Method for treating yellow slurry wastewater of corn starch

A corn starch and wastewater treatment technology, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of waste of resources, single recyclables, high cost, reduce raw material costs, solve insufficient production capacity, improve The effect of industry economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

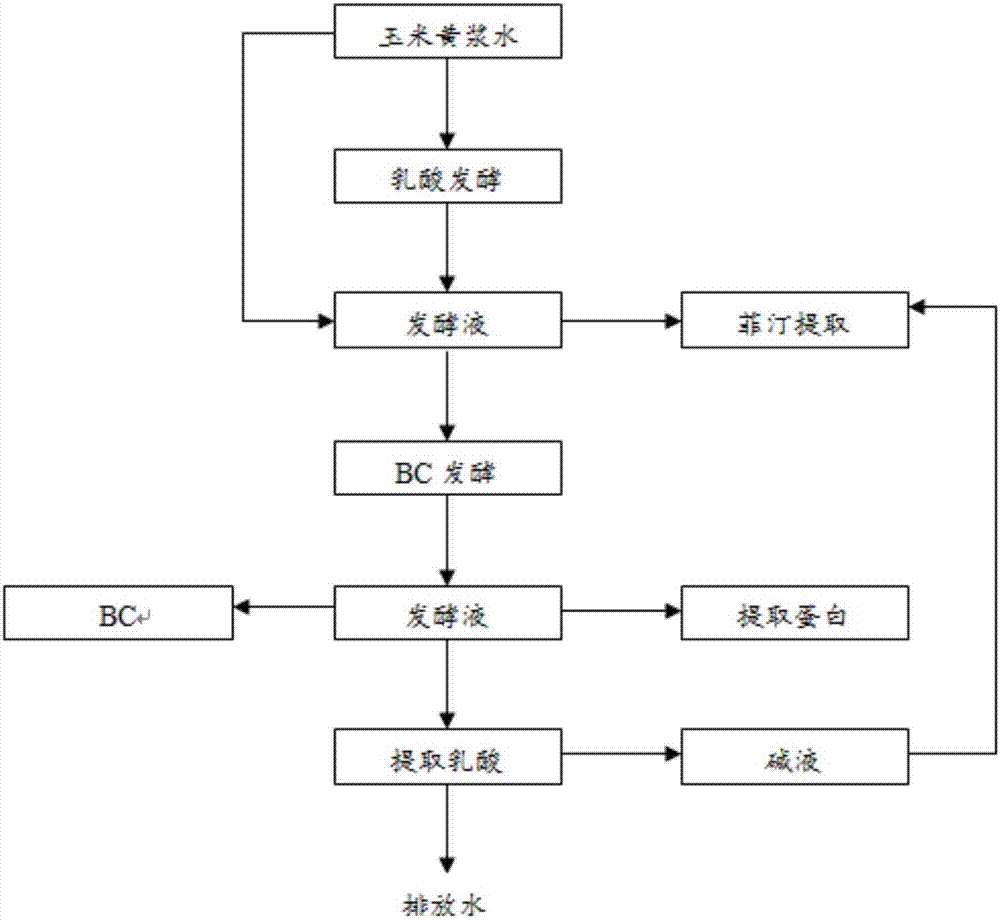

[0045] A method for the treatment of cornstarch yellow slurry wastewater, comprising the following steps:

[0046] 1) Place cornstarch yellow pulp wastewater under anaerobic conditions for 10-15 days for natural fermentation, ferment treatment until the pH value is below 3, and then filter the fermented wastewater with a 150-200 mesh filter to obtain clarification filtrate;

[0047] 2) Pack the column with polyamine-based weakly basic ion-exchange resin, pass the clarified filtrate through the column, and collect the column liquid; wherein, the volume ratio of the polyamine-based weakly basic ion-exchange resin to the clarified filtrate is 1:7 ;Flow rate: pass 0.5mL of clarified filtrate per gram of polyamine-based weakly basic ion exchange resin per minute, the exchange capacity is 1:6; then, add 1:8 dilution of hydrochloric acid, the amount is 2 times the amount of resin, soak for 10~ For 20 minutes, wash with 6-8 times the amount of resin in deionized water; neutralize the...

Embodiment 2

[0052] Example 1

[0053] A method for the treatment of cornstarch yellow slurry wastewater, comprising the following steps:

[0054] 1) Insert lactic acid bacteria (Lactobacillus bulgaricus or Streptococcus thermophilus) into cornstarch yellow slurry wastewater under anaerobic conditions, the temperature is normal temperature, and the fermentation time is 3 to 5 days. The waste water after fermentation treatment is filtered with a 150-200-mesh filter screen to obtain a clarified filtrate;

[0055] 2) Pack the column with polyamine-based weakly basic ion-exchange resin, pass the clarified filtrate through the column, and collect the column liquid; wherein, the column volume ratio of the polyamine-based weakly basic ion-exchange resin to the clarified filtrate is 1:7.5 ;Flow rate: pass 0.8mL of clarified filtrate per gram of polyamine-based weakly basic ion exchange resin per minute, and the exchange capacity is 1:7; then, add 1:8 dilution of hydrochloric acid, the amount is 2...

Embodiment 3

[0060] A method for the treatment of cornstarch yellow slurry wastewater, comprising the following steps:

[0061] 1) Introduce cornstarch yellow pulp wastewater into lactic acid bacteria (Lactobacillus bulgaricus or Streptococcus thermophilus) under anaerobic conditions, the temperature is 40-44°C, the fermentation time is 1-2 days, and the fermentation process is carried out until the pH value is below 3 , and then filter the waste water after fermentation treatment with a filter screen of 150 to 200 meshes to obtain a clarified filtrate;

[0062] 2) Pack the column with polyamine-based weakly basic ion-exchange resin, pass the clarified filtrate through the column, and collect the column liquid; wherein, the column volume ratio of the polyamine-based weakly basic ion-exchange resin to the clarified filtrate is 1:7.5 ;Flow rate: pass 0.8mL of clarified filtrate per gram of polyamine-based weakly basic ion exchange resin per minute, and the exchange capacity is 1:7; then, add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com