Superconducting cable end socket structure

A technology for superconducting cables and terminals, which is applied in the directions of superconducting devices, superconducting/high-conducting conductors, and the usage of superconducting elements. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

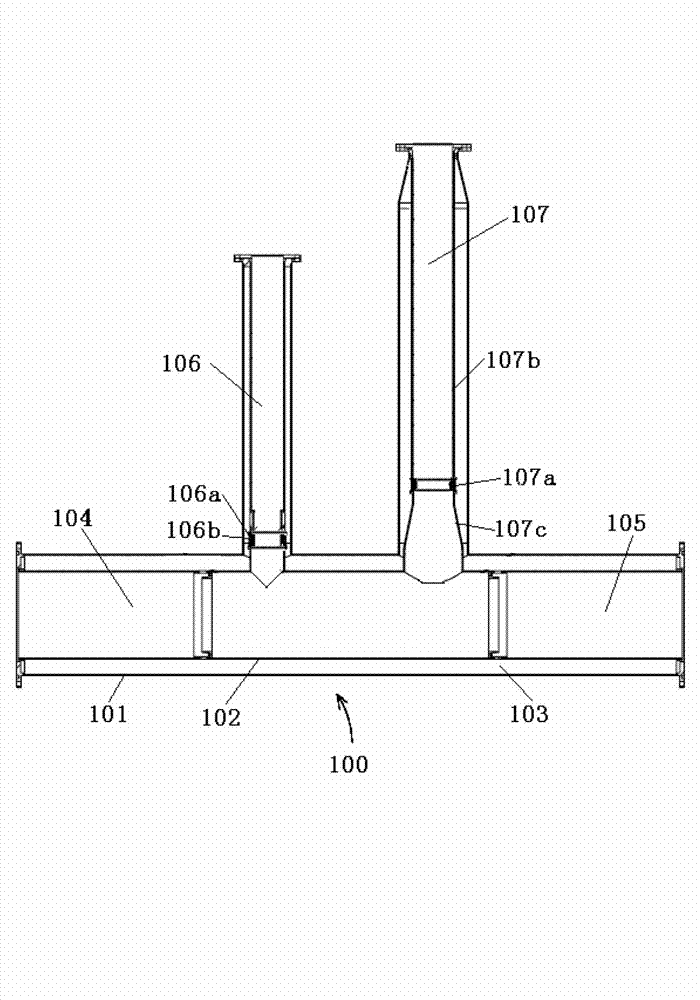

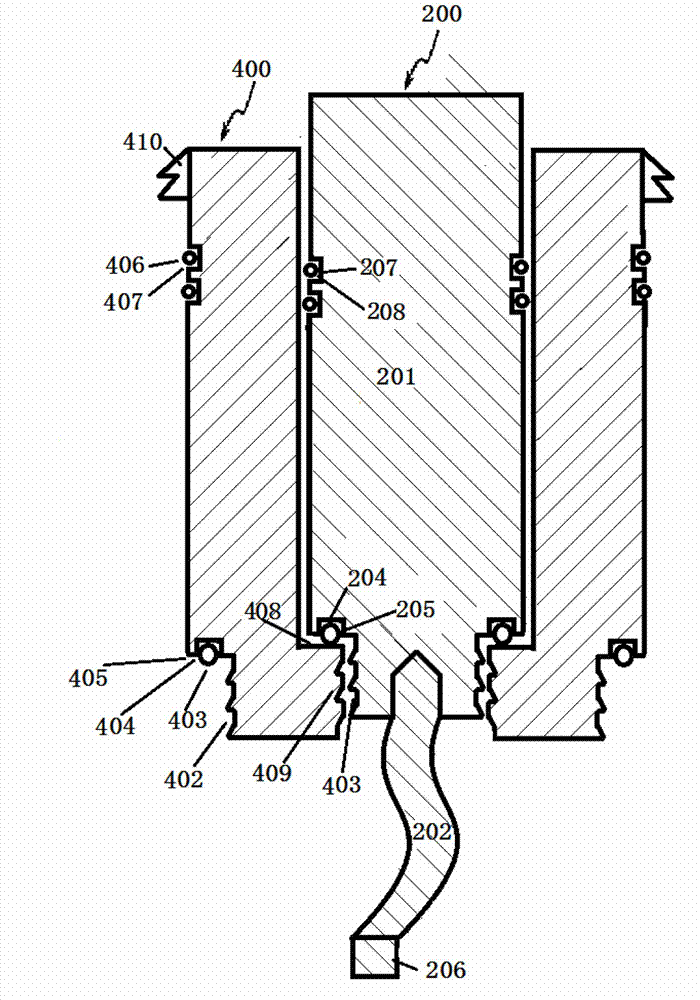

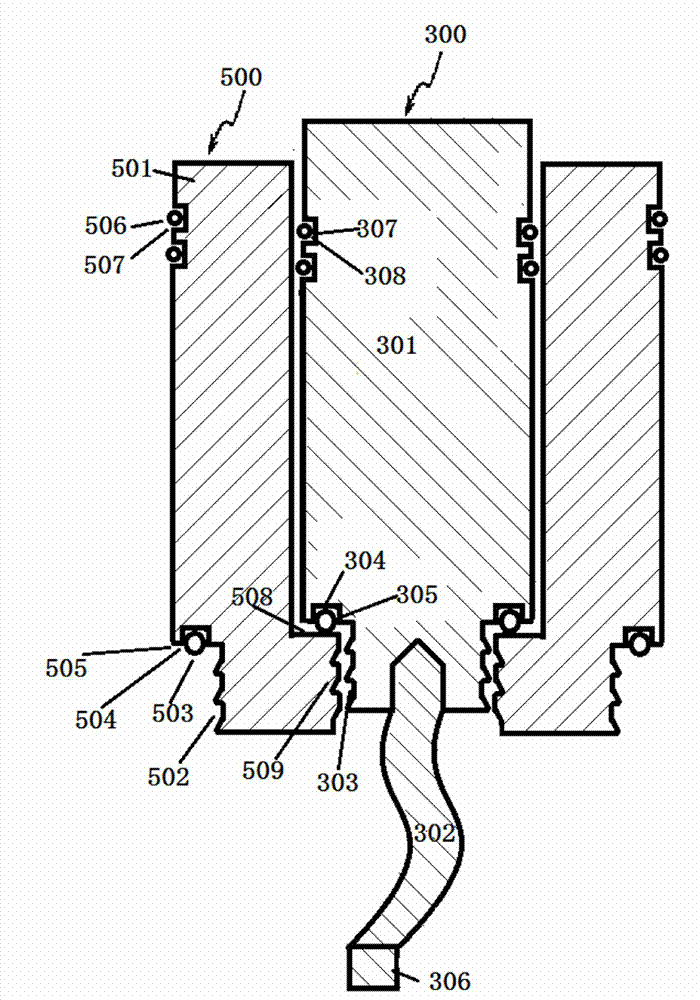

[0028] Such as figure 1 As shown, the superconducting cable terminal structure of the present invention includes a terminal thermostat 100 for accommodating the superconducting cable body. The terminal thermostat is cylindrical and has four connected interface outlet pipes 104, 105, 106 and 107. , wherein, the two interface lead-out pipes 104, 105 connected with the cable body and the refrigeration system are respectively located at the two ends of the cylindrical end thermostat and are arranged in parallel with it at 180°, so as to facilitate the current leads of the conductive layer and the shielding layer (200, 300 ) with cable body 600 for installation. It can be made into an integral type, or it can also be a split type. The two interface lead-out tubes 106, 107 of the conductive layer current lead and the shielded layer current lead are vertically vertical on one side of the thermostat at the end, and the positions are respectively corresponding to the superconducting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com