Silicon anode electrode plate for lithium ion battery and preparation method of electrode plate

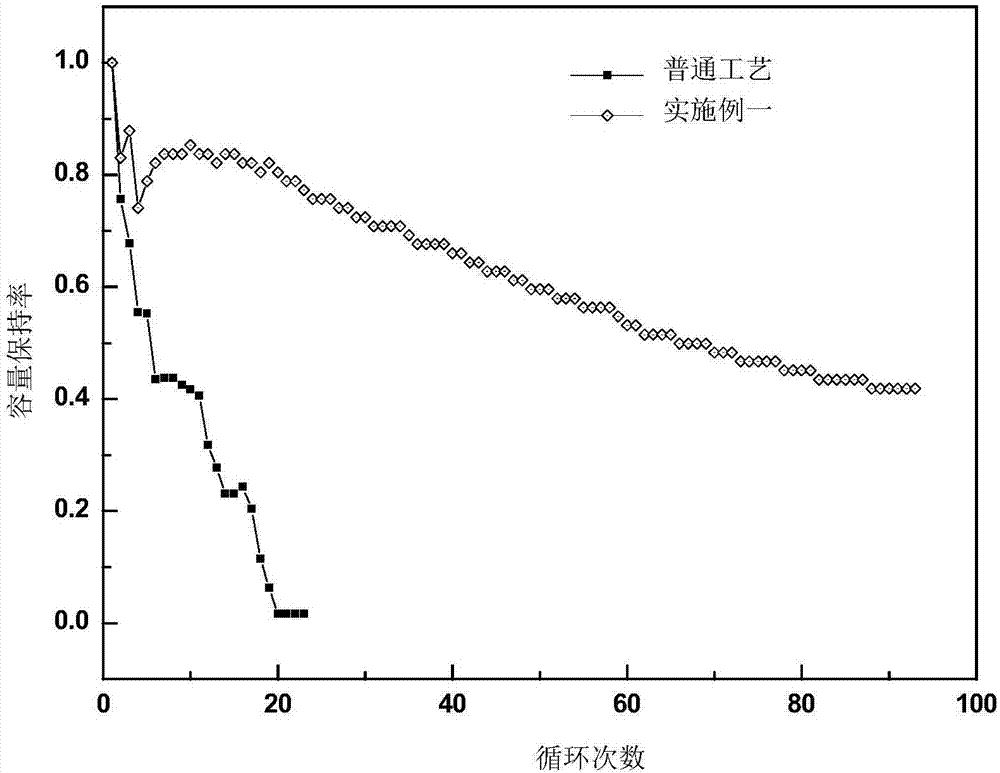

A lithium-ion battery and electrode sheet technology, applied in battery electrodes, electrode manufacturing, electrode rolling/calendering, etc., can solve problems such as the inability to fundamentally improve battery energy density and cycle life, improve battery performance, and complex technological processes , to achieve the effect of easy coating, increase energy density, and improve cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Weigh 500 grams of micro-nano-structure silicon material containing metal elements and mix and dissolve 50 grams of glucose powder in 3000 grams of deionized water, and enter the spray drying system under the condition of ultrasonic stirring to obtain about 500 grams of dry powder;

[0030] (2) Put the powder obtained in step (1) into a rotary high-temperature furnace, pass nitrogen gas for 30 minutes before heating up, and then start heating up at a rate of 5°C / min, 30min at 200°C, and then continue to heat up to 450°C at 5°C / min ℃, kept for 3 hours to allow the organic matter to be cracked into amorphous carbon and coated on the surface of the silicon material, and finally the temperature was naturally cooled to room temperature, and the obtained carbon-coated silicon material product was taken out;

[0031] (3) Mix 70 grams of the above carbon-coated silicon material with 10 grams of polyacrylic acid (PAA), 4 grams of carboxymethyl cellulose (CMC), 6 grams of cond...

Embodiment 2

[0034] (1) Weigh 500 grams of micro-nano-structure silicon material containing metal elements and mix and dissolve 50 grams of glucose powder in 3000 grams of deionized water, and enter the spray drying system under the condition of ultrasonic stirring to obtain about 500 grams of dry powder;

[0035] (2) Put the powder obtained in step (1) into a rotary high-temperature furnace, pass nitrogen gas for 30 minutes before heating up, and then start heating up at a rate of 5°C / min, 30min at 200°C, and then continue to heat up to 450°C at 5°C / min ℃, kept for 3 hours to allow the organic matter to be cracked into amorphous carbon and coated on the surface of the silicon material, and finally the temperature was naturally cooled to room temperature, and the obtained carbon-coated silicon material product was taken out;

[0036] (3) Mix 90 grams of the above carbon-coated silicon material with an aqueous solution with a solid content of 8 grams of polyacrylic acid (PAA), add 0.5 grams ...

Embodiment 3

[0039] (1) Take by weighing 500 grams of micro-nano structured silicon materials containing metal elements and 500 grams of solution containing 50 grams of phenolic resin, then add 2500 grams of deionized water and enter the spray drying system under the situation of ultrasonic stirring, and obtain a dry powder of about 500 g;

[0040] (2) Put the powder obtained in step (1) into a rotary high-temperature furnace, pass nitrogen gas for 30 minutes before heating up, and then start heating up at a rate of 5°C / min, 30 minutes at 200°C, and then continue to heat up to 750°C at 5°C / min ℃, kept for 3 hours to allow the organic matter to be cracked into amorphous carbon and coated on the surface of the silicon material, and finally the temperature was naturally cooled to room temperature, and the obtained carbon-coated silicon material product was taken out;

[0041] (3) Mix 70 grams of the above carbon-coated silicon material with 10 grams of polyacrylic acid (PAA), 4 grams of carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com