A manufacturing process of automobile insert damping block

A manufacturing process and technology of damping blocks, applied in the direction of coating, etc., can solve the problems that silica gel and stainless steel are difficult to bond firmly, small and medium-sized enterprises cannot bear equipment, environment and human hazards, etc., and achieve small changes in hardness and high tensile strength , high heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A manufacturing process of an automobile insert damping block comprises the following steps:

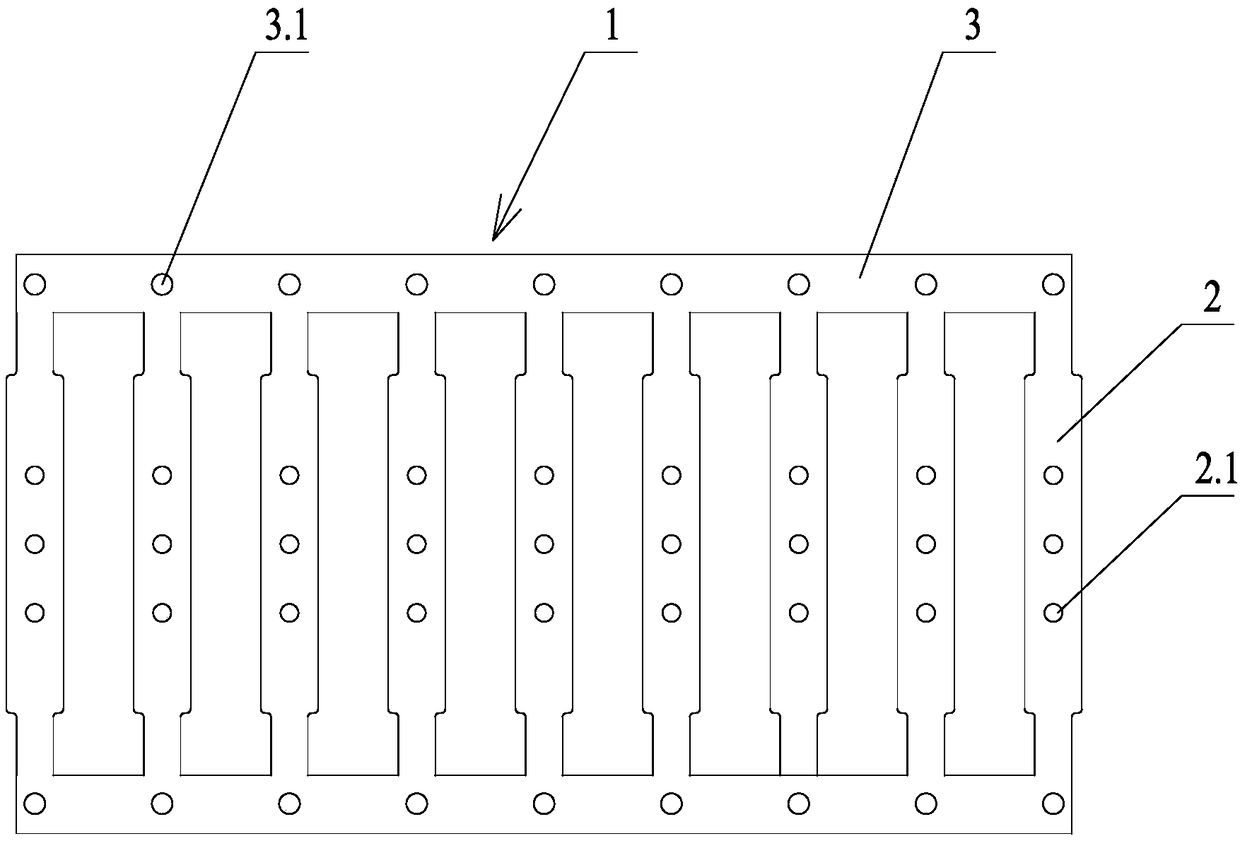

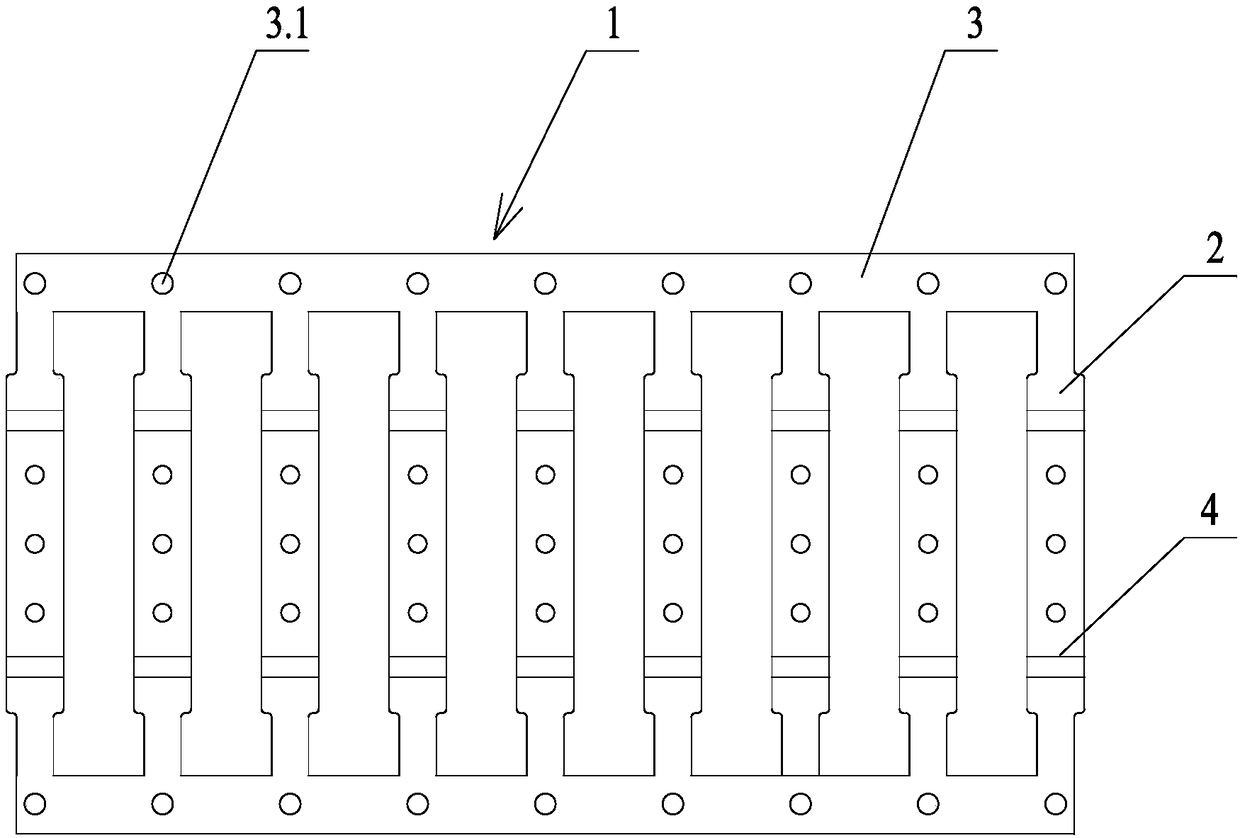

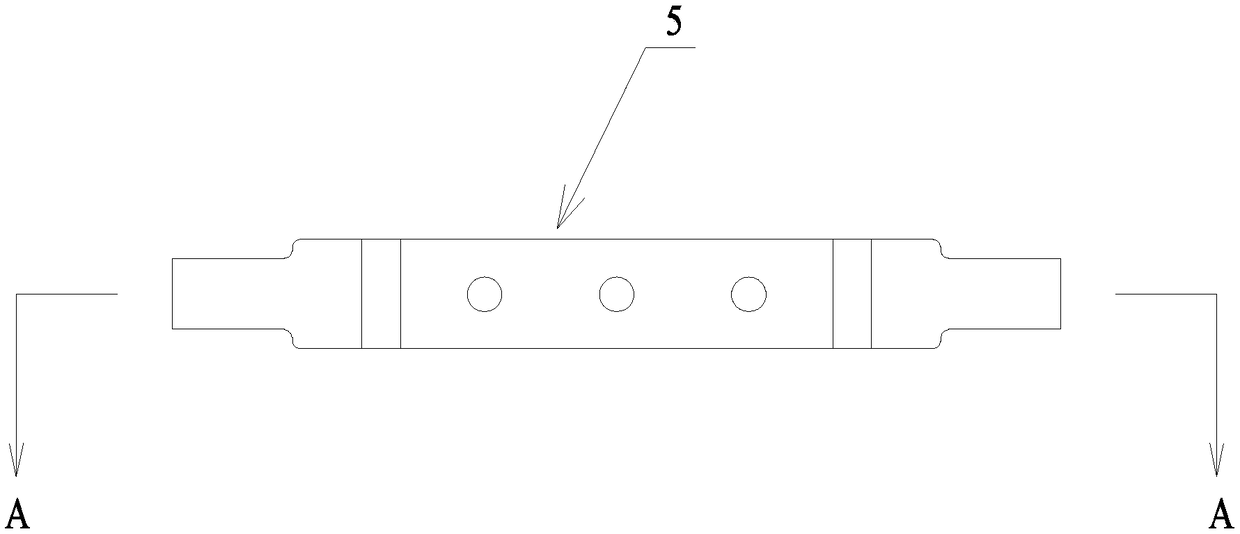

[0024] a. Take the pre-produced stainless steel skeleton sheet 1 for the damping block whose material type is 301, and reserve it; the stainless steel skeleton sheet 1 for the damping block includes the stainless steel skeleton unit plate 2 and the connecting plate 3 for the damping block, and the upper and lower two pieces are parallel The stainless steel skeleton unit plates 2 for damping blocks are fixed at intervals between the connecting plates 3, and positioning holes 3.1 are opened on the connecting plates 3 corresponding to the two ends of the stainless steel skeleton unit plates 2 for each damping block. A fixing hole 2.1 is provided in the middle of the stainless steel skeleton unit plate 2 for the damping block;

[0025] b. Remove the oil stain on the surface of the stainless steel skeleton sheet 1 for the damping block;

[0026] c. Soak the damping block in 10% H ...

Embodiment 2

[0037] A manufacturing process of an automobile insert damping block comprises the following steps:

[0038] a. Take the pre-produced stainless steel skeleton sheet 1 for the damping block and set it aside; the stainless steel skeleton sheet 1 for the damping block includes the stainless steel skeleton unit plate 2 for the damping block and the connection plate 3, and the upper and lower two connection plates 3 are arranged in parallel There are stainless steel skeleton unit plates 2 for damping blocks fixed at intervals, and positioning holes 3.1 are opened on the connecting plates 3 corresponding to the two ends of the stainless steel skeleton unit plates 2 for each damping block. A fixing hole 2.1 is opened in the middle of the unit plate 2;

[0039] b. Use acetone solution to degrease the damping block with stainless steel skeleton sheet 1 first, and then use absolute ethanol to remove the acetone solution remaining on the surface of the damping block stainless steel skele...

Embodiment 3

[0051] A manufacturing process of an automobile insert damping block comprises the following steps:

[0052] a. Take the pre-produced stainless steel skeleton sheet 1 for the damping block and set it aside; the stainless steel skeleton sheet 1 for the damping block includes the stainless steel skeleton unit plate 2 for the damping block and the connection plate 3, and the upper and lower two connection plates 3 are arranged in parallel There are stainless steel skeleton unit plates 2 for damping blocks fixed at intervals, and positioning holes 3.1 are opened on the connecting plates 3 corresponding to the two ends of the stainless steel skeleton unit plates 2 for each damping block. A fixing hole 2.1 is opened in the middle of the unit plate 2;

[0053] b. Use acetone solution to degrease the damping block with stainless steel skeleton sheet 1 first, and then use absolute ethanol to remove the acetone solution remaining on the surface of the damping block stainless steel skele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com