Numerical control yarn cutting machine

A cutting machine and sand wire technology, which is applied in the manufacturing field of CNC sand wire cutting machine, can solve the problems of inability to process non-metallic materials with geometric shapes, and achieve the effect of convenient operation, convenient operation and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

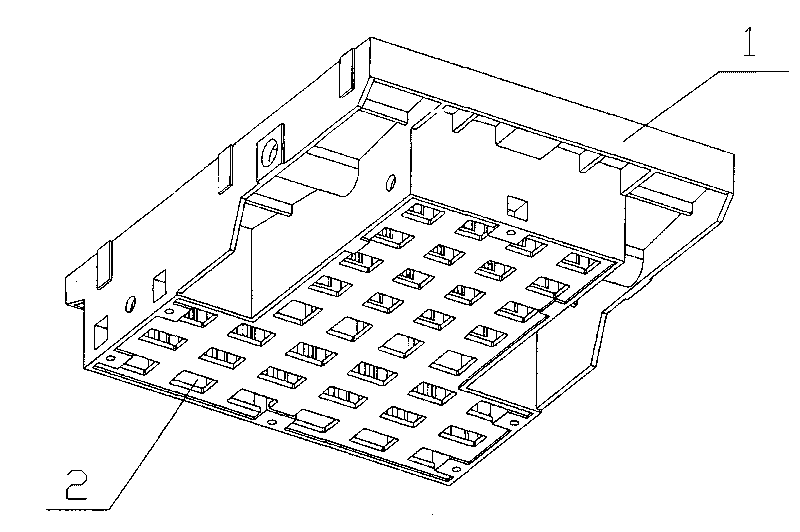

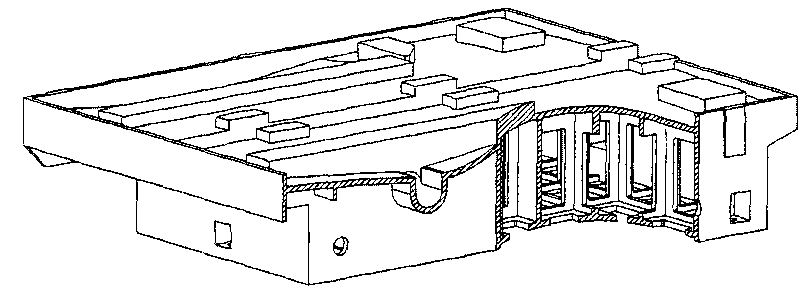

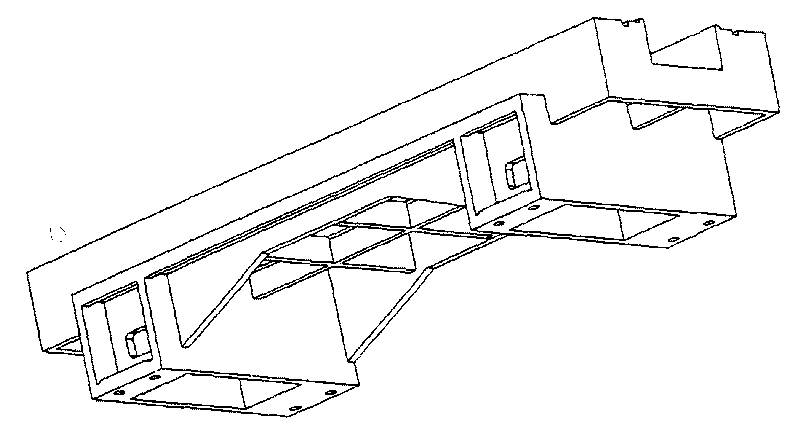

[0017] Embodiment 1. First install the base of the sand wire cutting machine on the cement floor that has been horizontally calibrated, then install the bed of the sand wire cutting machine on the base, and then install the guide rails and the work of the sand wire cutting machine on the bed. Then install the transmission device of the sand wire cutting machine and the casing of the sand wire cutting machine, and install the sliding door, air duct and numerical control device of the sand wire cutting machine on the casing. In this way, the installation of a sand wire cutting machine is completed. Before processing the workpiece, first install the workpiece (such as graphite) on the workbench of the sand wire cutting machine, then program the processing program on the numerical control device, turn on the sand wire cutting machine, and the machine performs cutting according to the pre-programmed program ( The sand line reciprocates for cutting and processing), and the designed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com