Environment-friendly flame-retardant paint for interior wall and preparation method thereof

A kind of flame-retardant coating and environmental protection technology, which is applied in the field of environmentally friendly flame-retardant coatings for interior walls and its preparation, can solve the problems of slow drying speed of water-based coatings, aggravation of fire and difficulty of rescue, and heavy smell of solvent-based coatings, so as to speed up the drying speed , Improved impact resistance and excellent aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

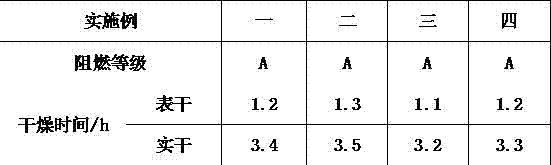

Examples

Embodiment 1

[0021] The present invention proposes an environmentally friendly flame-retardant coating for interior walls, comprising the following raw materials in parts by weight: 55 parts of water-based epoxy resin, 46 parts of water-based acrylic resin, 8 parts of xanthan gum, 16 parts of gelatin, and a particle size of 1000 mesh ultrafine 15 parts of silicon dioxide, 4 parts of sodium dodecylbenzene sulfonate, 3 parts of ammonium sulfonate, 2 parts of ammonium polyphosphate with a degree of polymerization of 10, 3 parts of melamine phosphate, 4 parts of coloring agent, resorcinol mono 0.4 parts of benzoate, 2 parts of anti-settling agent, 0.4 parts of stabilizer, 22 parts of ethanol, 51 parts of water.

[0022] Its preparation method comprises the following steps:

[0023] S1: Grind the corresponding weight parts of water-based epoxy resin and water-based acrylic resin into powder and put them in the mixer. At the same time, raise the temperature of the mixer to 60°C, and wait for 70%...

Embodiment 2

[0028] An environmentally friendly flame-retardant coating for interior walls proposed by the present invention comprises the following raw materials in parts by weight: 60 parts of water-based epoxy resin, 40 parts of water-based acrylic resin, 10 parts of xanthan gum, 12 parts of gelatin, and the particle size is 3000 mesh ultrafine 10 parts of silicon dioxide, 2 parts of sodium dodecylbenzene sulfonate, 4 parts of ammonium sulfonate, 2 parts of ammonium polyphosphate with a degree of polymerization of 20, 4 parts of melamine phosphate, 5 parts of colorant, 2-(2' -Hydroxy-3',5'-di-tert-butylphenyl)-5-chlorobenzotriazole 0.6 parts, anti-settling agent 2 parts, stabilizer 0.4 parts, ethanol 26 parts, water 60 parts.

[0029] Its preparation method comprises the following steps:

[0030] S1: Grind the corresponding weight parts of water-based epoxy resin and water-based acrylic resin into powder and put them in the mixer, and raise the temperature of the mixer to 50°C at the sa...

Embodiment 3

[0035]The present invention proposes an environmentally friendly flame-retardant coating for interior walls, comprising the following raw materials in parts by weight: 46 parts of water-based epoxy resin, 36 parts of water-based acrylic resin, 12 parts of xanthan gum, 10 parts of gelatin, and a particle size of 300 mesh ultrafine 15 parts of silicon dioxide, 6 parts of sodium dodecylbenzene sulfonate, 4 parts of ammonium sulfonate, 3 parts of ammonium polyphosphate with a degree of polymerization of 18, 4 parts of melamine phosphate, 3 parts of coloring agent, 2-hydroxy-4 - 0.2 parts of methoxy-5-sulfonic acid benzophenone, 2 parts of anti-settling agent, 0.5 parts of stabilizer, 26 parts of ethanol, and 44 parts of water.

[0036] Its preparation method comprises the following steps:

[0037] S1: Grind corresponding weight parts of water-based epoxy resin and water-based acrylic resin into powder and place them in a mixer, while raising the temperature of the mixer to 55°C, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com