Production process of inorganic modified polyphenyl granule incombustilble heat insulation plate

A technology of polystyrene particles and inorganic modification, applied in thermal insulation, building components, etc., can solve problems such as poor fire resistance, achieve the effects of improving compression resistance, low production cost, promoting carbonization and smoke suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

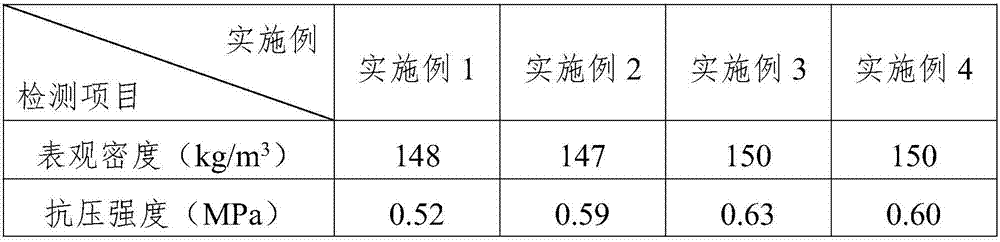

Examples

Embodiment 1

[0027] A production process of inorganic modified polystyrene particle non-combustible insulation board, comprising the following steps:

[0028] (1) Add magnesium oxide powder with a particle size of 30-40 μm to the magnesium chloride solution, stir evenly at room temperature, then add polystyrene particles, open-cell expanded perlite with a particle size of 2-4 mm, and open-cell expanded perlite with a particle size of 0.5-1.5 mm mm of closed-cell expanded perlite, reinforcing fiber, aluminum hydroxide and water glass, stirred at room temperature for 25 minutes;

[0029] (2) Add polyvinyl acetate emulsion, dimethyl methyl phosphate and trichloroethyl phosphate to the above system, stir at room temperature for 15 min, and the stirring speed is 160 r / min;

[0030] (3) Pour the above-mentioned mixture into a mould, press and form it with a roller at room temperature, control the forming pressure to 0.02MPa, and press for 4s, and then lay the mesh cloth on the surface of the bot...

Embodiment 2

[0034] A production process of inorganic modified polystyrene particle non-combustible insulation board, comprising the following steps:

[0035] (1) Add magnesium oxide powder with a particle size of 30-40 μm to the magnesium chloride solution, stir evenly at room temperature, then add polystyrene particles, open-cell expanded perlite with a particle size of 2-4 mm, and open-cell expanded perlite with a particle size of 0.5-1.5 mm mm of closed-cell expanded perlite, reinforcing fiber, aluminum hydroxide and water glass, stirred at room temperature for 20 minutes;

[0036] (2) Add polyvinyl acetate emulsion, dimethyl methyl phosphate and trichloroethyl phosphate to the above system, stir at room temperature for 10 min, and the stirring speed is 100 r / min;

[0037] (3) Pour the above-mentioned mixture into a mould, press and form with rollers at normal temperature, control the forming pressure to 0.01MPa, and press for 2s, and then lay the grid cloth on the surface of the botto...

Embodiment 3

[0041] A production process of inorganic modified polystyrene particle non-combustible insulation board, comprising the following steps:

[0042] (1) Add magnesium oxide powder with a particle size of 30-40 μm to the magnesium chloride solution, stir evenly at room temperature, then add polystyrene particles, open-cell expanded perlite with a particle size of 2-4 mm, and open-cell expanded perlite with a particle size of 0.5-1.5 mm mm of closed-cell expanded perlite, reinforcing fiber, aluminum hydroxide and water glass, stirred at room temperature for 30 minutes;

[0043] (2) Add polyvinyl acetate emulsion, dimethyl methyl phosphate and trichloroethyl phosphate to the above system, stir at room temperature for 20min, and the stirring speed is 200r / min;

[0044] (3) Pour the above-mentioned mixture into a mould, press and form it with a roller at room temperature, control the forming pressure to 0.04MPa, and press for 5s, and then lay the grid cloth on the surface of the botto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com