Preparation method of recyclable cellulose paper base nano-silver catalyst materials and application of materials

A catalytic material and cellulose technology, applied in the field of nanomaterials, can solve the problems of low mechanical strength of cellulose paper-based materials, easy disintegration of porous paper-based macrostructures, and catalyst falling off, and achieves good reusability and reduction method. Simple, enhanced interaction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the recyclable cellulose paper-based nano-silver catalytic material, the steps are as follows:

[0033] (1) Surface functionalization of cellulose paper-based materials: Dissolve the silane coupling agent in the ethanol / water system, stir and disperse to obtain a silane coupling agent solution, and immerse the cellulose paper-based material into the silane coupling agent solution , react for 1-4 hours, take out the cellulose paper-based material after the reaction, place it in an oven at 110-130°C for activation for 2-4 hours, wash the activated cellulose paper-based material with water and ethanol, and dry at room temperature. Obtain the cellulose paper-based material I with surface amino functionalization;

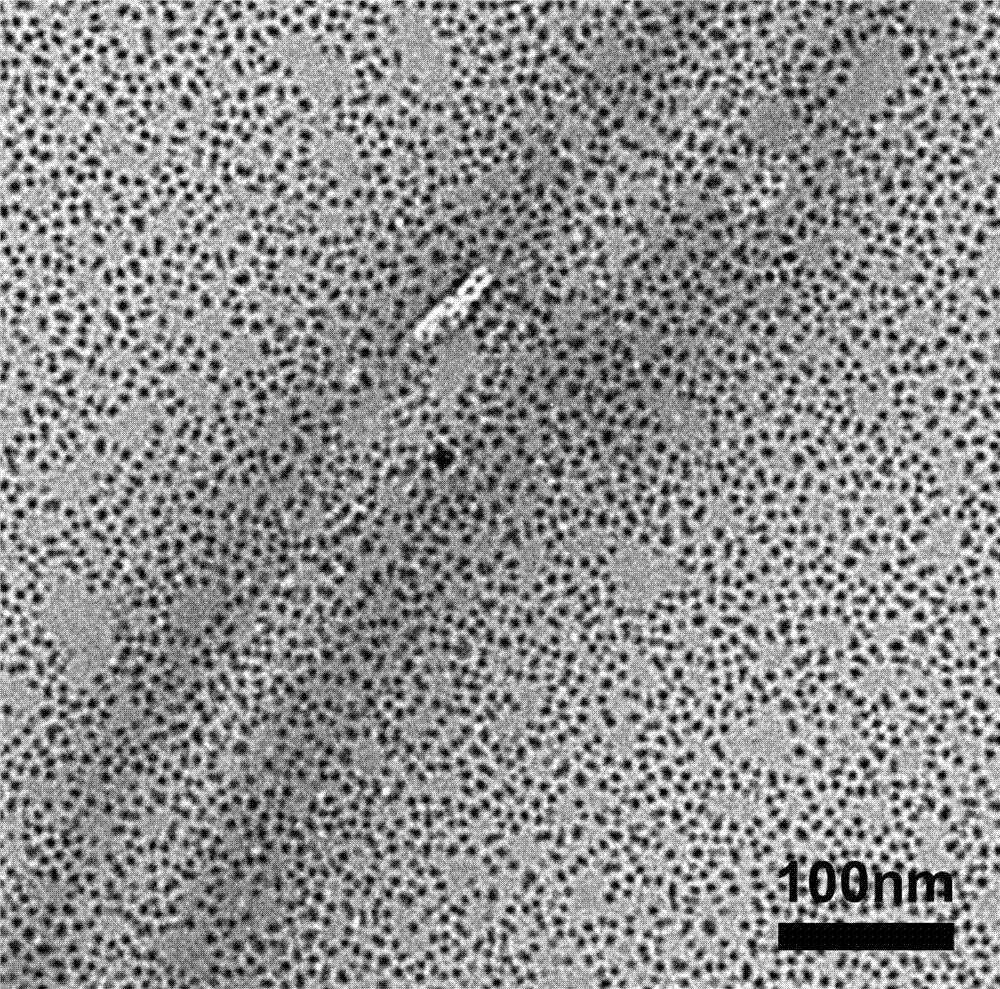

[0034] (2) Adsorption of silver nano-precursor ions: immerse the cellulose paper base material I in the silver nano-precursor solution, incubate at a constant temperature of 25-40°C for 0.5-2 hours, and then wash with water to remove excess...

Embodiment 1

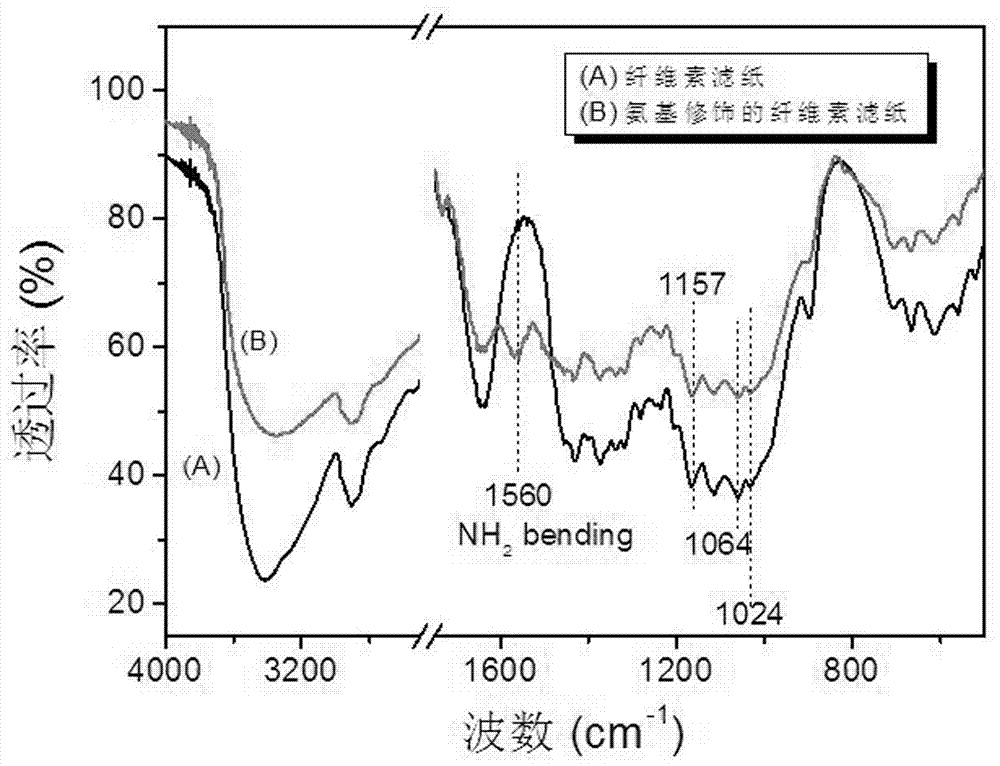

[0048] 1. Surface functionalization of cellulose paper: using ordinary cellulose filter paper (CFP) in the laboratory as the carrier of silver nanomaterials, using silane coupling reagents to modify the surface with amino groups to enhance its ability to chelate and adsorb metal ions .

[0049] Dissolve 40mg of 3-aminopropyltrimethoxysilane in 100mL of ethanol / water system (70 / 30, v / v), and stir to disperse; take cellulose paper-based laboratory filter paper, and cut it into suitable The size of the rectangle, immersed in the above system, reacted for 4 hours.

[0050] Take out the cellulose filter paper and place it in an oven at 130 °C for 4 hours to activate the hydroxyl groups on the surface of the cellulose to form amino groups; wash the activated filter paper with water and ethanol respectively, and vacuum-dry at room temperature to obtain the cellulose filter paper with surface amino functionalization.

[0051] 2. Surface functionalized paper chelates and adsorbs metal...

Embodiment 2

[0059] 1. Surface functionalization of cellulose paper: use laboratory printing paper as the carrier of silver nanomaterials, and use silane coupling reagents to modify the surface with amino groups to enhance its ability to chelate and adsorb metal ions.

[0060] Dissolve 250mg of 3-aminopropyltriethoxysilane in 100mL of ethanol / water system (70 / 30, v / v), and stir to disperse; take printing paper and cut it into a circle of suitable size, immerse in In the above system, react for 2.5 hours.

[0061] Take out the printing paper and place it in an oven at 110°C for 2 hours to activate the surface hydroxyl group of the cellulose on the printing paper to form an amino group; wash the activated printing paper with water and ethanol respectively, and dry it in vacuum at room temperature to obtain the cellulose with amino functionalized surface printer paper.

[0062] 2. Surface functionalized paper chelates and adsorbs metal precursor ions: the chelation between the lone pair of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com