Chemical heat exchanger

A heat exchanger and chemical technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problem of low thermal insulation performance and waterproof performance, low stability of support on the ground, poor corrosion resistance, etc. problem, to achieve the effect of high waterproof performance, wide application range and strong thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

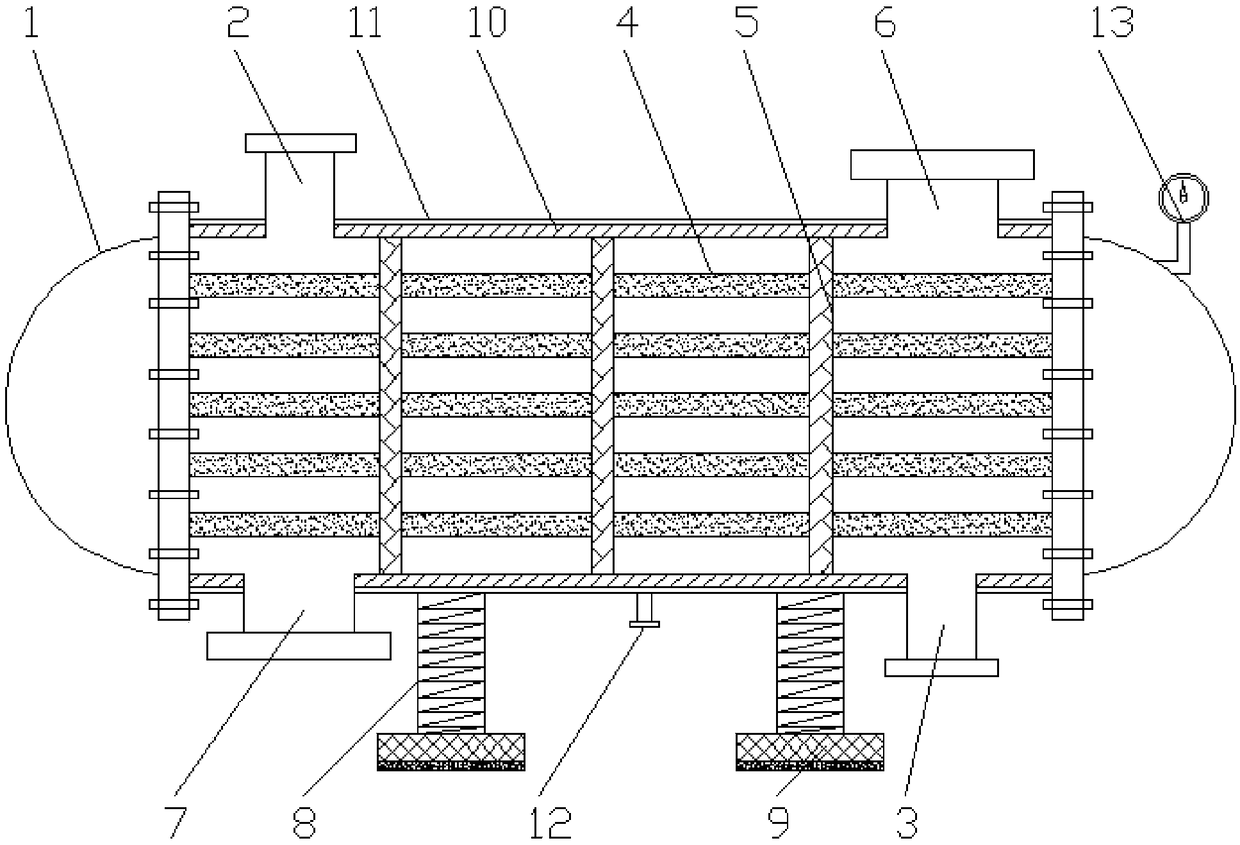

[0016] see figure 1 , the present invention provides a technical solution: a chemical heat exchanger, the structure of which includes a heat exchanger body 1, a liquid inlet 2, a liquid discharge 3, a heat exchange tube 4, a baffle 5, an exhaust port 6, Shell-side tube interface 7 and support legs 8, the top left side of the heat exchanger body 1 is provided with a liquid inlet 2, the top right side of the heat exchanger body 1 is provided with an exhaust port 6, the heat exchange The left side of the bottom of the heat exchanger body 1 is provided with a shell-side pipe interface 7, the bottom right side of the heat exchanger body 1 is provided with a liquid discharge port 3, and the inside of the heat exchanger body 1 is distributed with heat ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com