Stabilizing agent for coconut milk beverage and method for preparing coconut milk beverage by using stabilizing agent

A technology of stabilizer and coconut water, applied in the field of coconut water beverage stabilizer and preparation of coconut water beverage by using the same, can solve the problems of subsistence, less attention to the influence of coconut water precipitation, unnatural taste, etc., and achieves thermodynamic stability and good particle size. Suspension ability, stable effect of product system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

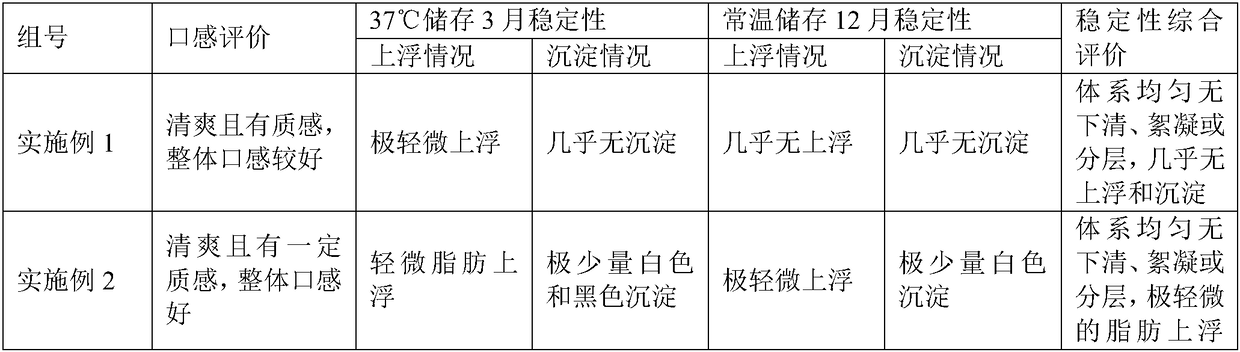

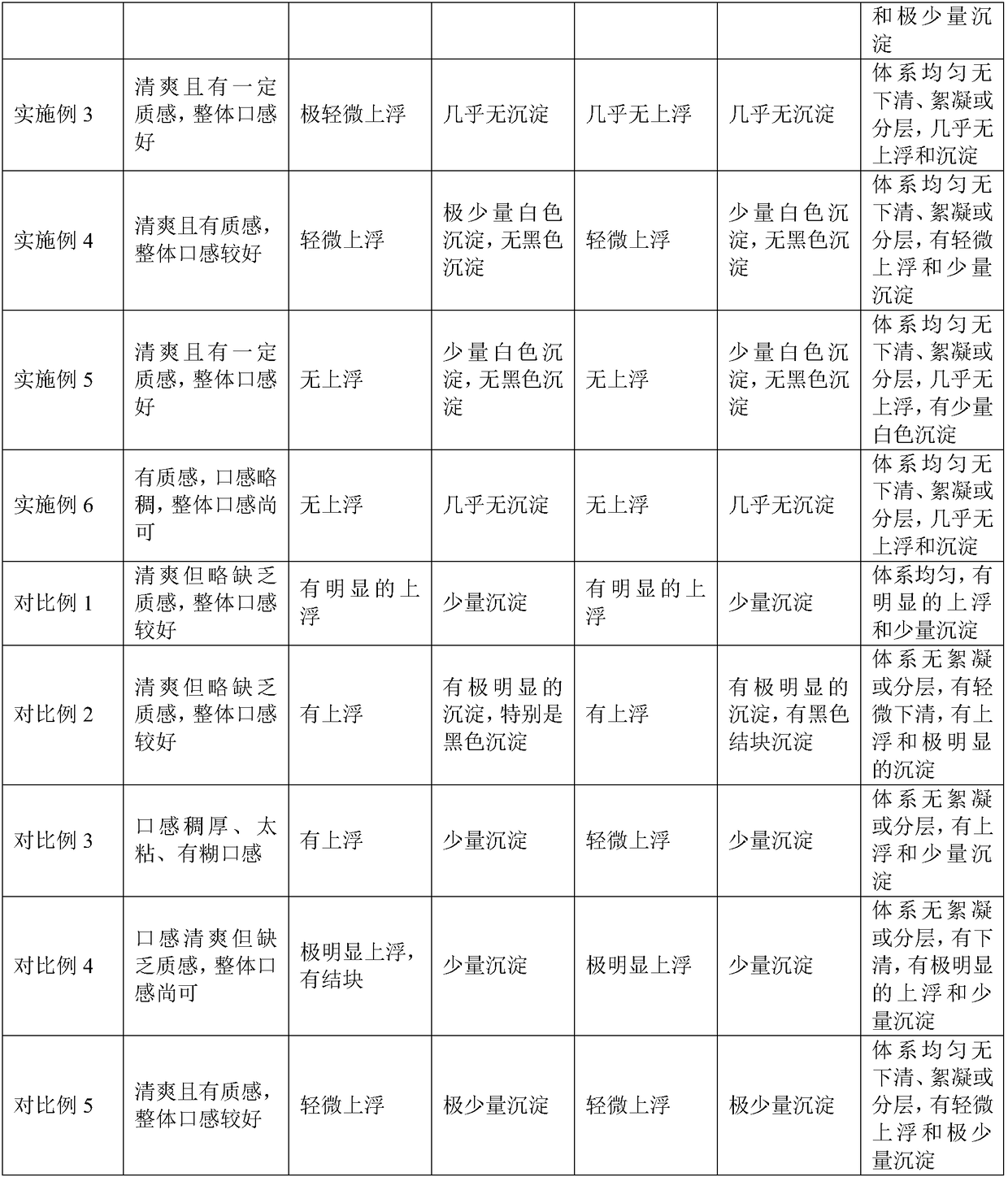

Examples

Embodiment 1

[0056] The ingredients of this embodiment are raw materials from emulsifier, thickener, acidity regulator, white granulated sugar, etc., wherein the weight of each ingredient is calculated based on the total amount of 100g: mono-, diglyceride fatty acid ester 5g, sucrose fatty acid ester 5g , sodium caseinate 6.6g, titanium dioxide 1.7g, sodium starch octenyl succinate 10g, microcrystalline cellulose 10g, xanthan gum 1g, sodium citrate 1.7g, sodium tripolyphosphate 0.2g, white sugar 58.8g.

[0057] Use this stabilizer to prepare the method for coconut milk beverage as follows:

[0058] 1) Pre-emulsification of coconut milk: Weigh 132g of coconut milk, heat it to 60°C in a water bath, add mono- and diglyceride fatty acid esters to it to disperse as the oil phase; dissolve sucrose fatty acid esters with 60g of 70°C hot water as the water phase; Slowly add the water phase to the oil phase under stirring; then dissolve sodium caseinate with 66g of 85°C hot water and add it to the ...

Embodiment 2

[0068] The ingredients of this embodiment are made of emulsifiers, thickeners, acidity regulators, white granulated sugar, etc., wherein the weight of each ingredient is calculated based on the total amount of 100g: mono- and diglyceride fatty acid esters 10g, sucrose fatty acid esters 1.7 g, sodium caseinate 23.3g, fumed silica 6g, sodium starch octenyl succinate 20g, microcrystalline cellulose 3.3g, gellan gum 1g, sodium citrate 10g, sodium tripolyphosphate 1g, white sugar 23.7 g.

[0069] Use this stabilizer to prepare the method for coconut milk beverage as follows:

[0070] 1) Pre-emulsification of coconut milk: Weigh 660g of coconut milk, heat it to 80°C in a water bath, add mono- and diglyceride fatty acid esters to it to disperse as the oil phase; dissolve sucrose fatty acid esters with hot water at 300-965°C as the water phase; Slowly add the water phase to the oil phase under stirring; then dissolve sodium caseinate with 100g of 80°C hot water and add to the aforeme...

Embodiment 3

[0080] The ingredients of this example are made of emulsifiers, thickeners, acidity regulators, white granulated sugar, etc., wherein the weight of each ingredient is calculated based on the total amount of 100g: mono- and diglyceride fatty acid esters 10g, sucrose fatty acid esters 3.3 g, sodium caseinate 23.3g, fumed silica 10g, sodium starch octenyl succinate 20g, microcrystalline cellulose 3.3g, xanthan gum 2.3g, potassium citrate 8.3g, sodium tripolyphosphate 0.3g, White granulated sugar 19.2g.

[0081] Use this stabilizer to prepare the method for coconut milk beverage as follows:

[0082] 1) Pre-emulsification of coconut milk: Weigh 330g of coconut milk, heat it to 70°C in a water bath, add mono- and diglyceride fatty acid esters to it to disperse as an oil phase; dissolve sucrose fatty acid esters with 100g of 65°C hot water as an aqueous phase; Slowly add the water phase to the oil phase under stirring; then dissolve sodium caseinate with 100g of 80°C hot water and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com