Novel combined sedimentation tank

A compound type, sedimentation tank technology, applied in the direction of sedimentation separation, sedimentation tank, sedimentation tank, etc., can solve the problem of sludge floating in the sedimentation tank and excessive suspended solids in effluent, reducing sludge floating and suspended solids content in effluent, poor sedimentation effect, etc. It can reduce the generation of sludge and floating sludge, ensure the quality of effluent, and ensure the effect of treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

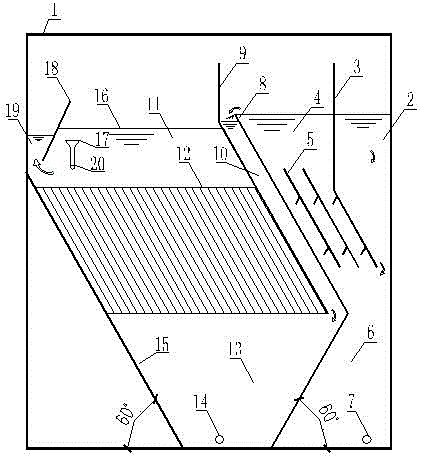

[0014] Such as figure 1 As shown, a new compound sedimentation tank of the present invention includes, pre-sedimentation area (4), water distribution area (10), fine sedimentation area (11), outlet channel (19), distribution channel (2) and pre-settling area (4) Connected by the first baffle plate (3); the pre-settling area (4) is equipped with an inclined plate settler (5), and the bottom of the pre-settling area (4) is equipped with a sludge thickening bucket (6) and a drain The mud port (7); the pre-sedimentation area (4) is connected with the water distribution area (10) through the second baffle (8), and the water distribution area (10) and the fine sedimentation area (11) are connected through the third baffle (9) ) connected; the fine settling area (11) is equipped with an inclined tube settler (12), the bottom of the fine settling area (11) is equipped with a sludge thickening bucket (13) and a sludge discharge port (14), and the upper part is equipped with a floating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com