Technology for extracting phosphoesterase by ion exchange resin

A technology of ion exchange resin and phosphatase, which is applied in the direction of enzyme, hydrolase, glycosylase, etc., can solve the problems of many times, long medication cycle, poor patient compliance, etc., achieve simple process, improve compliance, reduce The effect of product price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

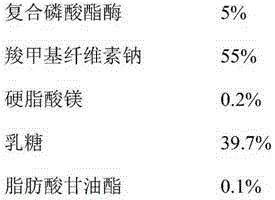

[0013] A kind of ion exchange resin extracts the component and the weight ratio of phosphatase process:

[0014]

[0015] A kind of preparation method of ion exchange resin extraction phosphatase process, concrete steps comprise:

[0016] ①Material preparation, preparation according to the weight ratio of each component of a compound phosphatase sustained-release tablet, the compound phosphatase is crushed at low temperature and passed through a 120-mesh sieve, and the pharmaceutical excipients are respectively crushed through a 80-mesh sieve.

[0017] ②Granulation, mix the components of the sustained-release tablet obtained in step ① evenly, and wet granulate; the process parameters are: the inlet air temperature is 40-45°C, the material temperature is 30-35°C, and the outlet air temperature is 22-26°C. ℃.

[0018] ③Sizing, crush the granules obtained in step ②, and pass through a 20-mesh sieve.

[0019] ④Compress the granules obtained in step ③ with a low-speed tablet p...

Embodiment 2

[0023] A kind of ion exchange resin extracts the component and the weight ratio of phosphatase process:

[0024]

[0025] A kind of preparation method of ion exchange resin extraction phosphatase process, concrete steps comprise:

[0026] ① Raw material preparation, according to the weight ratio of each component of a compound phosphatase sustained-release tablet, the compound phosphatase is ground at low temperature and passed through a 120-mesh sieve, and the pharmaceutical excipients are respectively crushed through a 80-mesh sieve.

[0027] ②Granulation, mix the components of the sustained-release tablet obtained in step ① evenly, and wet granulate; the process parameters are: the inlet air temperature is 40-45°C, the material temperature is 30-35°C, and the outlet air temperature is 22-26°C. ℃.

[0028] ③Sizing, crush the granules obtained in step ②, and pass through a 20-mesh sieve.

[0029] ④ Press the granules obtained in step ③ into tablets by a low-speed tablet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com