Tungsten trioxide/tungsten dioxide composite material capable of being used as negative electrode of lithium ion battery and preparation method of tungsten trioxide/tungsten dioxide composite material

A lithium-ion battery and tungsten trioxide technology, applied in battery electrodes, secondary batteries, electrochemical generators, etc., can solve the problem of losing electronic contact between active materials and current collectors, destroying the stability of electrode materials, and reducing electrode cycle performance and other issues, to achieve the effect of reducing volume change, reducing charge transfer resistance, and improving discharge specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

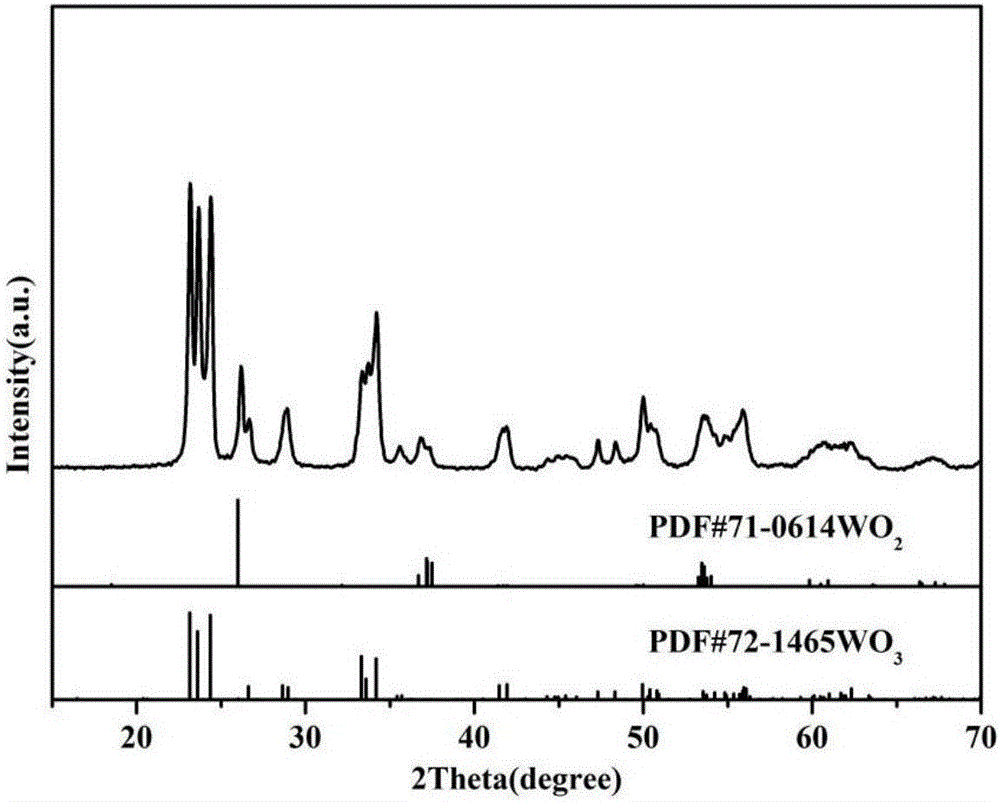

Image

Examples

Embodiment 1

[0030] 1) Prepare 0.5M C 6 h 8 o 7 ·H 2 O in distilled water, 0.5 M Na 2 WO 4 2H 2 O distilled water.

[0031] 2) Dilute the above solution by volume ratio C 6 h 8 o 7 ·H 2 O:Na 2 WO 4 2H 2 Mix at a ratio of O=2:1, and stir at 25°C for 15 minutes.

[0032] 3) Adjust the pH of the above mixed solution to 1 with a 2M HCl solution.

[0033] 4) Pour the homogeneously mixed solution into a polytetrafluoroethylene-lined high-pressure hydrothermal reactor, keeping the volume filling ratio at 40%.

[0034] 5) Put the sealed reaction kettle into the homogeneous hydrothermal reactor, set the temperature parameter to 160° C., and the reaction time to 28 hours.

[0035] 6) Cool to room temperature after the reaction, centrifuge the final reactant, and wash with deionized water and absolute ethanol three times respectively. Put the centrifuged and washed powder in a vacuum oven at 60°C for 10 hours to obtain the final product.

[0036] The Coulombic efficiency can reach 95...

Embodiment 2

[0039] 1) Prepare 1M of C 6 h 8 o 7 ·H 2 O in distilled water, 1M Na 2 WO 4 2H2 O distilled water.

[0040] 2) Dilute the above solution by volume ratio C 6 h 8 o 7 ·H 2 O:Na 2 WO 4 2H 2 O=1:1 ratio mixed, stirred at 35°C for 35min.

[0041] 3) Adjust the pH of the above mixed solution to 3 with a 3M HCl solution.

[0042] 4) Pour the homogeneously mixed solution into a polytetrafluoroethylene-lined high-pressure hydrothermal reactor, keeping the volume filling ratio at 60%.

[0043] 5) Put the sealed reactor into the homogeneous hydrothermal reactor, set the temperature parameter to 200° C., and the reaction time to 20 h.

[0044] 6) Cool to room temperature after the reaction, centrifuge the final reactant, and wash with deionized water and absolute ethanol three times respectively. Put the centrifuged and washed powder into a vacuum oven at 80°C for 5 hours to dry to obtain the final product.

[0045] The Coulombic efficiency can reach 92% after 500 cycles a...

Embodiment 3

[0047] 1) Prepare 0.8M C 6 h 8 o 7 ·H 2 O in distilled water, 0.8 M Na 2 WO 4 2H 2 O distilled water.

[0048] 2) Dilute the above solution by volume ratio C 6 h 8 o 7 ·H 2 O:Na 2 WO 4 2H 2 Mix at a ratio of O=3:1, and stir at 30°C for 25 minutes.

[0049] 3) Adjust the pH of the above mixed solution to 2 with a 2M HCl solution.

[0050] 4) Pour the homogeneously mixed solution into a polytetrafluoroethylene-lined high-pressure hydrothermal reactor, keeping the volume filling ratio at 50%.

[0051] 5) Put the sealed reactor into a homogeneous hydrothermal reactor, set the temperature parameter to 180° C., and the reaction time to 24 hours.

[0052] 6) Cool to room temperature after the reaction, centrifuge the final reactant, and wash with deionized water and absolute ethanol three times respectively. The final product is obtained by putting the centrifuged and washed powder into a vacuum oven or a freeze drying oven at 70° C. for 8 hours to dry.

[0053] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com