite, 13 parts of bentonite, 23 parts of powdered titanium dioxide, 20 parts of perlite, oxidized 11 parts of iron, 23 parts of white glaze base material, 9 parts of gloss agent, 6 parts of anti-corrosion agent;

[0039] Described white glaze base-material is made up of the raw material of following weight part:

[0040] 5 parts of potassium feldspar, 7 parts of zinc oxide, 12 parts of Xinhui powder, 7 parts of washed kaolin, ...

Embodiment 3

[0050] An insulating ceramic specially used for high-voltage transmission lines. The insulating ceramic comprises a ceramic body, a semiconductor glaze layer coated on the outer surface of the ceramic body, and an insulating layer adhered to the outside of the semiconductor glaze layer.

[0051] Described semiconductor glaze is made up of the raw material of following weight part:

[0052] 28 parts of magnesium oxide, 25 parts of barium carbonate, 12 parts of cobalt oxide, 7 parts of quartz, 15 parts of alumina powder, 8 parts of lime, 10 parts of vermiculite, 15 parts of bentonite, 28 parts of powdered titanium dioxide, 25 parts of perlite, oxidized 12 parts of iron, 25 parts of white glaze base material, 10 parts of gloss agent, 7 parts of anti-corrosion agent;

[0053] Described white glaze base-material is made up of the raw material of following weight part:

[0054] 7 parts of potassium feldspar, 9 parts of zinc oxide, 15 parts of Xinhui powder, 9 parts of washed kaolin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com