Preparation method of graphene/lithium iron phosphate composite material

A technology of lithium iron phosphate and composite materials, which is applied in the direction of phosphate, phosphorus compounds, phosphorus oxyacids, etc., can solve the problems that affect the conductivity of materials, the lack of uniformity of conductive carbonaceous materials, and the problem of graphene agglomeration is not considered. , to achieve the effect of a good conductive network

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1. Ultrasonically disperse graphite oxide in deionized water to prepare a graphene oxide suspension with a solid content of 5%;

[0021] 2. Add the graphene oxide suspension to the lithium iron phosphate precursor, control the amount of graphene oxide added to 1% of the mass fraction of the solute, add deionized water, adjust the solid content to 70%, and carry out wet ball milling, 40Hz ball milling for 4h , placed at 100°C for 24 hours in vacuum, and ground to obtain a graphene oxide / lithium iron phosphate composite material;

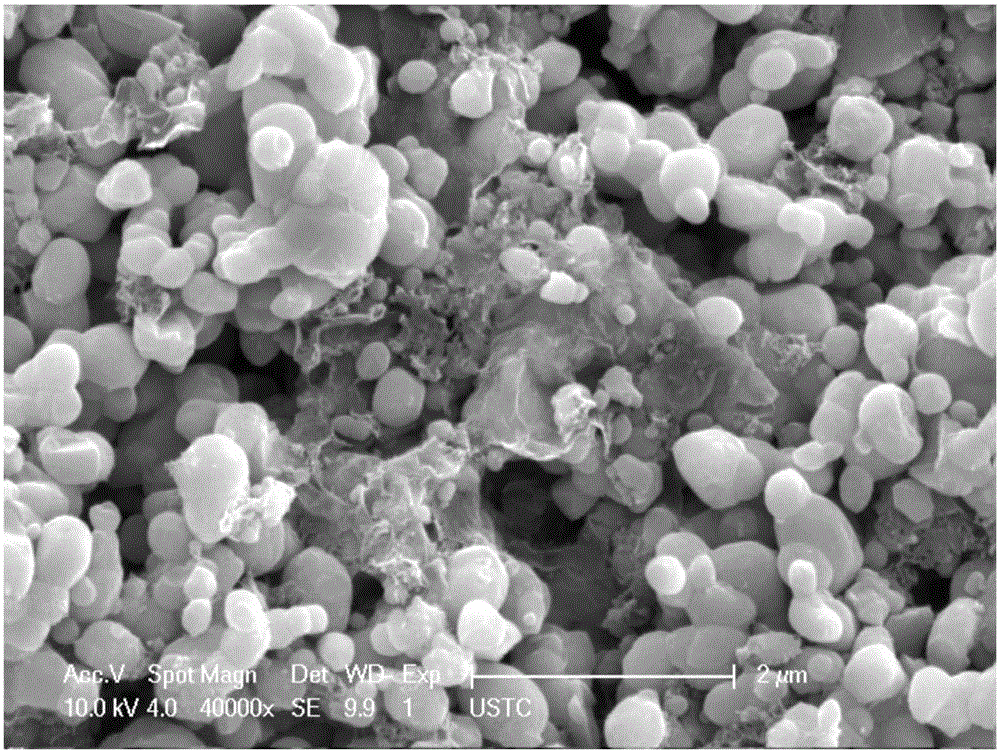

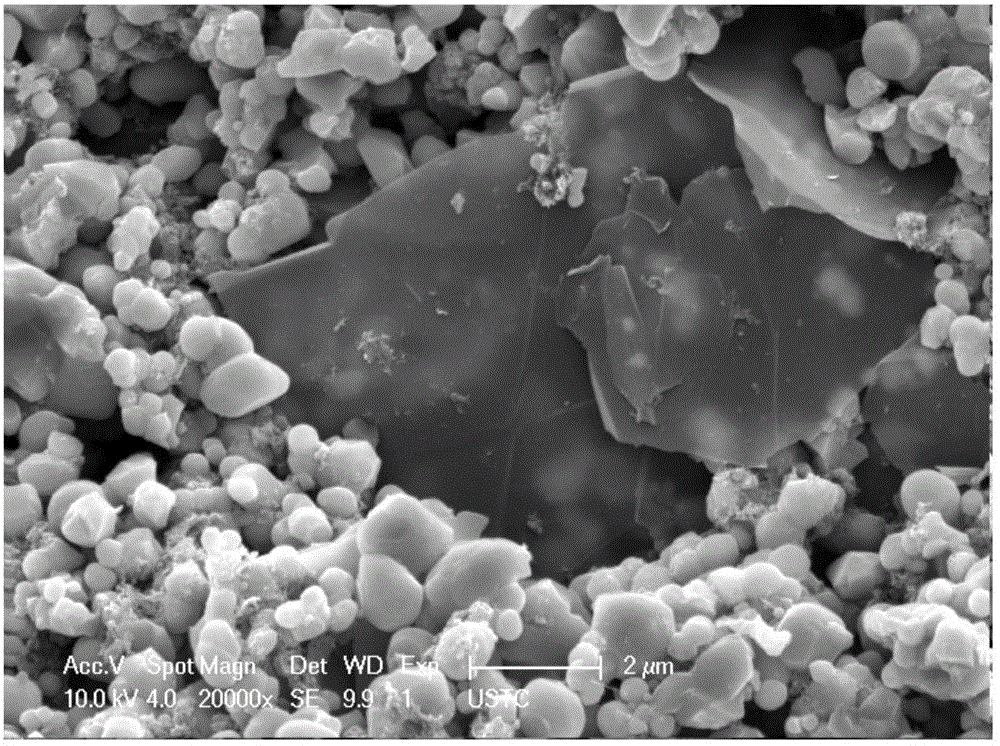

[0022] 3. The graphene oxide / lithium iron phosphate composite material was calcined at 750° C. for 12 hours under a hydrogen atmosphere to obtain a lithium iron phosphate composite material with uniformly dispersed graphene.

Embodiment 2

[0024] 1. Ultrasonically disperse graphite oxide in alcohol to obtain a graphene oxide suspension with a solid content of 5%;

[0025] 2. Add the graphene oxide suspension to the lithium iron phosphate precursor, control the amount of graphene oxide added to 1% of the mass fraction of the solute, add alcohol, adjust the solid content to 70%, and carry out wet ball milling, 40Hz ball milling for 4h, set Vacuum drying at 100°C for 24 hours, grinding to obtain graphene oxide / lithium iron phosphate composite material;

[0026] 3. The graphene oxide / lithium iron phosphate composite material was calcined at 750° C. for 12 hours under a hydrogen atmosphere to obtain a lithium iron phosphate composite material with uniformly dispersed graphene.

Embodiment 3

[0028] 1. Ultrasonically disperse graphite oxide in alcohol to obtain a graphene oxide suspension with a solid content of 10%;

[0029] 2. Add the graphene oxide suspension to the lithium iron phosphate precursor, control the amount of graphene oxide added to 0.5% of the mass fraction of the solute, add alcohol, adjust the solid content to 60%, and carry out wet ball milling, 40Hz ball milling for 4h, set Vacuum drying at 100°C for 24 hours, grinding to obtain graphene oxide / lithium iron phosphate composite material;

[0030] 3. The graphene oxide / lithium iron phosphate composite material was calcined at 750° C. for 12 hours under a hydrogen atmosphere to obtain a lithium iron phosphate composite material with uniformly dispersed graphene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com