Bismuth oxychloride near-infrared high-reflective insulation pigment particle and preparation method

A technology of bismuth oxychloride and pigment particles, applied in chemical instruments and methods, inorganic chemistry, bismuth compounds, etc., can solve the problems of reduced reflection efficiency, decreased near-infrared reflectivity, and single color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

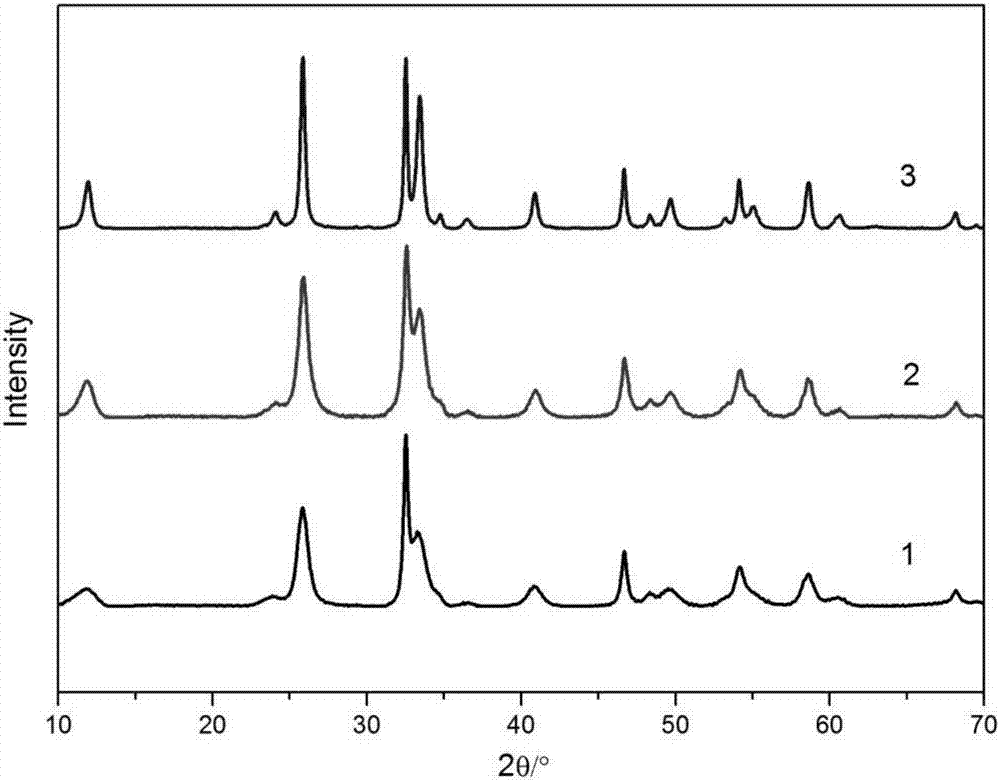

[0026] Preparation of bismuth oxychloride near-infrared high-reflective heat-insulating pigment

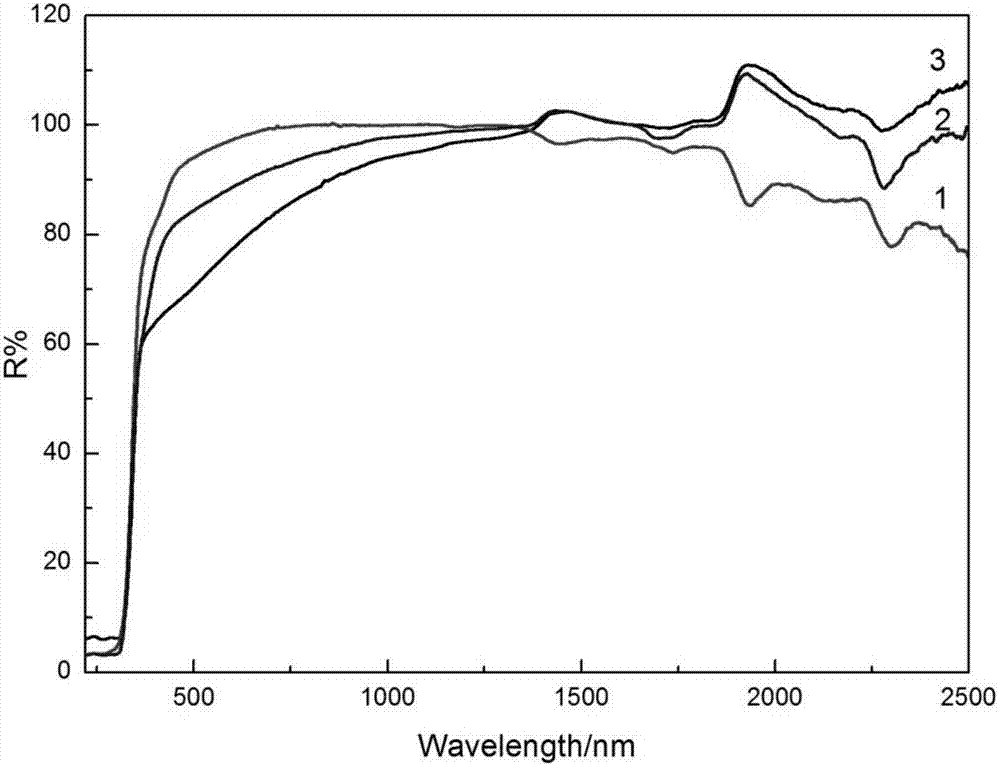

[0027] According to Bi(NO 3 ) 3 5H 2 O, HCl, C 6 h 8 o 7 ·H 2 O molar ratio is 1:1:0.5 and the resulting mixture is dissolved in 100mL of water (wherein Bi(NO 3 ) 3 5H 2 The concentration of O is 0.01mol / L), adjust the pH=3 with concentrated hydrochloric acid, and then ultrasonically disperse for 30 minutes, then transfer the mixture into a polytetrafluoroethylene-lined autoclave with a volume of 300ml, seal it, put it into an oven, and keep At 100°C, react for 4h. Then, as the furnace cooled to room temperature, the product in the reactor was washed alternately with distilled water and absolute ethanol three times, and then the powder was dried in a vacuum oven at 70° C. for 12 hours. The obtained powder was then put into a mortar and ground for 10 minutes to obtain a white powder. The near-infrared spectrum measured embodiment 1 pigment sample is 82.0% at 1000nm-2500n...

Embodiment 2

[0029] Preparation of bismuth oxychloride near-infrared high-reflective heat-insulating pigment (a kind of bismuth oxychloride near-infrared high-reflective heat-insulation pigment 2 preparation) according to Bi(NO 3 ) 3 5H 2 O, KCl, C 6 h 8 o 7 ·H 2 O molar ratio is 1:1:0.5 and the resulting mixture is dissolved in 100mL of water (wherein Bi(NO 3 ) 3 5H 2 The concentration of O is 0.01mol / L), adjust the pH=3 with concentrated hydrochloric acid, and then ultrasonically disperse for 30 minutes, then transfer the mixture into a polytetrafluoroethylene-lined autoclave with a volume of 300ml, seal it, put it into an oven, and keep At 120°C, react for 5h. Then, as the furnace cooled to room temperature, the product in the reactor was washed alternately with distilled water and absolute ethanol three times, and then the powder was dried in a vacuum oven at 70° C. for 12 hours. Then the obtained powder was put into a mortar and ground for 10 minutes to obtain a khaki powder....

Embodiment 3

[0031] Preparation of bismuth oxychloride near-infrared high-reflective heat-insulating pigment (preparation of bismuth oxychloride near-infrared high-reflective heat-insulation pigment 3)

[0032] According to Bi(NO 3 ) 3 5H 2 O, NaCl, C 6 h 8 o 7 ·H 2 O molar ratio is 1:1:0.5 and the resulting mixture is dissolved in 100mL of water (wherein Bi(NO 3 ) 3 5H 2 The concentration of O is 0.01mol / L), adjust the pH=5 with concentrated hydrochloric acid, and then ultrasonically disperse for 30 minutes, then transfer the mixture into a polytetrafluoroethylene-lined autoclave with a volume of 300ml, seal it, put it into an oven, and keep At 100°C, react for 4h. Then, as the furnace cooled to room temperature, the product in the reactor was washed alternately with distilled water and absolute ethanol three times, and then the powder was dried in a vacuum oven at 70° C. for 12 hours. Then put it into a muffle furnace for calcination at 200°C for 2h. The obtained powder was th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com