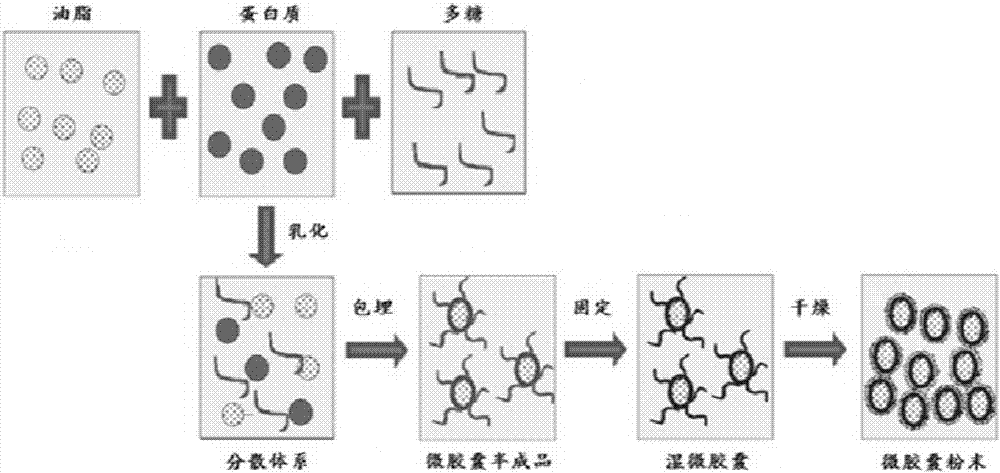

Single-core edible oil and fat microcapsules and preparation method thereof

A technology of edible oils and microcapsules, which is applied in the fields of application, food science, food composition, etc., can solve the problems of uniform size and wall thickness, lack of microcapsule shape and size, and inability to obtain structure, etc., to achieve high universality , enhance protection, increase the effect of wall material layer thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

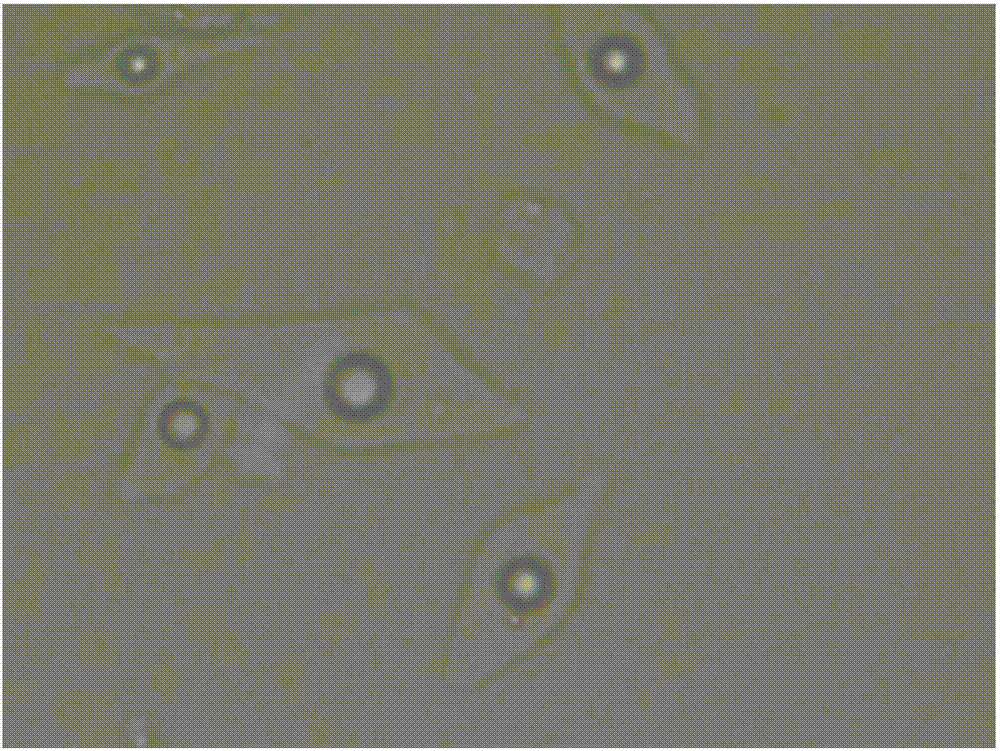

[0073] Preparation of microcapsules by embedding methyl linoleate (medium wall thickness microcapsule product)

[0074] 1) Dissolve 5% (w / w) gelatin and 5% (w / w) gum arabic under stirring at 55°C, add 0.05% (w / v) Tween 80 into the gelatin solution, dissolve The process lasts for 60 minutes to ensure sufficient and complete hydration;

[0075] 2) 5% (w / w) gelatin solution and 10% methyl linoleate (w / w) were vortexed in a 50mL centrifuge tube for 15s for pre-emulsification, transferred to a syringe connected to a 10μm SPG membrane emulsifier, and used The syringe pump is used for bolus injection at a rate of 25mL / min, and the membrane is repeatedly passed through the membrane 3 times;

[0076] 3) Stir and mix the emulsion and gum arabic solution in a constant temperature container at 45°C, add water to dilute the system to the required concentration, adjust the system to the target stirring speed, and ensure that stirring at this speed is maintained until the preparation of mic...

Embodiment 2

[0081] Preparation of microcapsules by embedding methyl linolenate (thicker wall thickness microcapsule products)

[0082] 1) Dissolve 5% (w / w) gelatin and 5% (w / w) gum arabic under stirring at 55°C, add 0.05% (w / v) Tween 80 into the gelatin solution, dissolve The process lasts for 60 minutes to ensure sufficient and complete hydration;

[0083] 2) 5% (w / w) gelatin solution and 5% methyl linolenate (w / w) were pre-emulsified in a 50mL centrifuge tube by vortexing for 15s, transferred to a syringe connected with a 10μm SPG membrane emulsifier, using a syringe pump Carry out bolus injection at a speed of 25mL / min, and pass through the membrane repeatedly 3 times;

[0084] 3) Stir and mix the emulsion and gum arabic solution in a constant temperature container at 45°C, add water to dilute the system to the required concentration, adjust the system to the target stirring speed, and ensure that stirring at this speed is maintained until the preparation of microcapsules is completed...

Embodiment 3

[0089] Preparation of microcapsules by embedding methyl oleate (microcapsule products with thinner wall thickness)

[0090] 1) Dissolve 5% (w / w) gelatin and 5% (w / w) gum arabic under stirring at 55°C, add 0.05% (w / v) Tween 80 into the gelatin solution, dissolve The process lasts for 60 minutes to ensure sufficient and complete hydration;

[0091] 2) 5% (w / w) gelatin solution and 20% methyl oleate (w / w) were vortexed in a 50mL centrifuge tube for 15s for pre-emulsification, transferred to a syringe connected with a 10μm SPG membrane emulsifier, using a syringe pump Carry out bolus injection at a speed of 25mL / min, and pass through the membrane repeatedly 3 times;

[0092] 3) Stir and mix the emulsion and gum arabic solution in a constant temperature container at 45°C, add water to dilute the system to the required concentration, adjust the system to the target stirring speed, and ensure that stirring at this speed is maintained until the preparation of microcapsules is complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com