Additional organosilicon fireproof pouring sealant for electronics and preparation method thereof

A technology of silicone and potting glue, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of finished product performance, storage and mechanical properties, personnel hazards, environmental pollution, etc., to achieve a wide range of applicable temperatures , Increase the amount of addition, the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

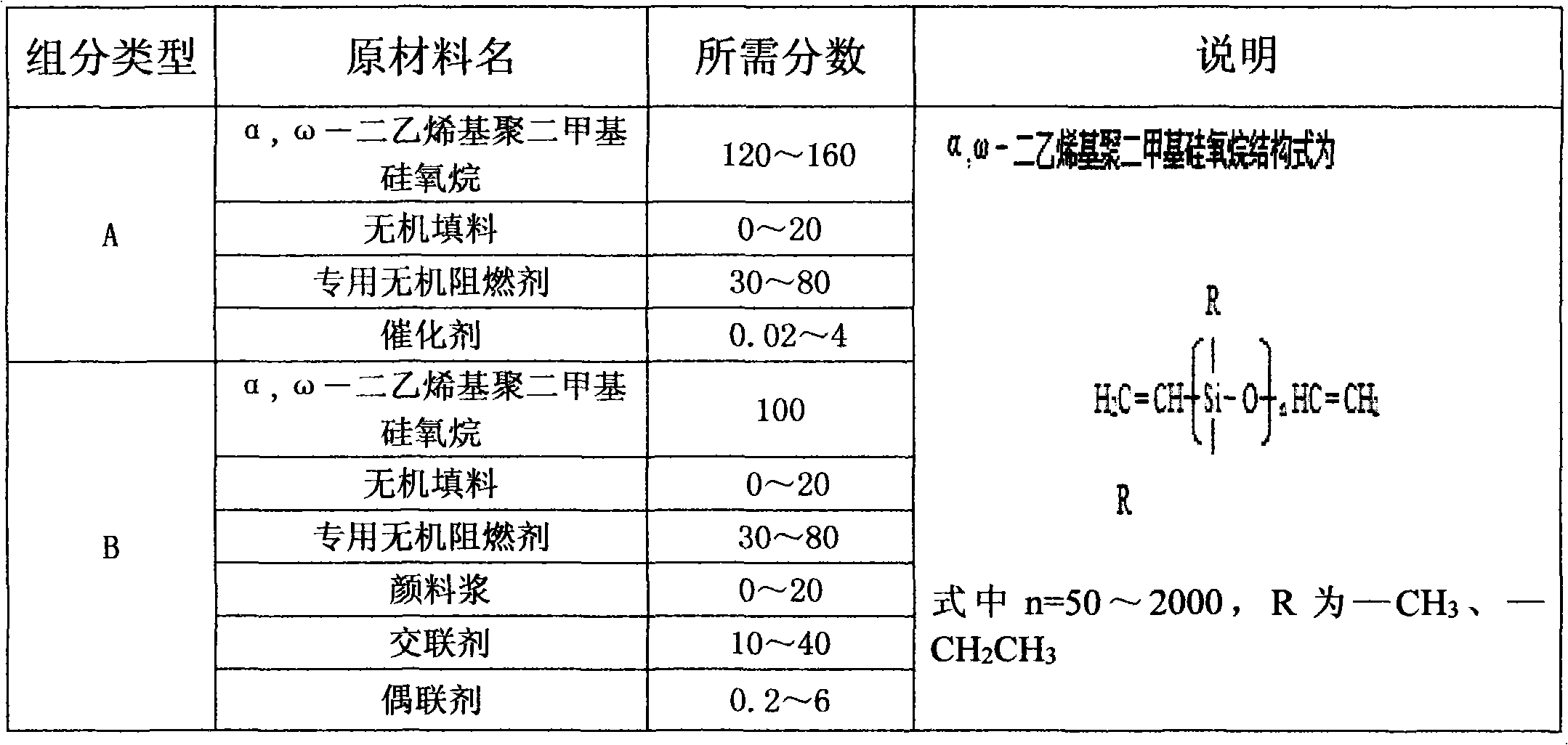

Method used

Image

Examples

Embodiment 1

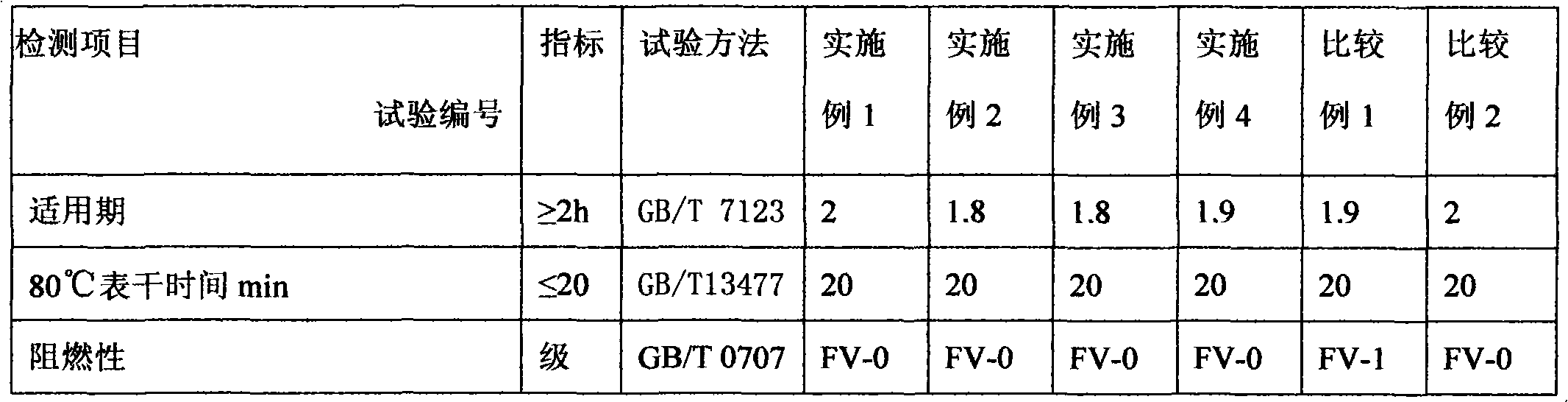

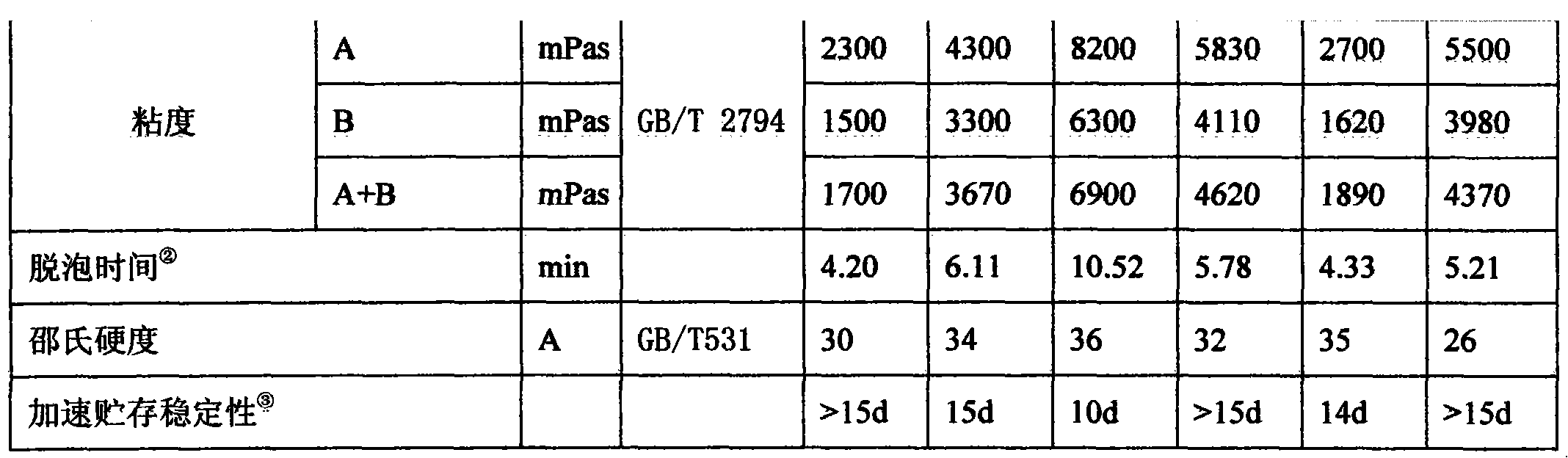

[0013] 100 parts of α, ω-divinyl polydimethylsiloxane with a viscosity of 500 mPas at 25±2°C, special ① Put 80 parts of aluminum hydroxide into a kneader and knead for 3 hours at a temperature of 180° C. and a vacuum of -0.08 MPa, and cool to obtain a base material. At room temperature, add 100 parts of base material, 20 parts of α, ω-divinylpolydimethylsiloxane, and 0.2 parts of platinum catalyst into the planetary mixer, keep the vacuum degree -0.08MPa, stir at 70rpm, and stir for 20 Minutes to prepare component A; at room temperature, add 100 parts of base material, 1 part of carbon black pigment slurry, 12 parts of hydrogen-containing silicone oil at the end, and 0.5 parts of vinyltrimethoxysilane into the planetary mixer, and keep the vacuum degree -0.08 MPa, the stirring speed is 70rpm, stirring for 20 minutes to prepare the B component. The product performance test results are shown in Table 1.

Embodiment 2

[0015] Put 100 parts of α, ω-divinyl polydimethylsiloxane with a viscosity of 500 mPas at 25±2°C and 80 parts of aluminum hydroxide into a kneader and knead at a temperature of 180°C and a vacuum of -0.08MPa After 3 hours, the base material was obtained after cooling. At room temperature, add 100 parts of base material, 20 parts of α, ω-divinylpolydimethylsiloxane, and 0.2 parts of platinum catalyst into the planetary mixer, keep the vacuum degree -0.08MPa, stir at 70rpm, and stir for 20 Minutes to prepare component A; at room temperature, add 100 parts of base material, 1 part of carbon black pigment slurry, 12 parts of terminal hydrogen-containing silicone oil crosslinking agent, and 0.5 part of vinyltrimethoxysilane coupling agent into the planetary mixer , keep the vacuum degree -0.08MPa, stir at 70rpm, stir for 20 minutes, and get B component. The product performance test results are shown in Table 1.

Embodiment 3

[0017] Put 100 parts of α, ω-divinyl polydimethylsiloxane with a viscosity of 500 mPas at 25±2°C and 75 parts of magnesium hydroxide into a kneader at a temperature of 180°C and a vacuum of -0.08MPa After kneading for 3 hours, the base material was obtained after cooling. At room temperature, add 100 parts of base material, 20 parts of α, ω-divinylpolydimethylsiloxane, and 0.2 parts of platinum catalyst into the planetary mixer, keep the vacuum degree -0.08MPa, stir at 70rpm, and stir for 20 Minutes to prepare component A; at room temperature, add 100 parts of base material, 1 part of carbon black pigment slurry, 12 parts of hydrogen-containing silicone oil at the end, and 0.5 parts of vinyltrimethoxysilane into the planetary mixer, and keep the vacuum degree -0.08 MPa, the stirring speed is 70rpm, stirring for 20 minutes to prepare the B component. The product performance test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com