Metal coating corrosive liquid

A metal coating and etching solution technology, applied in the preparation of test samples, etc., can solve the problems of difficult to ensure stable corrosion reaction, corrosion of silicon-zirconium alloy coating, difficult to control reaction speed, etc., to facilitate observation and research, corrosion The effect of smooth speed and clear corrosion boundary

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] We measure 10 mL of deionized water, slowly add 30 mL of orthophosphoric acid with a mass fraction of 85% to it, mix well, and then slowly add 30 mL of a prepared aqueous solution of sodium dihydrogen phosphate with a mass fraction of 29%, Mix well and let it stand. When the solution no longer continues to layer, add 10 mL of hydrofluoric acid and 20 mL of ethylene glycol, and stir to make the solution evenly mixed. The obtained solution is a metal plating corrosion solution.

[0016] Take a small amount (1 drop -5 drops) of metal plating corrosion solution, drop it on the surface of the chrome-plated metal plating layer containing hexavalent chromium, and after a while (2 s -10 s), add the reagent containing hexavalent chromium color solution to it, the metal The liquid on the surface of the coating has an obvious color reaction, which proves that a metal coating corrosion solution has an effective corrosion effect.

Embodiment 2

[0018] We measured 35 mL of deionized water, and slowly added 30 mL of the prepared aqueous solution of sodium dihydrogen phosphate with a mass fraction of 29%, mixed well, and slowly added 25 mL of sulfuric acid with a mass fraction of 98% while stirring, and let it stand , After the solution is cooled, when the layering is no longer continued, add 5 mL of hydrofluoric acid and 5 mL of ethylene glycol to it, and stir to make the solution evenly mixed. The obtained solution is a metal plating corrosion solution.

[0019] Take a small amount (1 drop -5 drops) of metal plating corrosion solution, drop it on the surface of the chrome-plated metal plating layer containing hexavalent chromium, and after a while (2 s -10 s), add the reagent containing hexavalent chromium color solution to it, the metal The liquid on the surface of the coating has an obvious color reaction, which proves that a metal coating corrosion solution has an effective corrosion effect.

Embodiment 3

[0021] We measure 50 mL of deionized water, slowly add 15 mL of orthophosphoric acid with a mass fraction of 85% to it, mix well, and then slowly add 25 mL of a prepared aqueous solution of sodium dihydrogen phosphate with a mass fraction of 29%, Mix well and let it stand. When the solution no longer continues to layer, add 5 mL of hydrofluoric acid and 5 mL of ethylene glycol, and stir to make the solution evenly mixed. The obtained solution is a metal plating corrosion solution.

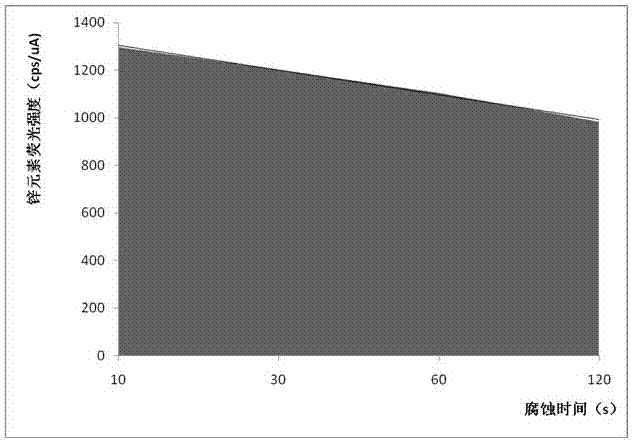

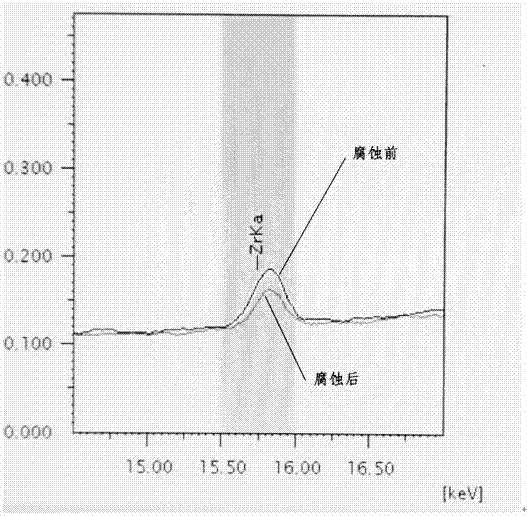

[0022] Take 1 drop of metal plating corrosion solution and drop it on the surface of the zinc-containing metal coating. After 10 s, wash the surface of the metal coating with deionized water to clean the corrosion solution. Afterwards, the surface of the coating was dried, and the fluorescence intensity of the zinc element at the corroded part was measured with an X-ray fluorescence spectrometer, and the reading was recorded. Repeat the above steps to measure the fluorescence intensity of the zinc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com